The primary advantages of NBR seat butterfly valves are their excellent resistance to oils and hydrocarbons, significant cost-effectiveness, and reliable flexibility. This combination makes Nitrile Butadiene Rubber (NBR) a practical and economical choice for a wide range of general-purpose and industrial applications operating under moderate conditions.

The decision to use an NBR seat butterfly valve is fundamentally a choice for a reliable, budget-friendly sealing solution in systems where oils, fuels, or fats are present, but extreme temperatures and aggressive chemicals are not a concern.

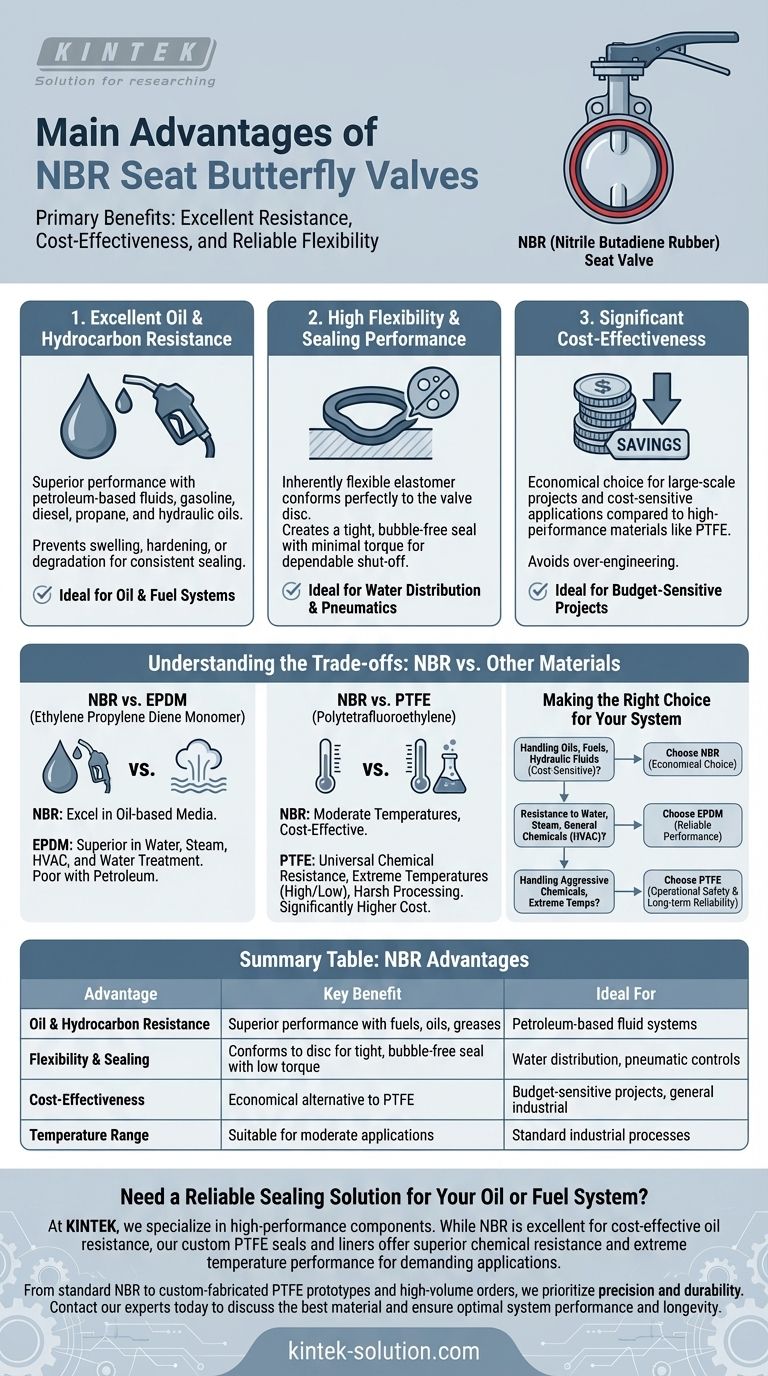

The Core Strengths of NBR Seats

Understanding the specific properties of NBR helps clarify why it is so widely used in certain industrial contexts. Its performance is defined by a balance of resistance, flexibility, and cost.

Excellent Resistance to Oils and Hydrocarbons

The standout feature of NBR is its superior performance in the presence of petroleum-based fluids. This includes gasoline, diesel fuel, propane, and various hydraulic oils.

This resistance prevents the material from swelling, hardening, or degrading, which ensures the valve maintains a consistent and reliable seal over its service life in these specific environments.

High Flexibility and Sealing Performance

As an elastomer (rubber), NBR is inherently flexible and resilient. This allows the seat to conform perfectly to the valve disc, creating a tight, bubble-free seal with minimal torque.

This property is crucial for applications requiring dependable shut-off, such as in water distribution or pneumatic control systems.

Significant Cost-Effectiveness

Compared to high-performance materials like PTFE, NBR is a much more economical option. This makes it the default choice for large-scale projects or cost-sensitive applications where its operational limitations are not a factor.

For many standard industrial processes, NBR provides all the necessary performance without the expense of over-engineering the solution.

Understanding the Trade-offs: NBR vs. Other Materials

Choosing NBR is as much about understanding its limitations as it is about its strengths. Its performance must be weighed against other common seat materials to ensure it is the right fit for the operational environment.

NBR vs. EPDM

EPDM (Ethylene Propylene Diene Monomer) seats offer superior resistance to water, steam, ketones, and some acids. They are a top choice for water treatment and HVAC systems.

However, EPDM performs poorly with petroleum-based oils and hydrocarbons, which is precisely where NBR excels. The choice between them often comes down to this single factor: water-based media (EPDM) vs. oil-based media (NBR).

NBR vs. PTFE

PTFE (Polytetrafluoroethylene) is a high-performance fluoropolymer known for its nearly universal chemical resistance and ability to handle extreme temperatures, both high and low.

While NBR is limited to moderate temperatures, PTFE is the clear choice for harsh chemical processing or cryogenic applications. This superior performance, however, comes at a significantly higher cost.

Making the Right Choice for Your System

Selecting the correct valve seat material is critical for ensuring system longevity, safety, and efficiency. Your decision should be based directly on your application's specific chemical, thermal, and budgetary requirements.

- If your primary focus is handling oils, fuels, or hydraulic fluids in a cost-sensitive project: NBR is the ideal and most economical choice.

- If your primary focus is resistance to water, steam, or general chemicals found in HVAC and water treatment: EPDM will provide more reliable and durable performance.

- If your primary focus is handling aggressive chemicals or extreme temperatures: PTFE is the necessary investment for operational safety and long-term reliability.

Ultimately, selecting the right valve seat is about precisely matching the material's strengths to your specific operational demands.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Oil & Hydrocarbon Resistance | Superior performance with fuels, hydraulic oils, and greases | Petroleum-based fluid systems |

| Flexibility & Sealing | Conforms to disc for a tight, bubble-free seal with low torque | Water distribution, pneumatic controls |

| Cost-Effectiveness | Economical alternative to high-performance materials like PTFE | Budget-sensitive projects, general industrial use |

| Temperature Range | Suitable for moderate temperature applications | Standard industrial processes |

Need a Reliable Sealing Solution for Your Oil or Fuel System?

At KINTEK, we specialize in manufacturing high-performance components, including custom PTFE seals and liners for demanding applications in the semiconductor, medical, and industrial sectors. While NBR is an excellent choice for cost-effective oil resistance, our PTFE components offer superior chemical resistance and extreme temperature performance for harsher environments.

Whether you require standard NBR valves or custom-fabricated PTFE solutions—from prototypes to high-volume orders—we prioritize precision and durability.

Contact our experts today to discuss the best material for your specific application and ensure optimal system performance and longevity.

Visual Guide

Related Products

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the common applications of PTFE diaphragms in the Chinese market? Key Uses in Chemical, Pharma & Semiconductor

- What are the main technical features that influence the performance of PTFE diaphragms? Optimize for Durability & Chemical Resistance

- What industries commonly use PTFE lined diaphragm valves and why? Ensure Purity & Corrosion Resistance

- What are the key properties of PTFE that benefit bellows and diaphragms? Achieve Unmatched Reliability in Harsh Environments

- What makes PTFE-lined diaphragm valves suitable for wastewater treatment? Ensure Reliability and Cost Savings