The load-bearing capacity of Polytetrafluoroethylene (PTFE) sheets is typically specified in the range of 130-140 kg/cm². However, this number represents only one aspect of its mechanical performance. To use PTFE effectively in an engineering context, you must understand this compressive strength in relation to its other defining characteristics, such as its extreme softness and uniquely low friction.

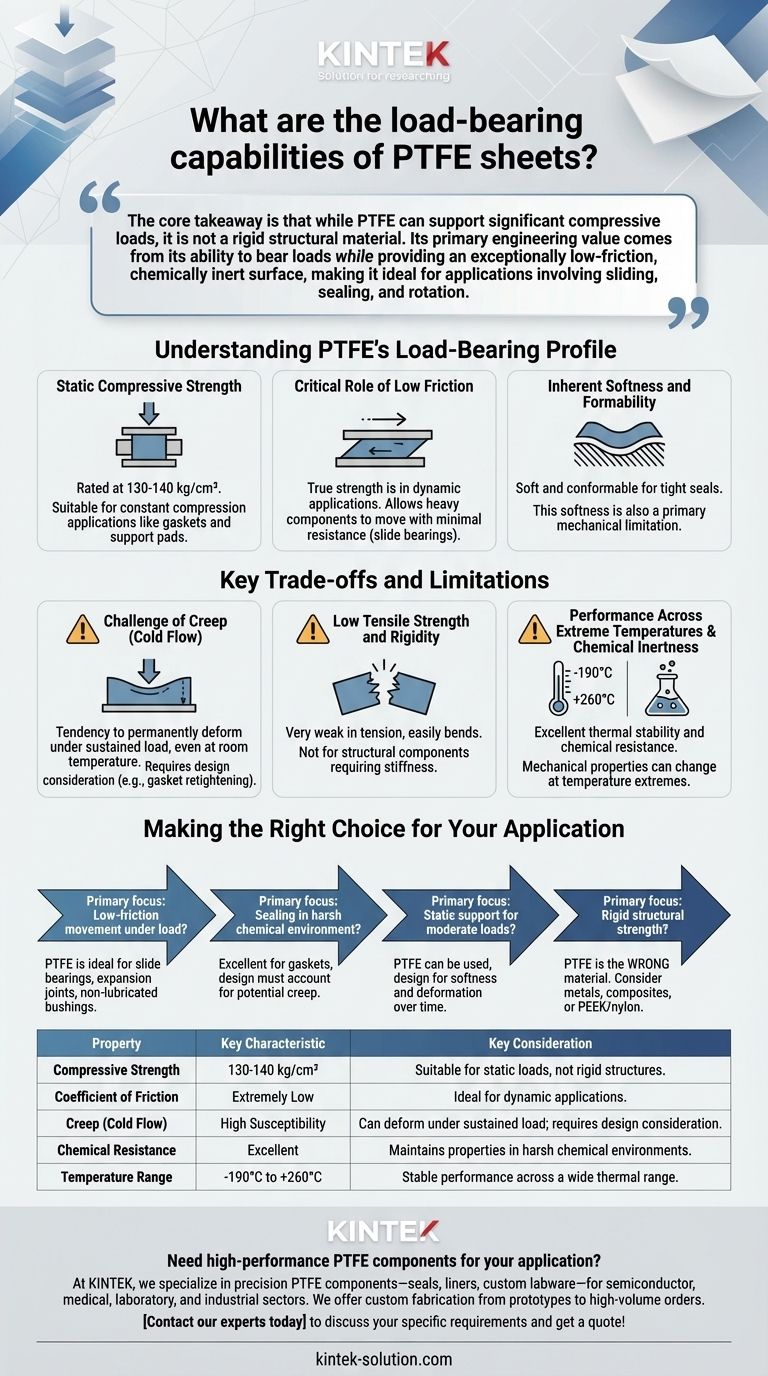

The core takeaway is that while PTFE can support significant compressive loads, it is not a rigid structural material. Its primary engineering value comes from its ability to bear loads while providing an exceptionally low-friction, chemically inert surface, making it ideal for applications involving sliding, sealing, and rotation.

Understanding PTFE's Load-Bearing Profile

When evaluating a material, "load-bearing" isn't a single property but a profile of behaviors. PTFE's profile is highly specialized, making it an excellent choice for some applications and a poor choice for others.

The Static Compressive Strength

PTFE's ability to resist a static, crushing force is rated at 130-140 kg/cm². This makes it suitable for applications where it is placed under constant compression, such as in certain types of gaskets or support pads.

The Critical Role of Low Friction

PTFE's most famous property is its incredibly low coefficient of friction—it is one of the most slippery solid materials known. Its true load-bearing strength is in dynamic applications where it must support a weight that is also moving, such as a slide bearing for a bridge or a pipeline support.

In these cases, PTFE allows heavy components to move with minimal resistance, reducing stress and eliminating the need for traditional lubrication.

Inherent Softness and Formability

Unlike metals or rigid plastics, PTFE is a relatively soft material. This allows it to conform to irregular surfaces, which is highly beneficial for creating tight seals in gaskets and flanges.

However, this softness is also its primary mechanical limitation.

Key Trade-offs and Limitations

Using PTFE effectively means designing around its inherent trade-offs. Its strengths in one area create challenges that must be managed.

The Challenge of Creep (Cold Flow)

Because it is a soft material, PTFE is susceptible to creep, also known as cold flow. This is the tendency for the material to slowly deform permanently when held under a sustained load, even at room temperature.

For a bolted gasket, this means the initial bolt torque may lessen over time as the PTFE "flows" away from the pressure point, potentially requiring retightening. For a precision bearing, creep can lead to a loss of critical tolerances.

Low Tensile Strength and Rigidity

While PTFE performs well under compression, it is very weak in tension (being pulled apart). It is not a rigid material and will easily bend and deform.

It should never be used for structural components that require stiffness or tensile strength.

Performance Across Extreme Temperatures

PTFE maintains its properties over an exceptionally wide temperature range, from -190°C to +260°C. This thermal stability is a major advantage, but its mechanical properties, including its resistance to creep, can change at the extremes of this range.

Unmatched Chemical Inertness

A significant advantage is that PTFE's mechanical capabilities are not degraded by exposure to nearly all industrial chemicals, acids, and solvents. It can bear loads in environments that would destroy most other materials.

Making the Right Choice for Your Application

Use these guidelines to determine if PTFE is the correct material for your specific goal.

- If your primary focus is low-friction movement under load: PTFE is an ideal choice for slide bearings, expansion joints, and non-lubricated bushings.

- If your primary focus is sealing in a harsh chemical environment: PTFE's compressive strength and chemical inertness make it excellent for gaskets, provided the design accounts for potential creep.

- If your primary focus is static support for moderate loads: PTFE can be used, but you must design for its softness and tendency to deform over time under sustained pressure.

- If your primary focus is rigid structural strength: PTFE is the wrong material; you should consider metals, composites, or more rigid engineering plastics like PEEK or nylon.

By understanding PTFE's unique balance of compressive strength, softness, and low friction, you can leverage it effectively in the most demanding engineering applications.

Summary Table:

| Property | Key Characteristic | Key Consideration |

|---|---|---|

| Compressive Strength | 130-140 kg/cm² | Suitable for static loads, but not for rigid structures. |

| Coefficient of Friction | Extremely Low | Ideal for dynamic applications like bearings. |

| Creep (Cold Flow) | High Susceptibility | Can deform under sustained load; requires design consideration. |

| Chemical Resistance | Excellent | Maintains properties in harsh chemical environments. |

| Temperature Range | -190°C to +260°C | Stable performance across a wide thermal range. |

Need high-performance PTFE components for your application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your parts are designed to leverage PTFE's strengths while mitigating its limitations like creep.

We offer custom fabrication from prototypes to high-volume orders, guaranteeing the quality and reliability your projects demand.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs