At its core, Teflon (PTFE) plastic sheet is defined by three exceptional properties. It possesses unmatched chemical resistance, an extremely low coefficient of friction, and remarkable stability across a wide range of temperatures. These characteristics stem from its unique molecular structure—a strong chain of carbon atoms completely shielded by fluorine atoms.

The true value of Teflon lies not in any single property, but in their powerful combination. This synergy creates a high-performance material that remains stable and functional in extreme environments where most other plastics would fail.

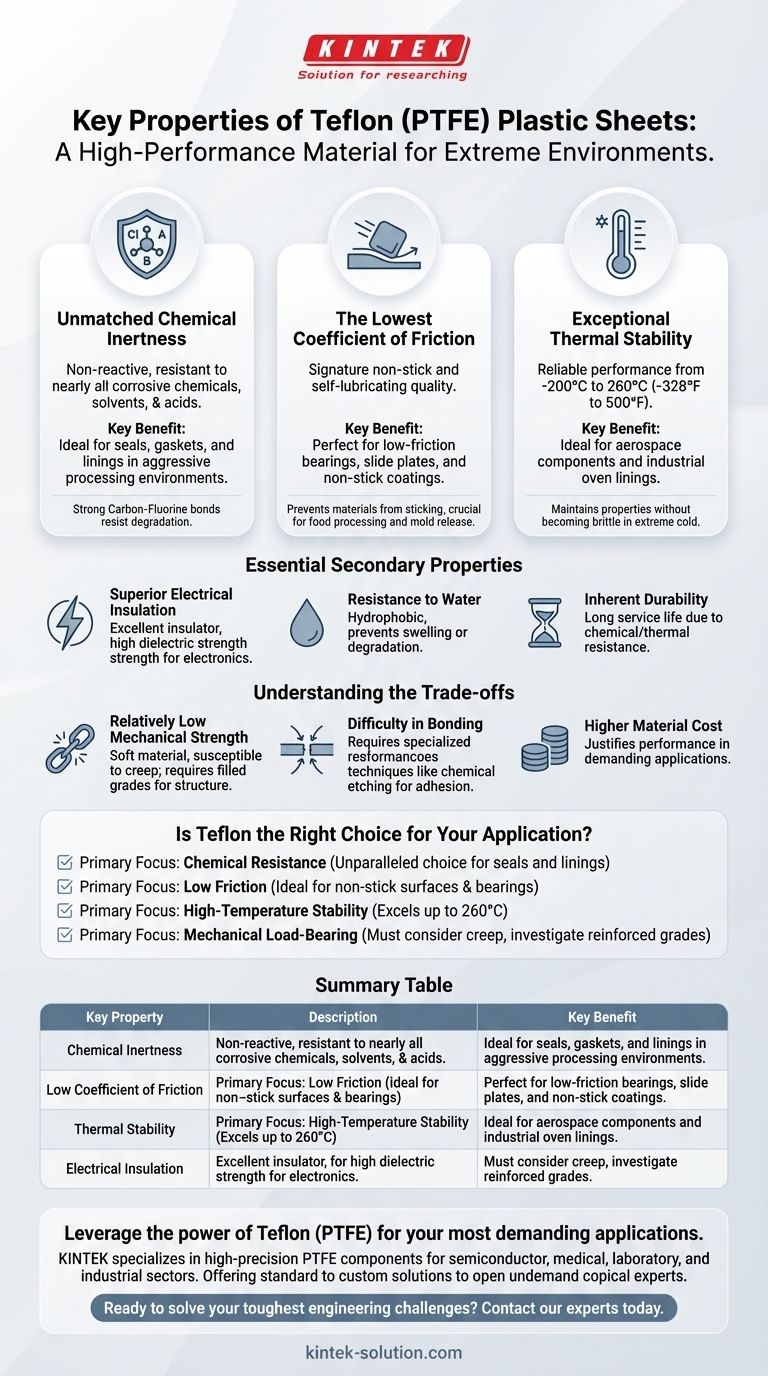

The Foundational Pillars of Teflon's Performance

Understanding the primary characteristics of Teflon (polytetrafluoroethylene) is key to leveraging it effectively in any industrial or technical application. These three pillars are what make it a go-to material for solving difficult engineering challenges.

Unmatched Chemical Inertness

Teflon is famously non-reactive and resistant to nearly all corrosive chemicals, solvents, and acids.

This inertness is due to the incredibly strong carbon-fluorine bonds that make up its molecular backbone. These bonds are difficult for other chemicals to break, protecting the material from degradation.

Only a few highly reactive substances, like molten alkali metals, can affect it. This makes it ideal for seals, gaskets, and linings in aggressive chemical processing environments.

The Lowest Coefficient of Friction

Teflon has one of the lowest coefficients of friction of any known solid material, giving it its signature non-stick and self-lubricating quality.

This means surfaces move against it with minimal resistance. This property is invaluable for applications like low-friction bearings, slide plates, and non-stick coatings where smooth, effortless motion is critical.

The anti-adhesion quality also prevents materials from sticking to its surface, which is crucial in food processing, mold release, and handling viscous substances.

Exceptional Thermal Stability

Teflon performs reliably across an exceptionally broad temperature range.

It maintains its properties in continuous service at temperatures up to 260°C (500°F) and can withstand cryogenic temperatures as low as -200°C (-328°F) without becoming brittle.

This thermal stability allows it to be used in applications involving extreme heat or cold, from aerospace components to industrial oven linings.

Essential Secondary Properties

Beyond the main three, several other characteristics contribute to Teflon's versatility and performance.

Superior Electrical Insulation

Teflon is an excellent electrical insulator with very high dielectric strength and bulk resistivity.

Its strong carbon-fluorine bonds do not allow for the easy flow of electrons, making it a preferred material for high-frequency applications, cable insulation, and circuit boards.

Resistance to Water

Teflon is hydrophobic, meaning it repels water and resists moisture absorption.

This property ensures that its mechanical and electrical properties remain stable even in humid or wet environments, preventing swelling or degradation due to moisture.

Inherent Durability

While not exceptionally hard, Teflon is a durable and reusable material. Its chemical and thermal resistance means it does not degrade easily, giving it a very long service life in the right applications.

Understanding the Trade-offs

No material is perfect. To use Teflon effectively, you must understand its limitations.

Relatively Low Mechanical Strength

Compared to engineering plastics like nylon or PEEK, standard Teflon is a relatively soft material.

It can be susceptible to creep (slow deformation under a sustained load) and has lower tensile strength and abrasion resistance. For structural applications, filled grades of PTFE are often required to enhance mechanical properties.

Difficulty in Bonding

The same non-stick properties that make Teflon so useful also make it very difficult to bond to other surfaces using conventional adhesives. Specialized surface preparation techniques, such as chemical etching, are required to achieve a strong bond.

Higher Material Cost

As a high-performance fluoropolymer, Teflon is typically more expensive than common commodity plastics. Its cost is justified by its unique performance capabilities in demanding applications where other materials would not survive.

Is Teflon the Right Choice for Your Application?

Choosing Teflon depends entirely on whether its unique strengths align with your primary engineering goal.

- If your primary focus is chemical resistance: Teflon is an unparalleled choice for seals, linings, and components exposed to corrosive substances.

- If your primary focus is low friction: It is the ideal material for non-stick surfaces, self-lubricating bearings, and slide plates.

- If your primary focus is high-temperature stability: It excels in applications that require consistent performance at temperatures up to 260°C (500°F).

- If your primary focus is mechanical load-bearing: You must carefully consider its softness and potential for creep, and investigate reinforced or filled grades of PTFE.

Teflon is a specialized material designed to solve problems of friction, heat, and chemical attack that are beyond the scope of ordinary plastics.

Summary Table:

| Key Property | Description | Key Benefit |

|---|---|---|

| Chemical Inertness | Resistant to nearly all corrosive chemicals and solvents. | Ideal for seals and linings in aggressive environments. |

| Low Coefficient of Friction | One of the lowest of any solid material; self-lubricating. | Perfect for non-stick surfaces and low-friction bearings. |

| Thermal Stability | Performs from -200°C to 260°C (-328°F to 500°F). | Reliable in extreme heat or cryogenic applications. |

| Electrical Insulation | High dielectric strength and bulk resistivity. | Excellent for high-frequency circuits and cable insulation. |

Leverage the power of Teflon (PTFE) for your most demanding applications.

Teflon's unique combination of properties makes it the ideal solution for challenges involving extreme heat, corrosive chemicals, or the need for minimal friction. At KINTEK, we specialize in manufacturing high-precision PTFE components—including custom sheets, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

Whether you need a standard solution or a custom-fabricated part from prototype to high-volume production, our expertise ensures you get a component that delivers superior performance and longevity.

Ready to solve your toughest engineering challenges? Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry