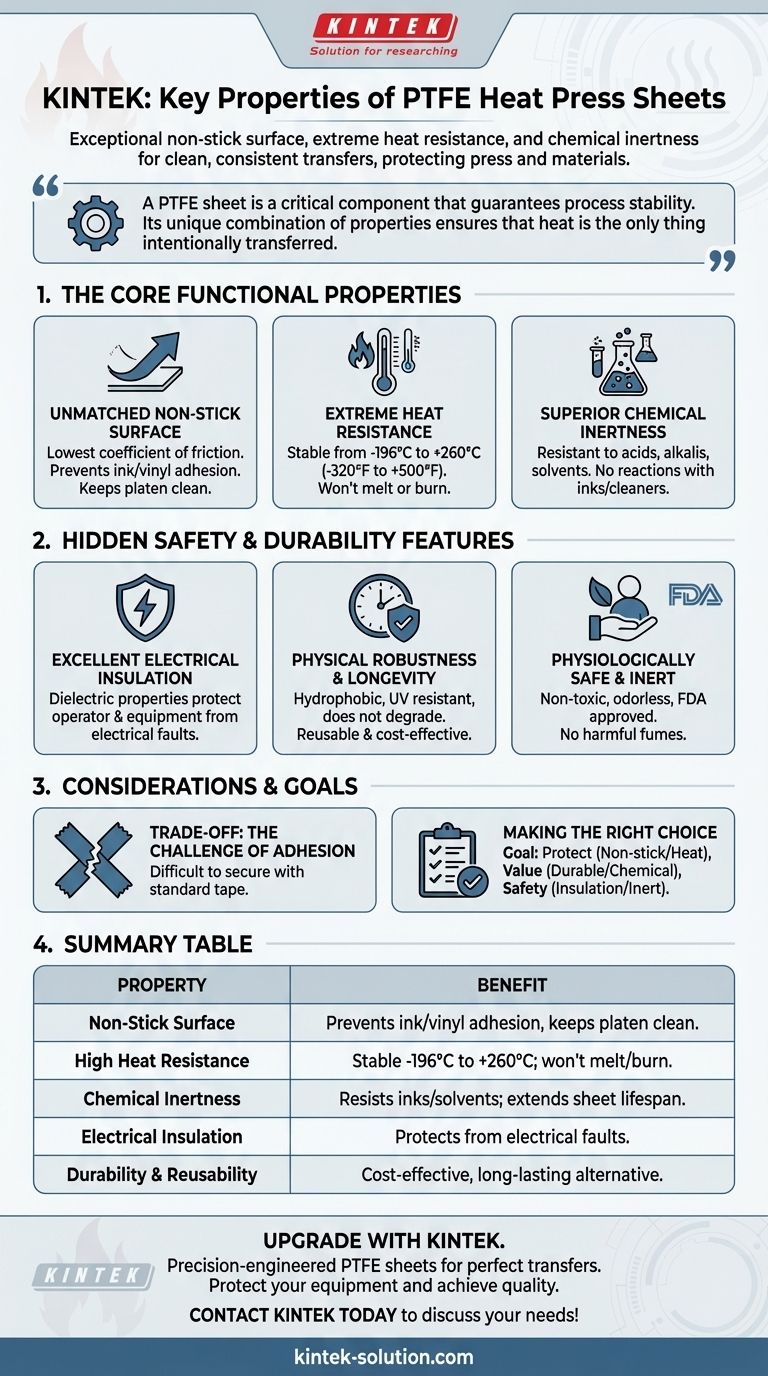

In short, the key properties of PTFE heat press sheets are their exceptional non-stick surface, extreme heat resistance, and chemical inertness. These characteristics make them an indispensable tool for protecting both your heat press and the materials you are working with, ensuring a clean and consistent transfer every time.

A PTFE sheet is not just a protective layer; it's a critical component that guarantees process stability. Its unique combination of properties ensures that heat is the only thing intentionally transferred, preventing adhesion, contamination, and electrical faults.

The Core Functional Properties

To understand the value of a PTFE sheet, we must look at the three properties that directly impact the heat transfer process. These features work in concert to deliver a predictable and high-quality result.

Unmatched Non-Stick Surface

PTFE is famously known for having one of the lowest coefficients of friction of any solid material. For heat press applications, this means inks, adhesives, and vinyls will not stick to the sheet.

This prevents the design from being lifted off the garment and keeps the upper platen of your heat press clean from residue.

Extreme Heat Resistance

PTFE maintains its integrity across a vast temperature range, typically from -196°C to +260°C (-320°F to +500°F).

This high tolerance ensures the sheet will not melt, burn, or degrade at standard heat pressing temperatures, providing a stable and safe barrier.

Superior Chemical Inertness

This material is highly resistant to virtually all industrial chemicals, including acids, alkalis, and solvents.

This property guarantees that the sheet will not react with any inks, dyes, or cleaning agents you might use, extending its lifespan and preventing any unwanted chemical reactions that could damage your project.

The Hidden Safety and Durability Features

Beyond the primary functions, other intrinsic properties of PTFE contribute to its reliability, safety, and long-term value as a workshop tool.

Excellent Electrical Insulation

PTFE has outstanding dielectric properties, meaning it is an excellent electrical insulator.

This acts as a critical safety feature, helping to protect the operator and the equipment from potential electrical shorts or faults within the heat press.

Physical Robustness and Longevity

The material is hydrophobic (repels water), resistant to UV light, and does not degrade with age. These qualities make the sheets highly durable and reusable.

This reusability provides significant cost-effectiveness over time compared to disposable alternatives like parchment paper.

Physiologically Safe and Inert

PTFE is non-toxic, odorless, and physiologically harmless. It is widely approved for food contact applications (FDA approved).

This ensures it does not release harmful fumes or substances during the heating process, contributing to a safer working environment.

Understanding the Trade-offs

No material is perfect for every scenario. Being objective about PTFE's limitations is key to using it effectively.

The Challenge of Adhesion

The same non-stick property that makes PTFE so valuable also means that almost nothing sticks to it.

This can be a minor inconvenience when trying to secure the sheet with heat-resistant tape, as most adhesives will not form a strong bond with its surface.

Making the Right Choice for Your Goal

Your primary goal will determine which properties of PTFE are most critical to your work.

- If your primary focus is protecting garments and transfers: The non-stick surface and high heat resistance are the most important features for you.

- If your primary focus is ensuring long-term value: Its chemical resistance, physical durability, and reusability make it a wise investment.

- If your primary focus is a safe working environment: The material's non-toxic nature and excellent electrical insulation provide essential peace of mind.

Ultimately, choosing a PTFE sheet is an investment in the quality of your work and the longevity of your equipment.

Summary Table:

| Property | Benefit for Heat Pressing |

|---|---|

| Non-Stick Surface | Prevents ink/vinyl adhesion, keeps platen clean. |

| High Heat Resistance | Stable from -196°C to +260°C; won't melt or burn. |

| Chemical Inertness | Resists inks and solvents; extends sheet lifespan. |

| Electrical Insulation | Protects operator and equipment from electrical faults. |

| Durability & Reusability | Cost-effective, long-lasting alternative to parchment paper. |

Upgrade your heat press process with precision-engineered PTFE sheets from KINTEK.

Our PTFE components are manufactured to the highest standards, ensuring the exceptional non-stick performance, heat resistance, and durability detailed in this article. Whether you need a standard size or a custom-fabricated solution for high-volume orders, KINTEK delivers the quality and reliability that specialized industries count on.

Protect your equipment and achieve perfect transfers every time. Contact KINTEK today to discuss your PTFE sheet needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability