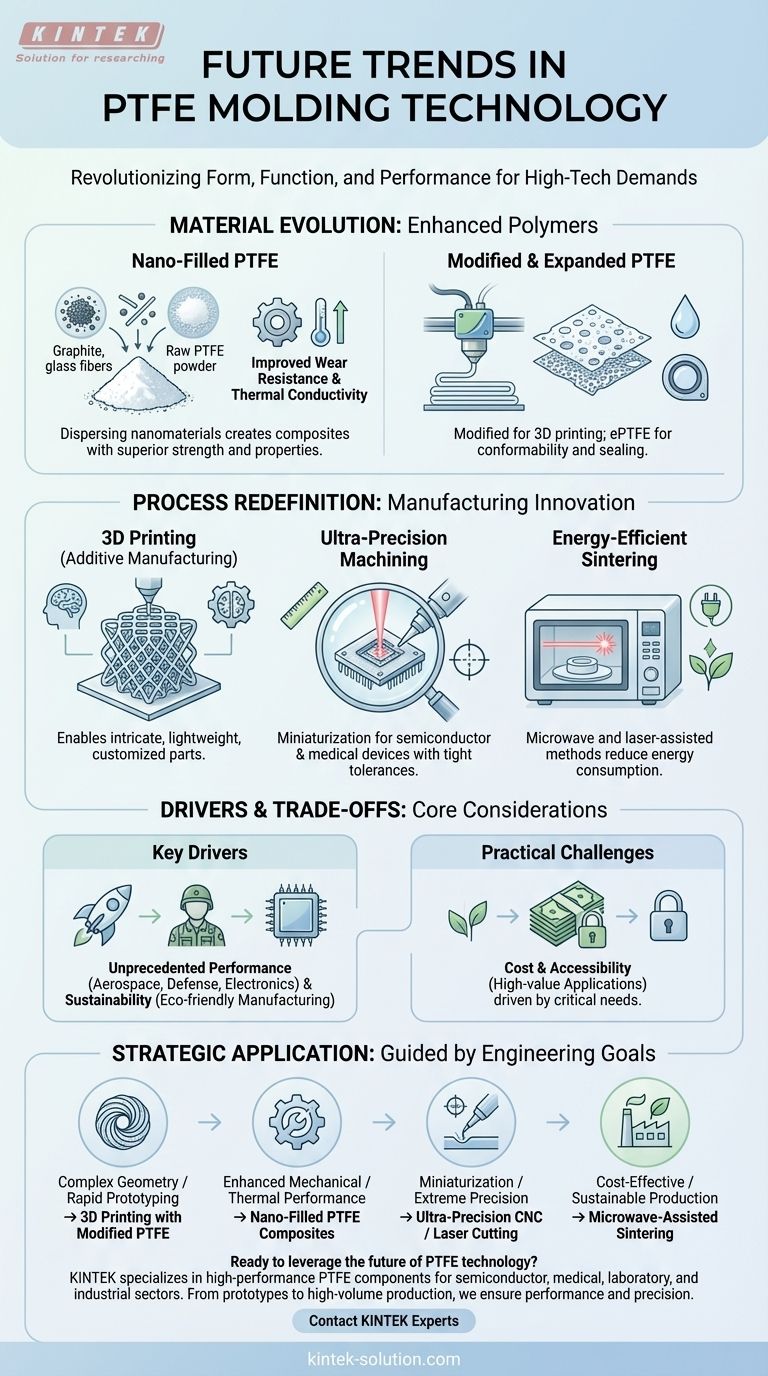

The future of PTFE molding is not about changing the core material, but revolutionizing how it's formed and what it can do. The key trends are a direct response to increasing demands from high-tech industries. We are seeing a definitive shift toward 3D printing for complex shapes, the integration of nanomaterials to enhance physical properties, the adoption of ultra-precision manufacturing for miniaturization, and the development of energy-efficient, sustainable production methods.

The core challenge with traditional PTFE is its resistance to conventional melt processing and its inherent limitations in wear and thermal conductivity. Future trends are not isolated developments; they are a coordinated effort to overcome these exact weaknesses, unlocking PTFE's use in applications that were previously impossible.

The Evolution of the Material Itself

The foundation of future PTFE components lies in enhancing the polymer before the molding process even begins. This involves creating advanced composites that target specific performance weaknesses.

The Rise of Nano-Filled PTFE

Standard PTFE exhibits high wear and low thermal conductivity. By introducing fillers, we fundamentally change these properties.

Nano-filled PTFE involves dispersing microscopic particles like graphite, glass fiber, or other nanomaterials into the raw PTFE powder. This creates a composite material with dramatically improved wear resistance, strength, and thermal conductivity.

Modified and Expanded PTFE

Beyond fillers, the base polymer itself is being altered. Modified PTFE is often a key enabler for newer processes like 3D printing, improving its flow and forming characteristics.

Simultaneously, materials like Expanded PTFE (ePTFE) offer superior conformability and sealing capabilities, making them ideal for high-performance gaskets and seals in irregular applications.

Redefining the Manufacturing Process

How a PTFE part is made is becoming just as important as what it's made of. New techniques are solving long-standing challenges related to geometry, precision, and efficiency.

Additive Manufacturing (3D Printing)

Traditional compression molding is excellent for simple shapes but struggles with complex geometries. 3D printing of PTFE is the solution, enabling the creation of intricate, lightweight, and highly customized parts that are impossible to produce otherwise.

Ultra-Precision Machining

For industries like semiconductors and medical devices, miniaturization is critical. Ultra-precision machining and laser cutting allow for the fabrication of tiny components with exceptionally tight tolerances, meeting the demand for smaller and more accurate parts.

Energy-Efficient Sintering

The sintering phase, where the molded part is heated to fuse the particles, is traditionally the most energy-intensive step. New methods like microwave-assisted and laser-assisted sintering promise to dramatically reduce energy consumption and production time, making the process more sustainable and cost-effective.

Understanding the Core Drivers and Trade-offs

These advancements are not happening in a vacuum. They are driven by clear industry needs but also come with practical considerations.

The Push for Unprecedented Performance

The primary driver is the demand from sectors like aerospace, defense, and electronics. These fields require components that can withstand extreme temperatures, corrosive chemicals, and intense mechanical stress—pushing beyond the limits of standard PTFE.

Sustainability as a Key Factor

There is a growing emphasis on environmentally responsible manufacturing. Energy-efficient sintering and more precise manufacturing methods that reduce waste are becoming crucial selling points and, in some cases, regulatory requirements.

The Challenge of Cost and Accessibility

These advanced technologies are powerful but come at a premium. The cost of nano-filled materials, specialized 3D printers, and precision machinery means they are currently reserved for high-value applications where performance justifies the expense.

How to Apply This to Your Project

Your choice of technology should be guided entirely by your primary engineering goal.

- If your primary focus is complex geometry or rapid prototyping: Your best path is to investigate 3D printing services that work with modified PTFE compounds.

- If your primary focus is enhanced mechanical or thermal performance: You should specify nano-filled or glass-fiber-filled PTFE composites from the outset.

- If your primary focus is miniaturization and extreme precision: Your project requires a manufacturing partner with proven expertise in ultra-precision CNC machining or laser cutting of PTFE.

- If your primary focus is cost-effective, high-volume production with an eye on sustainability: You should monitor the maturation of microwave-assisted sintering for traditional molding processes.

By understanding these advancements, you can anticipate future capabilities and select the right PTFE technology to solve tomorrow's most demanding engineering challenges.

Summary Table:

| Trend | Key Benefit | Ideal For |

|---|---|---|

| 3D Printing / Additive Manufacturing | Complex geometries, rapid prototyping | Custom, intricate parts impossible with traditional molding |

| Nano-Filled PTFE Composites | Enhanced wear resistance, strength, thermal conductivity | High-performance applications in harsh environments |

| Ultra-Precision Machining | Extreme miniaturization, tight tolerances | Semiconductor, medical device components |

| Energy-Efficient Sintering | Reduced energy consumption, sustainable production | Cost-effective and eco-friendly high-volume manufacturing |

Ready to leverage the future of PTFE technology for your project?

At KINTEK, we specialize in manufacturing high-performance PTFE components—from seals and liners to custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype via advanced 3D printing, a high-volume order using sustainable methods, or ultra-precision parts for miniaturized applications, our expertise in custom fabrication ensures you get a solution that meets your exact performance and precision requirements.

Contact us today to discuss how our PTFE molding capabilities can solve your most demanding engineering challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support