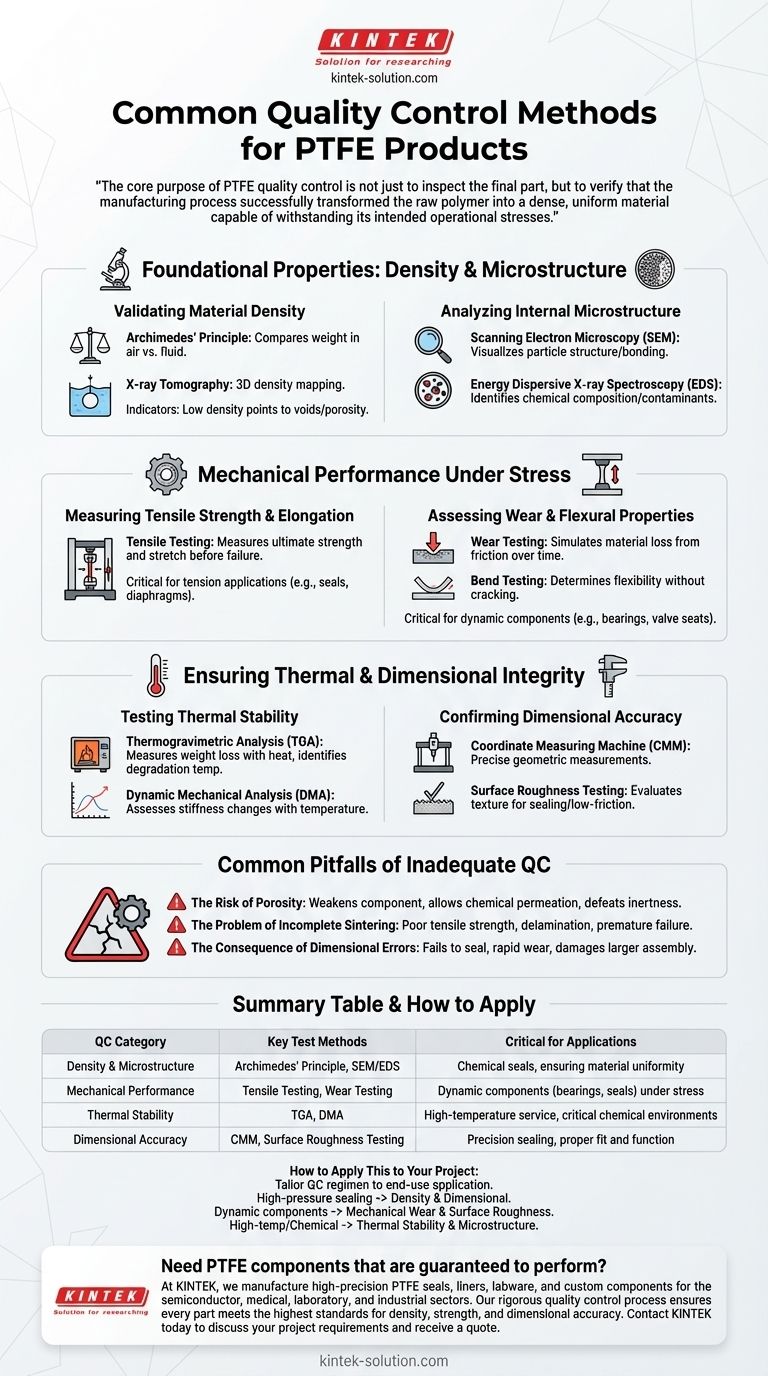

The most common quality control methods for PTFE products focus on five key areas: density, mechanical properties, microstructure, thermal stability, and dimensional accuracy. These tests are essential because the final performance of a PTFE component depends heavily on the quality of the manufacturing process, particularly the molding and sintering stages.

The core purpose of PTFE quality control is not just to inspect the final part, but to verify that the manufacturing process successfully transformed the raw polymer into a dense, uniform material capable of withstanding its intended operational stresses.

Foundational Properties: Density and Microstructure

The most fundamental indicators of a well-produced PTFE part are its density and internal structure. These attributes directly reflect how well the raw material was consolidated and fused during manufacturing.

Validating Material Density

Density is the primary indicator of proper sintering—the process of fusing PTFE particles together with heat. Low or inconsistent density points to voids or porosity within the material.

The most common method is Archimedes’ principle, which compares the part's weight in air to its weight when submerged in a fluid. For more advanced analysis, X-ray tomography can create a 3D map of density variations.

Analyzing Internal Microstructure

A microscopic examination reveals how uniformly the PTFE particles have bonded. This is critical for ensuring material homogeneity and identifying potential contaminants.

Scanning Electron Microscopy (SEM) provides high-magnification images of the part's cross-section to visualize the particle structure. It can be paired with Energy Dispersive X-ray Spectroscopy (EDS) to identify the chemical composition of any foreign materials or fillers.

Mechanical Performance Under Stress

These tests ensure the final product can withstand the physical forces it will encounter in its application, from stretching and bending to friction and abrasion.

Measuring Tensile Strength and Elongation

Tensile testing is the most common mechanical test. It involves pulling a sample of the material until it breaks, measuring its ultimate strength and how much it can stretch before failing.

This data is crucial for applications where the part will be under tension, such as in seals or diaphragms.

Assessing Wear and Flexural Properties

For dynamic components like bearings or valve seats, wear and flexibility are paramount.

Wear testing measures material loss from friction over time, simulating the component's operational life. Bend testing determines the material's ability to flex without cracking or breaking.

Ensuring Thermal and Dimensional Integrity

Even if a part has good density and strength, it must also perform reliably at its service temperature and meet precise geometric specifications to function correctly.

Testing Thermal Stability

PTFE is known for its exceptional heat resistance, but this must be verified.

Thermogravimetric Analysis (TGA) measures weight loss as a sample is heated, identifying the temperature at which the material begins to degrade. Dynamic Mechanical Analysis (DMA) assesses how properties like stiffness change with temperature.

Confirming Dimensional Accuracy

The part must conform to the design blueprint to ensure proper fit and function within an assembly.

A Coordinate Measuring Machine (CMM) uses a probe to take precise geometric measurements. Surface roughness testing evaluates the texture of the part's surface, which is critical for sealing and low-friction applications.

Common Pitfalls of Inadequate QC

Skipping or improperly conducting these tests can lead to catastrophic and often invisible product failures.

The Risk of Porosity

A part with low density is porous. This dramatically weakens the component and creates pathways for chemicals to permeate, defeating PTFE's primary benefit of chemical inertness.

The Problem of Incomplete Sintering

If the PTFE particles are not fully fused, the material will have poor tensile strength and can delaminate under stress or thermal cycling. The part may look fine but will fail prematurely in service.

The Consequence of Dimensional Errors

A seal that is even slightly out of tolerance will fail to create a proper seal. A bearing with an incorrect surface finish will wear out rapidly. These failures often cause damage to the larger assembly.

How to Apply This to Your Project

The specific QC regimen should be tailored to the demands of your component's end-use application.

- If your primary focus is high-pressure sealing: Prioritize density testing and precise dimensional inspection with a CMM.

- If your primary focus is dynamic components like bearings: Emphasize mechanical wear testing and surface roughness measurements.

- If your primary focus is high-temperature or critical chemical service: Mandate thermal stability analysis (TGA) and microstructure analysis (SEM).

Ultimately, rigorous quality control is the only way to guarantee that a PTFE component will deliver the exceptional performance the material is known for.

Summary Table:

| QC Category | Key Test Methods | Critical for Applications |

|---|---|---|

| Density & Microstructure | Archimedes' Principle, SEM/EDS | Chemical seals, ensuring material uniformity |

| Mechanical Performance | Tensile Testing, Wear Testing | Dynamic components (bearings, seals) under stress |

| Thermal Stability | TGA, DMA | High-temperature service, critical chemical environments |

| Dimensional Accuracy | CMM, Surface Roughness Testing | Precision sealing, proper fit and function in assemblies |

Need PTFE components that are guaranteed to perform?

At KINTEK, we manufacture high-precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our rigorous quality control process, including the methods detailed above, is integral to our manufacturing. We ensure every part—from prototypes to high-volume orders—meets the highest standards for density, strength, and dimensional accuracy, guaranteeing reliability in your most critical applications.

Contact KINTEK today to discuss your project requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers