In the food and beverage industry, Polytetrafluoroethylene (PTFE) is used for far more than just cookware. Its primary applications are non-stick and protective coatings for processing equipment, chemically inert linings for containers, and high-performance seals and gaskets that ensure product purity and operational efficiency. These uses stem from its unique combination of properties that solve critical challenges in food safety and manufacturing.

The core reason PTFE is essential to the food industry is not just its non-stick quality, but its profound chemical inertness and temperature resistance. This combination ensures that it can safely contact food products without causing contamination, even under the harsh conditions of industrial processing.

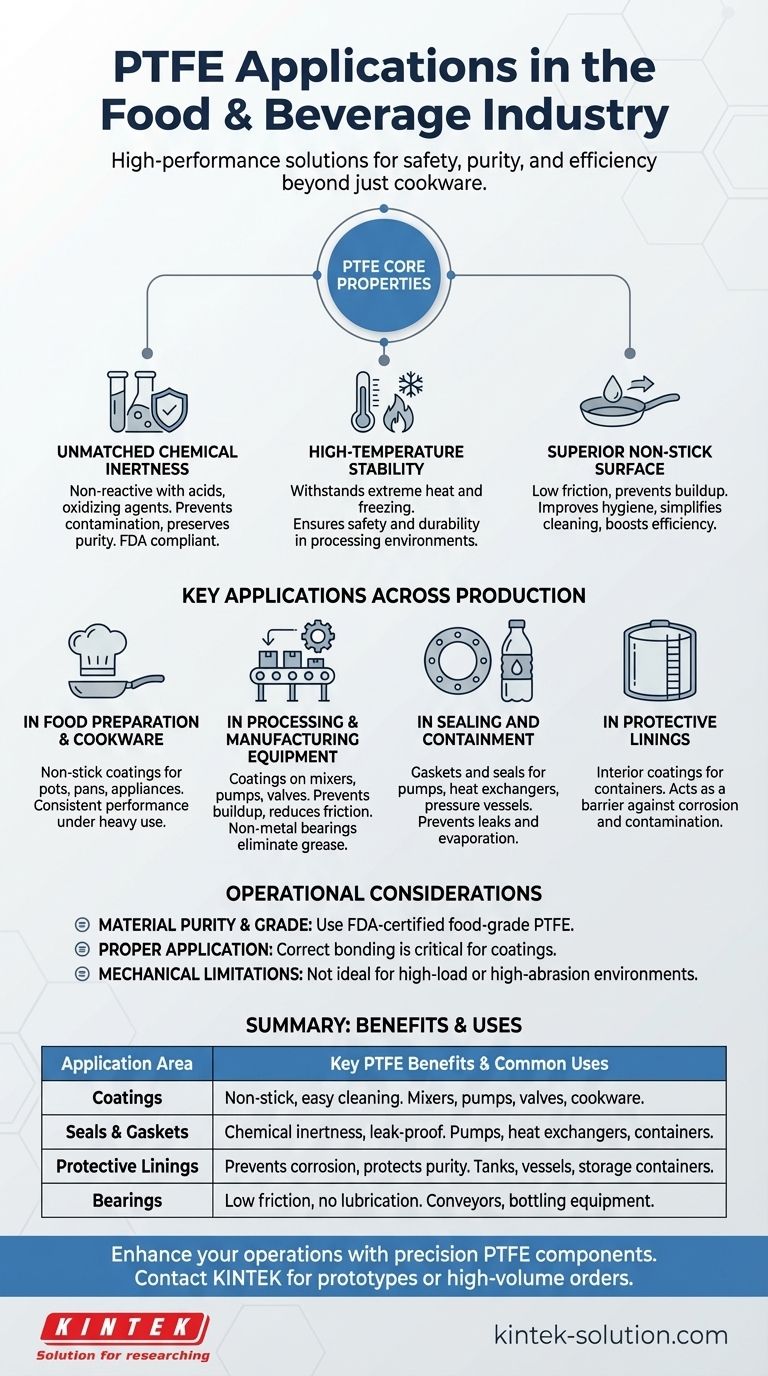

The Core Properties Driving Adoption

To understand PTFE's applications, we must first understand the fundamental material properties that make it so valuable in a food-grade context. These characteristics directly address the industry's highest priorities: safety, purity, and efficiency.

Unmatched Chemical Inertness

PTFE is one of the most non-reactive materials known. It does not react with acidic ingredients, oxidizing agents, or corrosive chemicals often found in food and cleaning products.

This inertness is crucial for preventing contamination and preserving the original taste and purity of the product. Because of this, PTFE components consistently meet strict FDA standards for food contact materials.

High-Temperature Stability

The material can withstand a wide range of temperatures, making it ideal for applications involving both cooking and freezing.

This high heat resistance ensures the PTFE coating or component remains stable and does not degrade during processing, which is critical for both safety and durability in demanding production environments.

Superior Non-Stick Surface

Famously known as a non-stick coating, PTFE's low coefficient of friction prevents food particles, grease, and other deposits from adhering to surfaces.

This property is vital for maintaining hygiene and improving operational efficiency. Equipment with PTFE coatings is easier to clean and helps prevent buildup that can slow down production or harbor bacteria.

Key Applications Across the Production Line

PTFE's properties translate into practical solutions at nearly every stage of food and beverage production, from initial processing to final packaging.

In Food Preparation & Cookware

The most recognized application is in non-stick coatings for commercial and consumer pots, pans, and other kitchen appliances. Its durability and heat resistance allow for consistent performance under heavy use.

In Processing & Manufacturing Equipment

PTFE is used to coat surfaces on mixers, pumps, valves, and bottling equipment. This prevents product buildup, reduces friction on moving parts, and simplifies cleaning protocols.

It is also used in non-metal bearings that do not require grease, eliminating a potential source of contamination while providing long service life.

In Sealing and Containment

As a material for gaskets and seals, PTFE is exceptionally effective. It is used in pumps, heat exchangers, and pressure vessels to create a tight, leak-proof seal that is non-reactive with the product.

For beverage containers, PTFE seals prevent leaks and evaporation during storage and transport, protecting the integrity of the final product.

In Protective Linings

PTFE is applied as a coating to the interior of food and beverage containers. This lining acts as a barrier, protecting the container from corrosion and, more importantly, protecting the product from contamination from the container itself.

Understanding the Operational Considerations

While highly effective, selecting and implementing PTFE requires an understanding of its context. It is a high-performance polymer, and its success depends on choosing the right type and application method for the job.

Material Purity and Grade

Not all PTFE is suitable for the food industry. It is essential to use food-grade PTFE that is certified to meet FDA or other relevant regulatory standards. This ensures no harmful additives or impurities are present.

Proper Application

For coatings, the bonding process to the substrate (like a metal pan or valve) is critical to its longevity and performance. An improperly applied coating can fail prematurely.

Mechanical Limitations

PTFE is a relatively soft material. While durable in its intended applications, it is not ideal for high-load or high-abrasion environments where it might be subject to physical wear and tear without proper engineering design.

Making the Right Choice for Your Application

Your primary goal will determine which of PTFE's benefits is most critical for your specific application.

- If your primary focus is product purity and safety: Leverage PTFE's chemical inertness and FDA compliance for direct-contact applications like container linings, gaskets, and seals.

- If your primary focus is operational efficiency: Apply PTFE coatings to processing equipment to prevent buildup, reduce cleaning time, and use its low-friction properties in non-lubricated bearings.

- If your primary focus is consumer product performance: Utilize its non-stick and high-heat properties for durable, easy-to-clean cookware and kitchen appliances.

Ultimately, integrating PTFE into food and beverage applications is a strategic decision to enhance safety, efficiency, and product integrity from the processing line to the final package.

Summary Table:

| Application Area | Key PTFE Benefits | Common Uses |

|---|---|---|

| Coatings | Non-stick, easy cleaning, heat resistance | Mixers, pumps, valves, cookware |

| Seals & Gaskets | Chemical inertness, leak-proof, FDA compliant | Pumps, heat exchangers, containers |

| Protective Linings | Prevents corrosion, protects product purity | Tanks, vessels, storage containers |

| Bearings | Low friction, no lubrication needed | Conveyors, bottling equipment |

Ready to enhance your food and beverage operations with high-performance PTFE components?

KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. We ensure every part meets stringent FDA standards for safety and purity.

Whether you need prototypes or high-volume orders, our custom fabrication expertise delivers solutions that boost efficiency and protect product integrity.

Contact us today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability