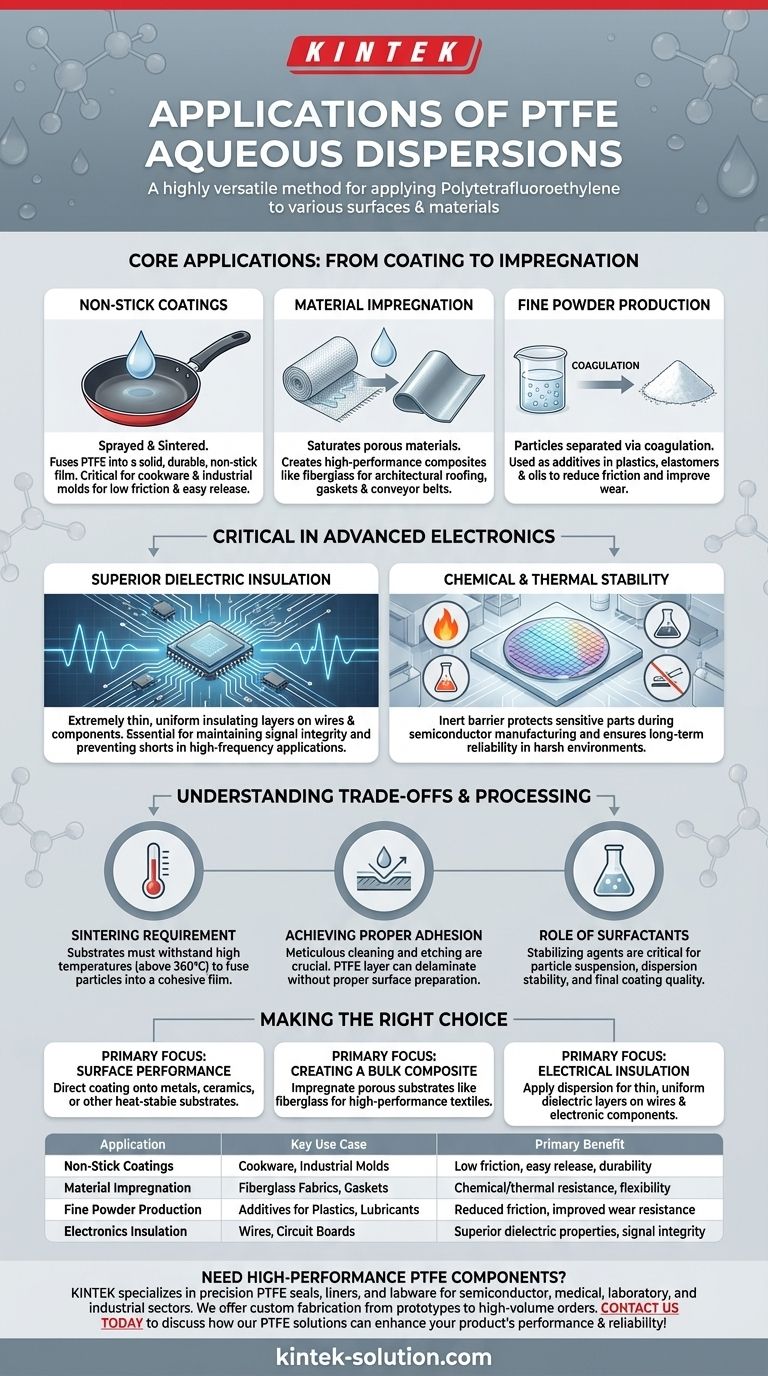

In essence, PTFE aqueous dispersions are a highly versatile method for applying Polytetrafluoroethylene to various surfaces and materials. Their primary applications are creating high-performance non-stick coatings, impregnating porous materials like fabrics to create composites, and producing fine powders used as additives.

The core challenge with PTFE is applying a famously inert and solid material onto other substrates. Aqueous dispersions solve this by suspending microscopic PTFE particles in water, allowing this powerful polymer to be sprayed, dipped, or soaked into other materials, thereby transferring its exceptional properties.

Core Applications: From Coating to Impregnation

The liquid form of a PTFE dispersion is what makes it so useful. It allows for application methods that would be impossible with solid PTFE resin, unlocking a wide range of industrial and commercial uses.

Non-Stick Coatings

This is the most well-known application. The dispersion is applied to a substrate, often by spraying, and then heated in a process called sintering.

This process evaporates the water and fuses the PTFE particles into a solid, durable, non-stick film. These coatings are critical for cookware, industrial molds, and any surface requiring low friction and easy release.

Material Impregnation

Porous materials can be saturated with a PTFE dispersion to create high-performance composites.

Fiberglass fabric, for example, is often impregnated with PTFE. After heating, the result is a material that is flexible, extremely resistant to chemicals and high temperatures, and possesses excellent dielectric properties. These composites are used in architectural roofing, industrial gaskets, and conveyor belts.

Production of Fine Powders

The PTFE particles can be separated from the water in the dispersion through a process called coagulation.

This creates a fine powder that serves as a valuable additive. These powders are blended into other materials, such as plastics, elastomers, and lubricating oils, to reduce their coefficient of friction and improve wear resistance.

Why Dispersions are Critical in Advanced Electronics

PTFE's inherent properties make it invaluable in the electronics and semiconductor industries. The dispersion form is the key to applying these properties with the precision required for micro-components.

Superior Dielectric Insulation

PTFE is one of the best electrical insulators known. A dispersion allows for the application of an extremely thin, uniform insulating layer on wires, cables, and circuit board components.

This is critical for maintaining signal integrity and preventing electrical shorts in high-frequency applications where performance cannot be compromised.

Chemical and Thermal Stability

Semiconductor manufacturing involves exposing components to highly corrosive chemicals and extreme temperatures.

PTFE coatings, applied via dispersion, create a completely inert barrier. This protects sensitive electronic parts during fabrication and ensures their long-term reliability in harsh operating environments.

Understanding the Trade-offs and Processing

While powerful, working with PTFE dispersions involves specific technical considerations that are critical for success. Understanding these limitations is key to a successful application.

The Sintering Requirement

The applied liquid coating has none of PTFE's final properties until it is properly heated. The substrate must be able to withstand the high temperatures required for sintering (typically above 360°C or 680°F) to fuse the particles into a cohesive film.

Achieving Proper Adhesion

By its very nature, PTFE does not stick to things. To ensure a durable coating, the underlying substrate must be meticulously cleaned and often chemically etched or primed. Without proper surface preparation, the PTFE layer can delaminate.

The Role of Surfactants

Dispersions require stabilizing agents, or surfactants, to keep the PTFE particles evenly suspended in the water. The selection and management of these surfactants are critical to the stability of the dispersion and the quality of the final coating.

Making the Right Choice for Your Goal

The method of application is determined entirely by the desired outcome. Your end goal dictates whether you are creating a surface layer, a composite material, or an additive.

- If your primary focus is surface performance (non-stick, low friction): Your best approach is using the dispersion for direct coating onto metals, ceramics, or other heat-stable substrates.

- If your primary focus is creating a bulk composite material: Use the dispersion to impregnate porous substrates like fiberglass or other woven fabrics to create high-performance textiles.

- If your primary focus is electrical insulation: Apply the dispersion to create thin, uniform dielectric layers on wires and electronic components where thermal and chemical resistance are critical.

By understanding the dispersion method, you can effectively transfer PTFE's exceptional characteristics to a vast range of substrates and components.

Summary Table:

| Application | Key Use Case | Primary Benefit |

|---|---|---|

| Non-Stick Coatings | Cookware, industrial molds | Low friction, easy release, durability |

| Material Impregnation | Fiberglass fabrics, gaskets | Chemical/thermal resistance, flexibility |

| Fine Powder Production | Additives for plastics, lubricants | Reduced friction, improved wear resistance |

| Electronics Insulation | Wires, circuit boards | Superior dielectric properties, signal integrity |

Need high-performance PTFE components for your application? KINTEK specializes in manufacturing precision PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders to meet your exact requirements. Contact us today to discuss how our PTFE solutions can enhance your product's performance and reliability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support