For high-duty cycle linear actuators, PTFE piston seals offer a superior combination of low friction, long service life, and cost-effectiveness. Their primary advantage is the ability to virtually eliminate "stick-slip" behavior—the jerky motion common with other seal types—which ensures smooth, predictable performance over millions of cycles.

The core challenge in a high-duty cycle system is not just sealing, but maintaining consistent performance and efficiency under relentless operation. While other seals may work initially, PTFE's fundamentally low-friction nature directly translates into reduced wear, lower heat generation, and superior long-term reliability.

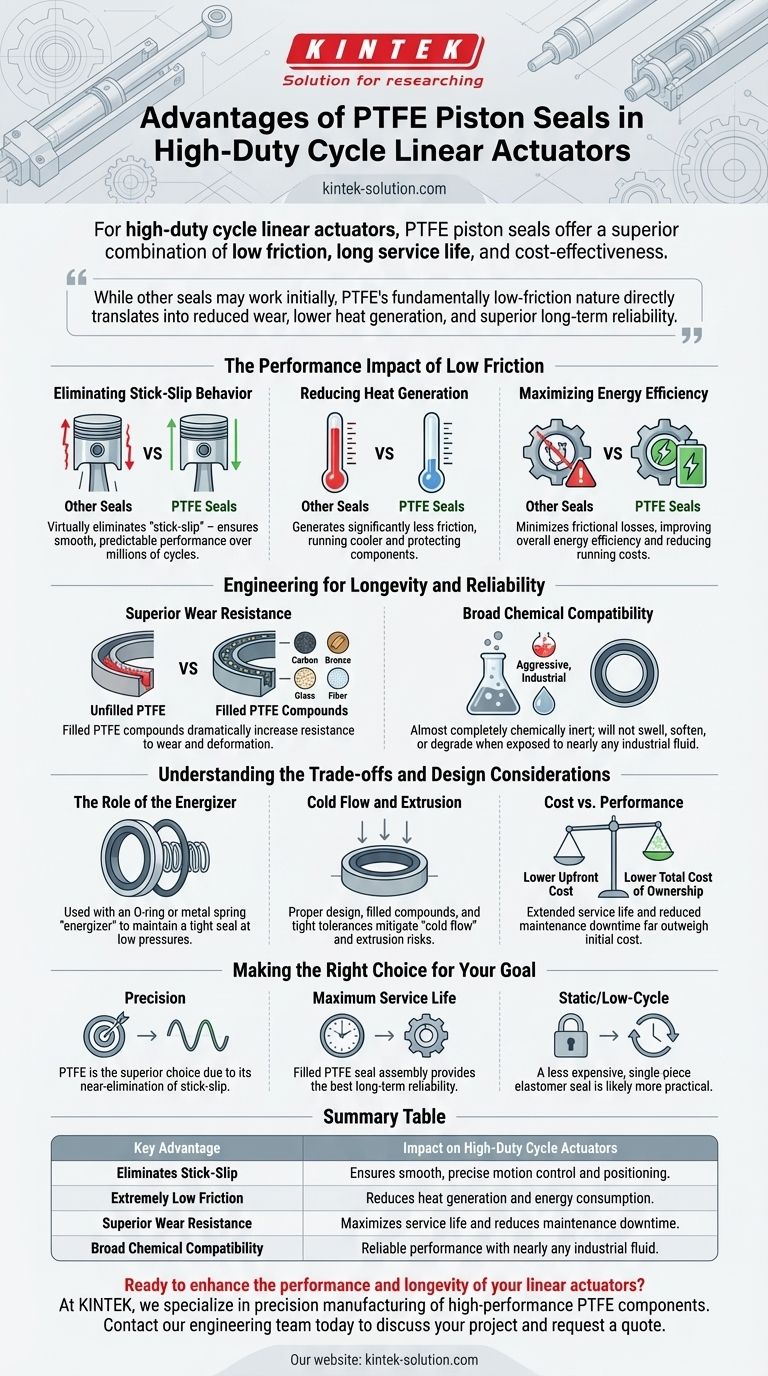

The Performance Impact of Low Friction

The defining characteristic of Polytetrafluoroethylene (PTFE) is its extremely low coefficient of friction, one of the lowest of any solid material. This property is the foundation for its advantages in dynamic sealing applications.

Eliminating Stick-Slip Behavior

Stick-slip occurs when the static friction (the force needed to start movement) is significantly higher than the dynamic friction (the force needed to keep it moving). This causes a "jump" at the start of each stroke.

In high-repetition tasks, this leads to imprecise positioning and increased mechanical shock. PTFE's minimal difference between static and dynamic friction ensures a smooth transition from stop to start, which is critical for consistent and precise actuator control.

Reducing Heat Generation

Friction generates heat. In a high-duty cycle actuator running constantly, this heat accumulates, which can degrade hydraulic fluid, accelerate seal aging, and affect the performance of the entire system.

Because PTFE seals generate significantly less friction, they run cooler. This thermal stability protects the seal and surrounding components, directly contributing to a longer operational life and more predictable performance.

Maximizing Energy Efficiency

Every bit of energy used to overcome friction is wasted. While negligible in a single cycle, this waste becomes a significant operational cost over millions of strokes.

By minimizing frictional losses, PTFE seals improve the overall energy efficiency of the hydraulic or pneumatic system, reducing long-term running costs.

Engineering for Longevity and Reliability

A seal in a high-cycle environment is a point of constant wear. The design and material properties of a PTFE seal are optimized for durability in these conditions.

Superior Wear Resistance

While pure PTFE is a relatively soft material, piston seals are typically made from filled PTFE compounds. Fillers such as carbon, bronze, or glass fiber are added to the material matrix.

These fillers dramatically increase the seal's resistance to wear and deformation, allowing it to withstand high pressure and constant movement without rapid degradation.

Broad Chemical Compatibility

Hydraulic systems can use a wide range of fluids, some of which can be aggressive toward conventional elastomer (rubber) seals.

PTFE is almost completely chemically inert. It will not swell, soften, or degrade when exposed to nearly any industrial fluid, ensuring its physical properties and sealing ability remain intact over its entire service life.

Understanding the Trade-offs and Design Considerations

No material is perfect for every situation. Understanding the design context for PTFE seals is key to leveraging their strengths.

The Role of the Energizer

PTFE is not an elastomer; it has very little "memory" or elasticity. On its own, it cannot provide the constant radial force needed to maintain a tight seal, especially at low pressures.

For this reason, PTFE piston seals are almost always used with an O-ring or metal spring "energizer." This separate component sits behind the PTFE jacket and provides the constant outward force needed to keep the seal lip engaged with the cylinder bore.

Cold Flow and Extrusion

Under sustained pressure and temperature, PTFE can be prone to "cold flow" or creep, where the material slowly deforms. It is also more susceptible to extruding into the clearance gap between the piston and cylinder wall compared to harder materials.

Proper design, including the use of filled PTFE compounds and tight machining tolerances, mitigates these risks. Anti-extrusion or back-up rings are often incorporated in high-pressure designs.

Cost vs. Performance

While the references note PTFE seals are "relatively low cost," this is in the context of high-performance components. A standard nitrile or urethane seal will have a lower upfront piece price.

The value proposition for PTFE is a lower total cost of ownership. The extended service life and reduced maintenance downtime in demanding applications far outweigh the initial component cost.

Making the Right Choice for Your Goal

To select the correct seal, you must align the material's properties with your primary engineering objective.

- If your primary focus is precision and smooth control: PTFE is the superior choice due to its near-elimination of stick-slip.

- If your primary focus is maximum service life in a high-repetition system: The low-wear, low-friction characteristics of a filled PTFE seal assembly provide the best long-term reliability.

- If your primary focus is static sealing or a low-cycle, low-performance application: A less expensive, single-piece elastomer seal is likely a more practical choice.

Ultimately, choosing the right seal requires understanding that its material properties directly shape the long-term performance and reliability of your entire system.

Summary Table:

| Key Advantage | Impact on High-Duty Cycle Actuators |

|---|---|

| Eliminates Stick-Slip | Ensures smooth, precise motion control and positioning. |

| Extremely Low Friction | Reduces heat generation and energy consumption. |

| Superior Wear Resistance | Maximizes service life and reduces maintenance downtime. |

| Broad Chemical Compatibility | Reliable performance with nearly any industrial fluid. |

Ready to enhance the performance and longevity of your linear actuators?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom piston seals for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a seal solution optimized for your specific requirements, delivering lower total cost of ownership through superior reliability.

Contact our engineering team today to discuss your project and request a quote.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are the key steps for properly installing PTFE seals? Ensure a Leak-Free, Long-Lasting Seal

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance

- How do PTFE seals perform under pressurized conditions? Achieving Reliable Sealing in Demanding Environments