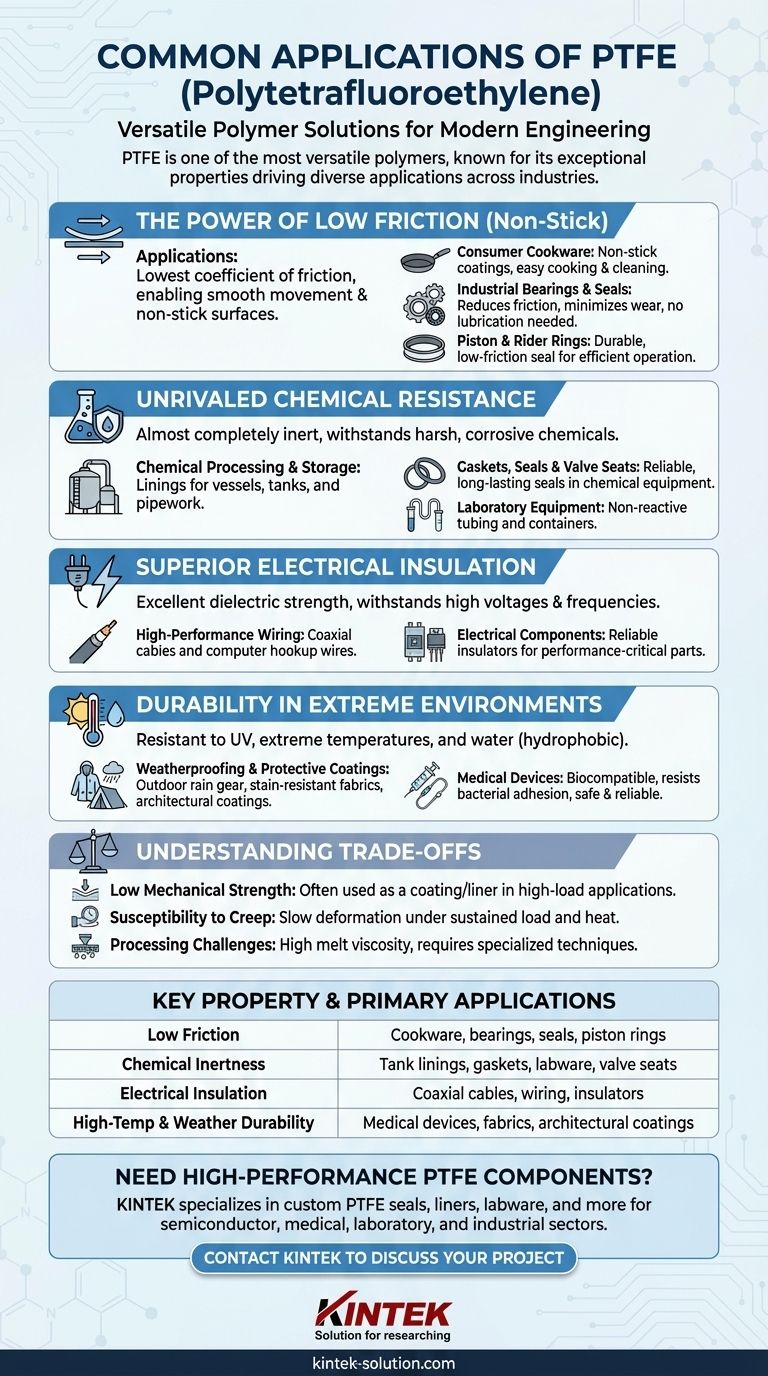

At its core, Polytetrafluoroethylene (PTFE) is one of the most versatile polymers in modern engineering. Its applications are incredibly diverse, ranging from non-stick coatings on cookware and weather-resistant fabrics to critical components in the medical, chemical, and electronics industries. Common uses include seals, gaskets, bearings, electrical wire insulation, and linings for pipes and tanks handling corrosive chemicals.

The wide array of PTFE applications is not random. Each use case is a direct result of one of its four defining properties: an extremely low coefficient of friction, exceptional chemical inertness, high-temperature stability, and excellent electrical insulation.

The Properties Driving the Applications

To truly understand where and why PTFE is used, it's best to connect its applications to its fundamental characteristics. Almost every use case is an exploitation of one or more of its remarkable properties.

1. The Power of Low Friction (Non-Stick)

PTFE has one of the lowest coefficients of friction of any known solid material, giving it an iconic "slipperiness." This property is essential for applications where smooth movement and a non-stick surface are critical.

Consumer Cookware

This is the most famous application of PTFE. As a coating on pots and pans, it prevents food from sticking, simplifying both cooking and cleaning.

Industrial Bearings and Seals

In machinery, PTFE is used for bearings, bushings, gears, and slide plates. These components reduce friction between moving parts, which minimizes wear, lowers energy consumption, and eliminates the need for liquid lubricants in some cases.

Piston and Rider Rings

Within compressors, piston rings and rider rings made of PTFE provide a durable, low-friction seal, ensuring efficient operation and a long service life.

2. Unrivaled Chemical Resistance

PTFE is almost completely inert, meaning it does not react with the vast majority of corrosive and reactive chemicals. This makes it an indispensable material in harsh chemical environments.

Chemical Processing and Storage

The material is used to line vessels, chemical tanks, and pipework. This protects the structural material (often steel) from aggressive contents and prevents contamination of the chemical itself.

Gaskets, Seals, and Valve Seats

Because it doesn't degrade when exposed to harsh chemicals, PTFE is a top choice for gaskets, O-rings, and valve seats. It creates a reliable and long-lasting seal in chemical processing equipment.

Laboratory Equipment

Due to its non-reactive nature and easy-to-clean surface, PTFE is used for chemical tubing and containers in laboratory settings.

3. Superior Electrical Insulation

PTFE is an excellent electrical insulator with a very high dielectric strength, meaning it can withstand high voltages without breaking down. It also maintains these properties across a wide range of frequencies.

High-Performance Wiring

It is a preferred insulator for coaxial cables and computer hookup wires, especially in applications where signal integrity is paramount, such as in aerospace and defense systems.

Electrical Components

Its insulating properties make it a reliable material for various electrical insulators and components where performance cannot be compromised.

4. Durability in Extreme Environments

PTFE is both hydrophobic (water-repellent) and highly resistant to UV radiation and extreme temperatures, making it exceptionally durable in challenging conditions.

Weatherproofing and Protective Coatings

PTFE is used in high-performance outdoor rain gear and stain-resistant fabrics. It's also used in architectural applications as a protective coating for the roofs of stadiums and airports, offering long-term weather protection.

Medical Devices

The material is biocompatible and resists bacterial adhesion. This makes it ideal for medical applications like catheters, syringes, sutures, and vascular grafts, where safety and reliability are non-negotiable.

Understanding the Trade-offs

While incredibly useful, PTFE is not the perfect material for every situation. Its limitations are as important to understand as its strengths.

Low Mechanical Strength

Compared to metals or other engineering plastics, PTFE is relatively soft and has lower tensile strength. For high-load structural applications, it is often used as a coating or liner rather than the primary component.

Susceptibility to Creep

Under a sustained load, especially at elevated temperatures, PTFE can slowly deform over time. This phenomenon, known as "creep," must be accounted for in the design of critical components like seals and bearings.

Processing Challenges

PTFE has an extremely high melt viscosity, which means it doesn't flow like common plastics when heated. This makes it unsuitable for traditional injection molding and requires specialized processing techniques.

Making the Right Choice for Your Goal

Selecting a material depends entirely on the problem you need to solve. PTFE is often the definitive choice when performance under specific conditions is the primary driver.

- If your primary focus is reducing friction or creating a non-stick surface: PTFE is the industry standard for applications from industrial bearings to consumer cookware.

- If your primary focus is handling corrosive or reactive chemicals: PTFE's profound chemical inertness makes it the ideal choice for linings, seals, and tubing.

- If your primary focus is high-frequency electrical insulation: PTFE's superior dielectric properties are essential for performance in critical cables and electronic components.

- If your primary focus is durability in harsh environments: PTFE's resistance to weather, chemicals, and temperature makes it a reliable choice for everything from architectural fabrics to medical devices.

Understanding these core principles reveals that PTFE is far more than just a coating for pans; it is a cornerstone material of modern engineering.

Summary Table:

| Key Property | Primary Applications |

|---|---|

| Low Friction (Non-Stick) | Cookware coatings, bearings, seals, piston rings |

| Chemical Inertness | Chemical tank linings, gaskets, labware, valve seats |

| Electrical Insulation | Coaxial cables, high-performance wiring, insulators |

| High-Temp & Weather Durability | Medical devices, protective fabrics, architectural coatings |

Need High-Performance PTFE Components?

KINTEK specializes in the precision manufacturing of custom PTFE components—including seals, liners, labware, and more—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures your application benefits from PTFE's superior properties.

Contact KINTEK today to discuss your project requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability