At their core, PTFE bushes are high-performance bearings made from Polytetrafluoroethylene, a synthetic polymer best known by the brand name Teflon. These cylindrical sleeves are engineered to reduce friction, support movement, and absorb shock between moving parts, particularly in harsh environments where traditional lubricated metal bearings would fail. They are commonly used in industrial machinery, chemical processing equipment, and electrical systems.

The true value of a PTFE bush isn't just that it's a plastic sleeve, but that it's a self-lubricating, chemically inert component. It solves the problem of motion in environments too corrosive, too hot, or too difficult to lubricate for conventional materials.

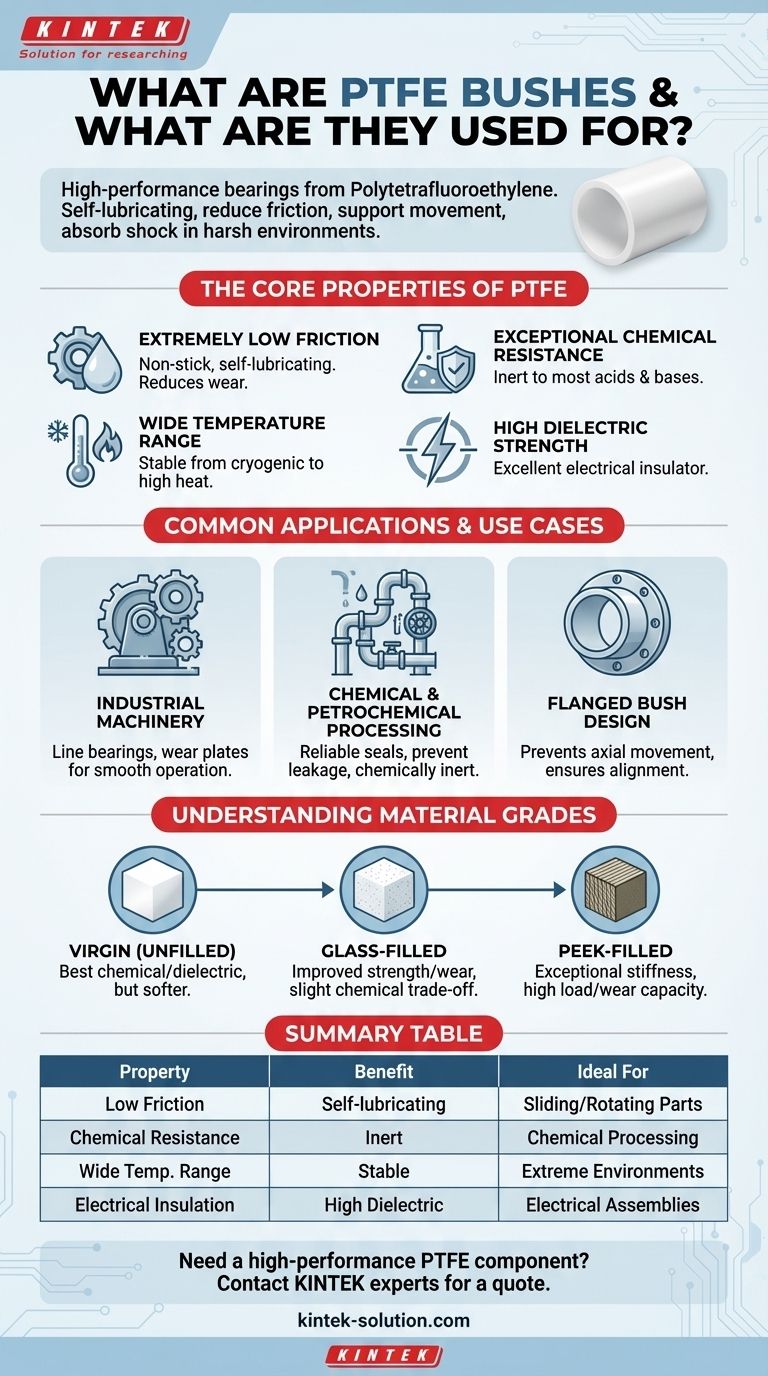

The Core Properties of PTFE

To understand why these components are so effective, you must first understand the fundamental properties of the material itself. PTFE is not chosen by accident; it is specified for its unique combination of characteristics.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This gives it a naturally non-stick and self-lubricating quality.

This property is critical for applications with sliding or rotating parts, as it drastically reduces wear and energy consumption without requiring external oils or greases.

Exceptional Chemical Resistance

The carbon-fluorine bonds in PTFE are incredibly strong, making the material almost completely inert to most chemicals, including aggressive acids and bases.

This makes PTFE bushes essential for use in pumps, valves, and seals within the chemical processing and oil & gas industries, where components are constantly exposed to corrosive substances.

Wide Temperature Range

PTFE maintains its properties across a broad spectrum of temperatures. It can operate effectively in cryogenic conditions as well as elevated heat, providing stable performance where other polymers would become brittle or melt.

High Dielectric Strength

PTFE is an excellent electrical insulator, meaning it does not conduct electricity. This property makes it a valuable material for insulating parts and components within electrical and electronic assemblies.

Common Applications and Use Cases

The unique properties of PTFE directly translate to its use in demanding industrial settings where performance and reliability are non-negotiable.

Industrial Machinery

PTFE bushes are frequently used as line bearings and wear plates in all types of machinery. They support linear or rotational movement, ensuring smooth, low-friction operation over long periods.

Chemical and Petrochemical Processing

In pumps, valves, and fluid handling systems, PTFE bushes and seals provide a reliable barrier against leakage. Their chemical inertness ensures they will not degrade or contaminate the process fluid.

Flanged Bush Design

Some PTFE bushes feature a flange at one end. This flange acts as a locating surface, preventing axial movement and ensuring precise alignment.

This design is common in linear motion systems and pumps where maintaining a component's position along a shaft is critical.

Understanding the Trade-offs and Material Grades

While "PTFE" is a useful term, the material is rarely used in a single form. Engineers select different grades based on the specific mechanical and environmental demands of the application.

Virgin (Unfilled) PTFE

This is the pure, unmodified polymer. It offers the highest chemical resistance and best dielectric properties. However, it is relatively soft and susceptible to "creep" – a slow deformation under sustained load.

Glass-Filled PTFE

By adding glass fibers to the PTFE matrix, the material's mechanical strength and wear resistance are significantly improved. This is one of the most common grades for bearings and seals.

The trade-off is a slight reduction in chemical resistance compared to virgin PTFE, as the glass fibers can be attacked by certain aggressive chemicals.

PEEK-Filled PTFE

For the most demanding applications, Polyetheretherketone (PEEK) is added as a filler. This creates a composite with exceptional stiffness, high load-bearing capacity, and excellent wear resistance, combining the best properties of both materials.

Making the Right Choice for Your Goal

Selecting the correct PTFE material is a matter of matching the grade to the primary challenge of your application.

- If your primary focus is chemical inertness or electrical insulation: Virgin PTFE provides the purest performance for these requirements.

- If your primary focus is mechanical strength and general wear resistance: Glass-filled PTFE offers a balanced, cost-effective upgrade for most industrial bearing applications.

- If your primary focus is performance under high loads and extreme wear: PEEK-filled PTFE is the superior choice for the most demanding mechanical duties.

Choosing the right material is the key to unlocking the full potential of PTFE's unique engineering advantages.

Summary Table:

| Property | Benefit | Ideal For |

|---|---|---|

| Low Friction | Self-lubricating, reduces wear | Sliding/rotating parts, machinery |

| Chemical Resistance | Inert to acids, bases, solvents | Chemical processing, oil & gas |

| Wide Temp. Range | Stable from cryogenic to high heat | Extreme environment applications |

| Electrical Insulation | High dielectric strength | Electrical assemblies, components |

Need a high-performance PTFE component for a demanding application?

At KINTEK, we specialize in the precision manufacturing of PTFE components, including seals, liners, labware, and custom bushes. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we can fabricate the perfect solution—from prototypes to high-volume orders—to meet your specific requirements for chemical resistance, low friction, and durability.

Contact our experts today to discuss your project and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments