Yes, Teflon is used in clothing and textiles, but not as a standalone fabric. Instead, a very thin coating of Teflon—technically a brand name for polytetrafluoroethylene (PTFE)—is applied as a finish to conventional fabrics. This invisible layer imparts valuable properties like water and stain resistance without changing the look or feel of the material.

The core principle to understand is that Teflon acts as a high-performance enhancement for textiles. It’s not the material clothing is made from, but a functional finish applied to the material to protect it from liquids and stains.

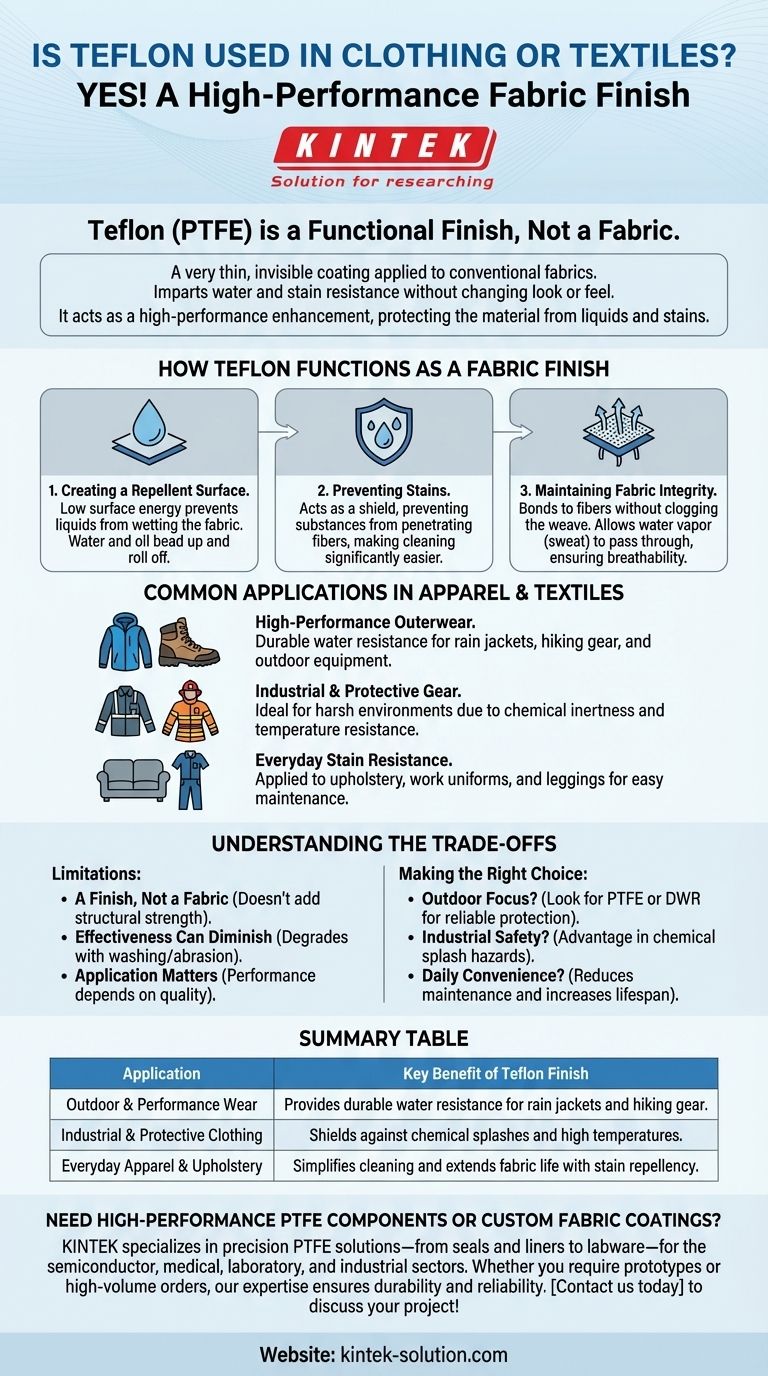

How Teflon Functions as a Fabric Finish

When applied to textiles, a Teflon finish creates a protective barrier around each fiber. This barrier fundamentally changes how the fabric interacts with external substances, particularly liquids.

Creating a Repellent Surface

The key property of Teflon is its extremely low coefficient of friction, which gives it a "nonstick" quality.

This low surface energy prevents liquids from wetting the fabric. Instead of soaking in, water, oil, and other potential stains bead up and roll right off.

Preventing Stains

For any liquid that doesn't immediately roll off, the Teflon coating acts as a shield, preventing the substance from penetrating and setting into the fabric's fibers.

This makes the clothing or textile significantly easier to clean, as stains are kept on the surface rather than becoming absorbed.

Maintaining Fabric Integrity

A properly applied Teflon finish bonds to the fibers without clogging the weave of the fabric.

This is critical because it allows the textile to remain breathable. Water vapor (like sweat) can still pass through, ensuring the garment remains comfortable to wear.

Common Applications in Apparel and Textiles

Teflon finishes are used where durability, cleanliness, and weather resistance are paramount. You will typically find it in specialized or high-impact clothing rather than everyday fashion.

High-Performance Outerwear

Due to its exceptional water resistance, Teflon is a common finish for waterproof clothing like rain jackets, hiking boots, and other outdoor gear. It provides a durable barrier against the elements.

Industrial and Protective Gear

The chemical inertness and temperature resistance of Teflon make it ideal for protective clothing.

It is frequently applied to industrial workwear, boilersuits, and even firefighter gear to protect the wearer in harsh environments.

Everyday Stain Resistance

While less common, some manufacturers apply a Teflon finish to items prone to spills and stains, such as work uniforms, leggings, and even upholstery fabric, to extend their life and simplify maintenance.

Understanding the Trade-offs

While a Teflon finish provides significant benefits, it's important to recognize its role and limitations as a coating.

It's a Finish, Not a Fabric

The coating enhances the properties of the base material (like cotton or polyester) but does not add structural strength. The overall durability of the garment still depends on the underlying fabric.

Effectiveness Can Diminish

As a surface treatment, the Teflon finish can degrade over time. Repeated washing, abrasion, and exposure to harsh detergents can slowly wear the coating away, reducing its water- and stain-repellent capabilities.

Application Matters

The performance of the finish is highly dependent on the quality of its application during manufacturing. An uneven or poorly bonded coating will not deliver the expected level of protection and may wear off quickly.

Making the Right Choice for Your Goal

Understanding when a Teflon finish is beneficial helps you select the right product for your needs.

- If your primary focus is outdoor performance and weather protection: Look for outerwear and gear that explicitly mentions a PTFE or similar durable water-repellent (DWR) finish for reliable protection.

- If your primary focus is industrial safety: Garments with a Teflon finish offer a distinct advantage in environments with chemical or liquid splash hazards.

- If your primary focus is daily convenience and easy cleaning: A Teflon finish on workwear or home goods can significantly reduce maintenance and increase the item's lifespan.

Ultimately, a Teflon finish is a specialized tool used to elevate the performance of a textile for a specific purpose.

Summary Table:

| Application | Key Benefit of Teflon Finish |

|---|---|

| Outdoor & Performance Wear | Provides durable water resistance for rain jackets and hiking gear. |

| Industrial & Protective Clothing | Shields against chemical splashes and high temperatures. |

| Everyday Apparel & Upholstery | Simplifies cleaning and extends fabric life with stain repellency. |

Need high-performance PTFE components or custom fabric coatings? KINTEK specializes in precision PTFE solutions—from seals and liners to labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures durability and reliability. Contact us today to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs