When evaluating shovel materials, PTFE (Polytetrafluoroethylene) is significantly more durable than a standard plastic shovel. This superiority is not just a minor improvement; it stems from the fundamental chemical and physical properties of PTFE, which provide a much longer service life and greater resistance to environmental degradation and physical wear.

A PTFE shovel's durability goes beyond simply resisting breakage. Its true value lies in a combination of exceptional weather and temperature resilience, chemical stability, and a unique low-friction surface that improves performance and reduces wear over time.

What Makes PTFE a More Durable Material?

The term "durability" encompasses several key characteristics where PTFE excels compared to common plastics like polypropylene or high-density polyethylene (HDPE) often used in shovels.

Inherent Chemical Stability

PTFE is virtually immune to weathering. It actively resists damage from UV light, oxidation, and embrittlement caused by environmental exposure.

Unlike standard plastics that can fade, crack, or become brittle after prolonged time outdoors, PTFE maintains its structural integrity and color.

Extreme Temperature Tolerance

A critical failure point for plastic shovels is cold-induced brittleness. PTFE operates effectively in an exceptionally wide temperature range, from -250°C to +250°C (-418°F to +482°F).

This means it will not become fragile or crack even in the most extreme winter conditions, a common fate for less robust plastic tools.

Resistance to Wear and Tear

The inherent toughness of PTFE means it stands up better to the repeated scraping and impact that a shovel endures.

This leads directly to a longer service life, reducing the need for frequent replacements and making it a more cost-effective choice over the long term.

Beyond Breakage: The Performance Advantage of PTFE

Durability isn't just about how long a tool lasts; it's also about how well it performs during its lifespan. PTFE's unique surface properties give it a distinct advantage.

An Exceptionally Low-Friction Surface

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. Its static and kinetic friction values (around 0.04) are significantly lower than other polymers like Nylon or plastics.

For a shovel, this means materials like wet snow, sticky soil, or mulch slide off effortlessly. This non-stick quality prevents frustrating buildup and makes each load easier to manage.

Reduced Physical Strain

Because material does not stick to the blade, the user exerts less effort to clear the shovel after each scoop.

This efficiency reduces physical strain and fatigue, allowing work to be completed more quickly and comfortably. The tool, in effect, does more of the work.

Understanding the Trade-offs

While PTFE offers superior durability and performance, it's essential to consider the full picture to make an informed decision.

The Primary Consideration: Cost

PTFE is a high-performance polymer, and its manufacturing process is more complex than that of common plastics. This is typically reflected in a higher initial purchase price.

However, its extended lifespan can offset this initial investment by reducing the long-term cost of replacement.

"Durable" Is Not "Indestructible"

While highly resistant to wear and abrasion, a PTFE shovel is not immune to damage. A sharp, high-velocity impact against a hard edge like concrete or sharp rock can still cause a chip or gouge.

It will vastly outperform standard plastic in these scenarios but should still be used with the care appropriate for any high-quality tool.

Making the Right Choice for Your Needs

Selecting the right shovel means aligning the material's properties with the demands of your task and environment.

- If your primary focus is long-term value and performance in harsh conditions: The investment in a PTFE shovel is justified by its superior lifespan, non-stick surface, and resilience in extreme cold.

- If your primary focus is occasional, light-duty use on a strict budget: A standard plastic shovel can be a sufficient, low-cost option, but expect a shorter service life and more effort when dealing with sticky materials.

Ultimately, choosing the right material is about matching the tool's capabilities to the demands of your work.

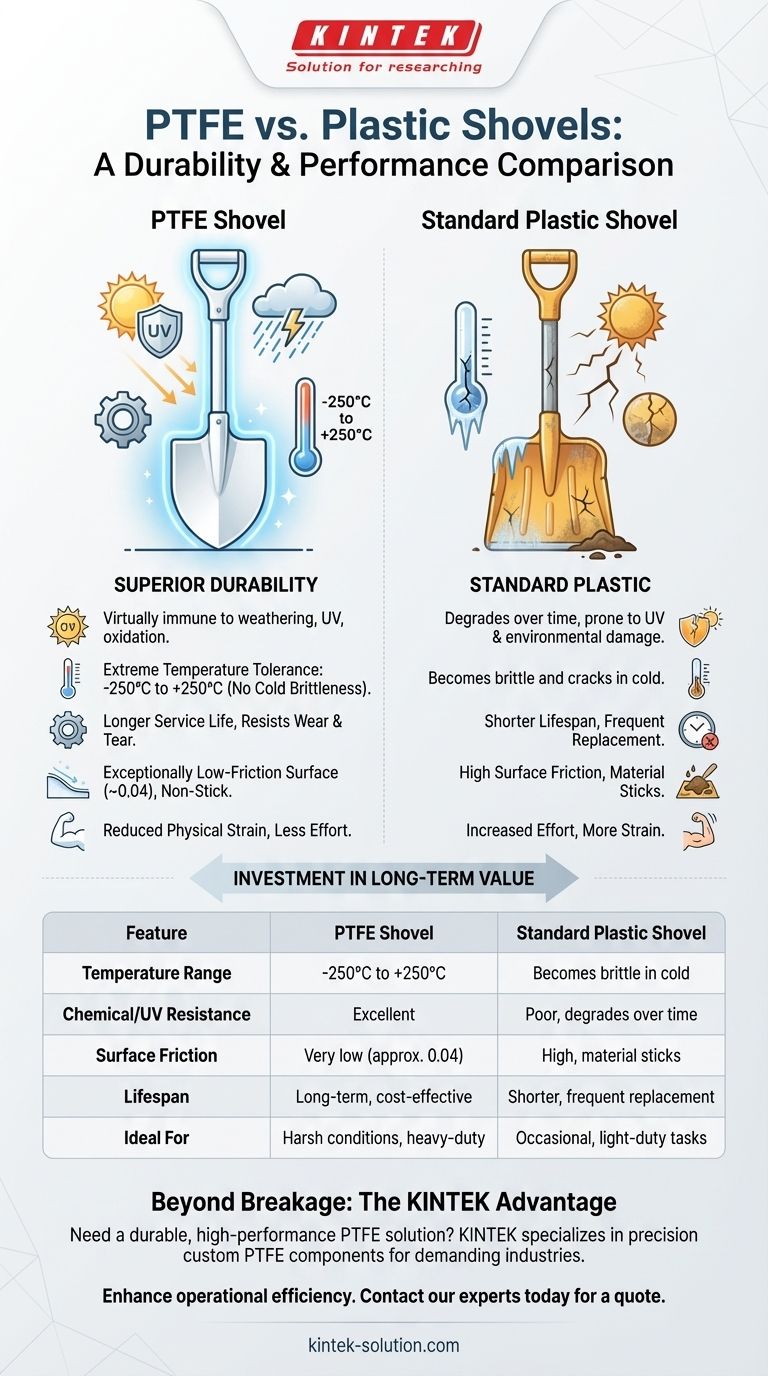

Summary Table:

| Feature | PTFE Shovel | Standard Plastic Shovel |

|---|---|---|

| Temperature Range | -250°C to +250°C | Becomes brittle in cold |

| Chemical/UV Resistance | Excellent | Poor, degrades over time |

| Surface Friction | Very low (approx. 0.04) | High, material sticks |

| Lifespan | Long-term, cost-effective over time | Shorter, frequent replacement |

| Ideal For | Harsh conditions, heavy-duty use | Occasional, light-duty tasks |

Need a durable, high-performance PTFE solution for your specific application?

At KINTEK, we don't just sell PTFE shovels; we specialize in precision manufacturing of custom PTFE components for the most demanding industries, including semiconductor, medical, and laboratory applications. Our expertise ensures you get a product tailored to your exact requirements, from prototypes to high-volume orders.

Let us help you enhance your operational efficiency and durability. Contact our experts today to discuss your project and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Customizable PTFE Scrapers and Shovels for Demanding Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments