In chemically aggressive environments, PTFE's performance is defined by its exceptional inertness. It is one of the most chemically resistant polymers available, remaining stable and non-reactive when exposed to a vast range of acids, bases, solvents, and corrosive industrial fluids. This reliability makes it a primary material for demanding applications in chemical processing, automotive, and aerospace industries.

The fundamental reason for PTFE's superior performance is its molecular structure, which makes it non-reactive to nearly all chemicals. This inherent chemical stability ensures it will not degrade, swell, or corrode, guaranteeing long-term integrity and safety in harsh operational settings.

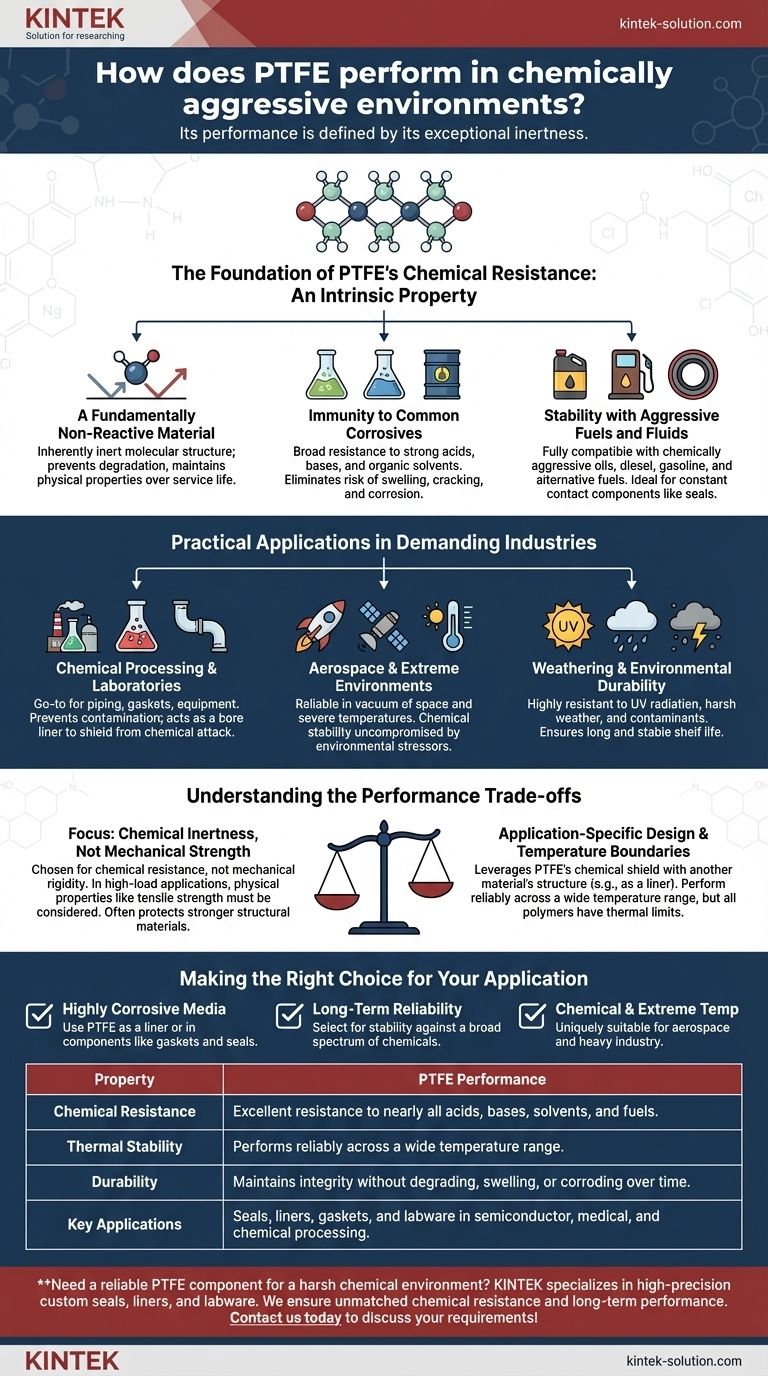

The Foundation of PTFE's Chemical Resistance

Polytetrafluoroethylene (PTFE) is engineered for chemical stability. Its performance is not a feature that is added, but rather an intrinsic property of the material itself, making it a predictable and reliable choice for critical applications.

A Fundamentally Non-Reactive Material

At a molecular level, PTFE is inherently inert. Its structure ensures it does not react with other substances it comes into contact with.

This non-reactive nature prevents material degradation, ensuring that components made from PTFE maintain their physical properties over their entire service life.

Immunity to Common Corrosives

PTFE exhibits broad resistance to the most common and aggressive industrial chemicals. This includes strong acids, bases, and a wide variety of organic solvents.

This comprehensive resistance eliminates the risk of material swelling, cracking, or chemical corrosion, which are common failure points for lesser materials.

Stability with Aggressive Fuels and Fluids

The material excels in contact with various automotive and industrial fluids. It is fully compatible with chemically aggressive oils, diesel, gasoline, and alternative fuels.

This makes it an ideal choice for components like rotating shaft seals, where contact with these fluids is constant and performance cannot be compromised.

Practical Applications in Demanding Industries

The theoretical resistance of PTFE translates directly into reliable performance across a range of industries where chemical exposure is a constant operational reality. Its versatility allows it to be used in multiple forms, from structural components to protective liners.

Chemical Processing and Laboratories

In chemical plants and lab settings, PTFE is a go-to material for piping systems, gaskets, and equipment. Its inertness prevents contamination of the process media and protects the equipment itself.

It is often supplied as a bore liner or "PTFE envelope" to shield standard pipe gaskets from direct chemical attack, extending the life of the entire system.

Aerospace and Extreme Environments

PTFE's reliability extends to the most extreme conditions, including the vacuum of space and severe atmospheric temperatures.

Its chemical stability is not compromised by these environmental stressors, making it a critical material for components in aeronautical engineering and aerospace applications.

Weathering and Environmental Durability

Beyond targeted chemical exposure, PTFE is also highly resistant to general environmental factors. It is not affected by harsh weather conditions, UV radiation, or environmental contaminants.

This gives the material a long and stable shelf life, ensuring its properties remain consistent even after prolonged exposure to the elements.

Understanding the Performance Trade-offs

While its chemical resistance is nearly absolute, selecting PTFE requires a holistic view of the application's demands. The decision to use it involves understanding its strengths in context with other material properties.

Focus is on Chemical, Not Mechanical, Strength

PTFE is chosen for its chemical inertness, not its mechanical rigidity or strength compared to metals. In high-load applications, its physical properties like tensile strength and resistance to creep must be considered.

Often, its role is to protect a stronger, but less chemically resistant, structural material.

Application-Specific Design

The use of PTFE as a liner or envelope is a perfect example of this trade-off. It provides the chemical shield while a different material provides the mechanical structure and sealing force.

This design strategy leverages PTFE's primary strength where it is needed most—at the point of chemical contact.

Temperature as a Performance Boundary

While PTFE performs reliably across an exceptionally wide temperature range, all polymers have thermal limits. The combination of extreme temperatures and aggressive chemicals should always be evaluated to ensure operation remains within the material's specified service range.

Making the Right Choice for Your Application

To leverage PTFE's capabilities effectively, align your material choice with your primary operational challenge.

- If your primary focus is containing highly corrosive media: Use PTFE as a liner or in components like gaskets and seals to protect the larger system from chemical attack.

- If your primary focus is long-term reliability in a variable chemical environment: Select PTFE for its stability against a broad spectrum of chemicals, ensuring it won't degrade, swell, or crack over time.

- If your primary focus is performance in both chemical and extreme temperature conditions: PTFE is a uniquely suitable material for applications in aerospace and heavy industry where both factors are critical.

Ultimately, choosing PTFE is a decision for unparalleled chemical inertness and long-term operational peace of mind.

Summary Table:

| Property | PTFE Performance |

|---|---|

| Chemical Resistance | Excellent resistance to nearly all acids, bases, solvents, and fuels. |

| Thermal Stability | Performs reliably across a wide temperature range. |

| Durability | Maintains integrity without degrading, swelling, or corroding over time. |

| Key Applications | Seals, liners, gaskets, and labware in semiconductor, medical, and chemical processing. |

Need a reliable PTFE component for a harsh chemical environment?

KINTEK specializes in manufacturing high-precision PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We ensure your parts deliver unmatched chemical resistance and long-term performance, from prototypes to high-volume production.

Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why are PTFE seals preferred over traditional rubber seals? Superior Performance in Extreme Conditions

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the primary characteristics of PTFE seals? Unmatched Performance for Extreme Conditions