At its core, expanded PTFE (ePTFE) is a critical sealing material in the oil and gas industry, primarily used as a gasket or tape for chemical pipe flanges. Its unique properties create a durable, reliable seal that prevents dangerous leaks of volatile chemicals, ensuring both operational safety and environmental protection.

The true value of ePTFE isn't just that it seals, but that it solves the industry's most challenging sealing problems—especially in the field. Its unique combination of chemical inertness, temperature resistance, and physical adaptability makes it indispensable for maintaining integrity in harsh and unpredictable environments.

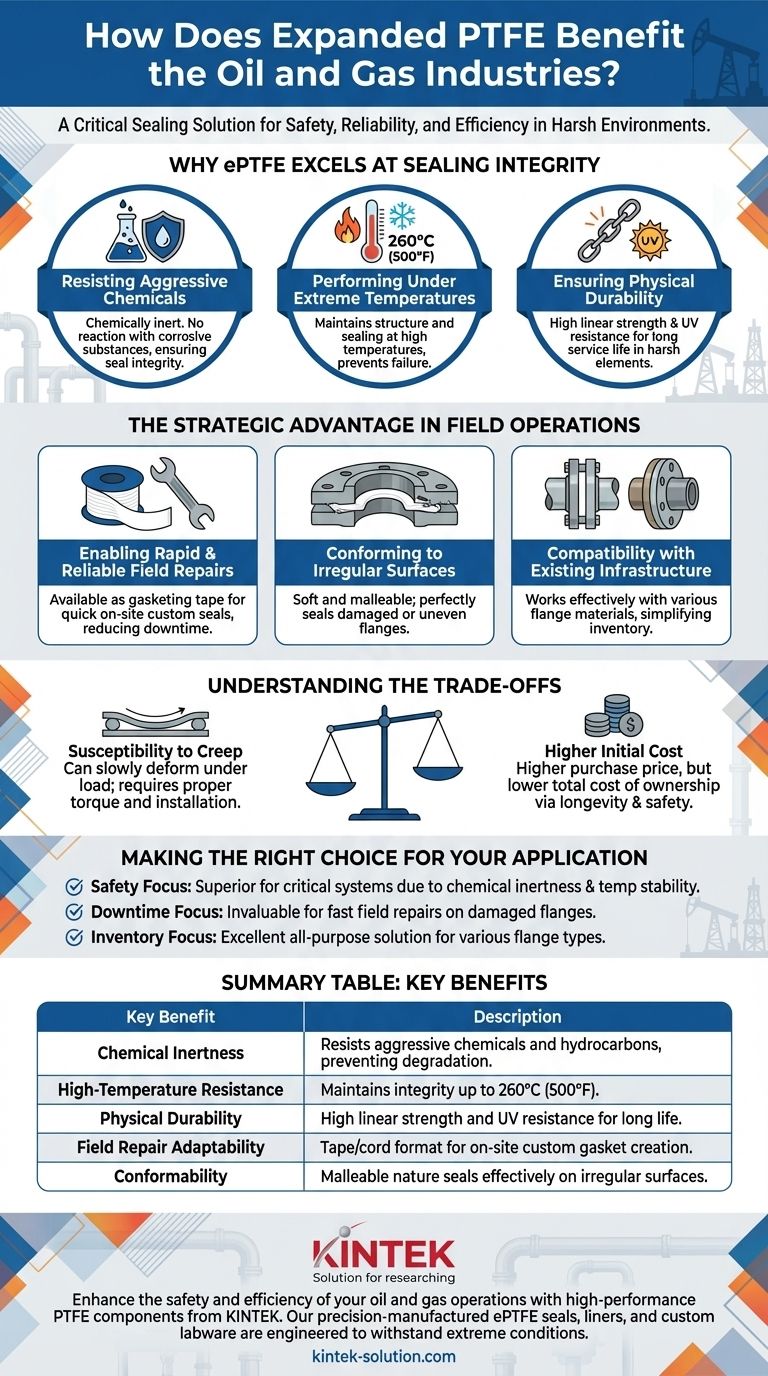

Why ePTFE Excels at Sealing Integrity

The operational environment of the oil and gas industry is defined by extreme conditions. Materials are constantly challenged by aggressive chemicals, high temperatures, and significant physical stress. ePTFE is engineered to withstand this environment.

Resisting Aggressive Chemicals

The most fundamental benefit of ePTFE is its chemical inertness. It does not react with the vast majority of chemicals, acids, and corrosive substances found in oil and gas processing.

This ensures the seal will not degrade or fail when exposed to hydrocarbons or other aggressive media, a common failure point for lesser materials.

Performing Under Extreme Temperatures

Oil and gas operations frequently involve high-temperature processes. ePTFE maintains its structural integrity and sealing capability at temperatures up to 260°C (500°F).

This high-temperature resistance prevents the seal from becoming brittle or melting, which would lead to catastrophic failure.

Ensuring Physical Durability

Beyond chemical and thermal stability, ePTFE exhibits high linear strength and UV resistance.

This makes it suitable for equipment exposed to the elements and mechanical stress, ensuring a long and reliable service life without frequent replacement.

The Strategic Advantage in Field Operations

While its material properties are impressive, ePTFE's greatest benefit may be its practicality and versatility, particularly for maintenance and repair work performed on-site.

Enabling Rapid and Reliable Field Repairs

ePTFE is commonly available in the form of a gasketing tape or cord on a spool. This format is ideal for quick field repairs, as it is lightweight and easy to carry to remote locations.

Technicians can instantly create a custom-fit gasket on-site, dramatically reducing downtime compared to waiting for a pre-cut replacement part.

Conforming to Irregular Surfaces

Unlike rigid, pre-formed gaskets, ePTFE is soft and malleable. It is exceptionally well-suited for large, complex, or even damaged flanges.

The material conforms perfectly to surface imperfections, scratches, and warping, creating a tight and effective seal where a standard gasket would likely fail.

Compatibility with Existing Infrastructure

This versatile material works effectively with flanges made from various materials, including steel and other alloys.

This eliminates the need to stock numerous types of specialized gaskets, simplifying inventory and ensuring maintenance crews always have a reliable sealing solution on hand.

Understanding the Trade-offs

No material is perfect, and making an informed decision requires understanding a material's limitations. While highly effective, ePTFE has considerations that are important in an industrial context.

Susceptibility to Creep

Like all PTFE-based materials, ePTFE can be susceptible to creep, or "cold flow," over long periods, especially under high compressive loads and temperatures. This means the material can slowly deform, potentially loosening the seal over time.

Proper installation and bolt torque procedures are critical to mitigate this effect and ensure a long-lasting seal.

Higher Initial Cost

ePTFE is a high-performance material, and its initial purchase price can be higher than that of common elastomeric or fiber gaskets.

However, this cost is often justified by its longer service life, reduced downtime, and enhanced safety, which translate to a lower total cost of ownership.

Making the Right Choice for Your Application

Selecting the correct sealing material depends entirely on the operational goal and the specific demands of the application.

- If your primary focus is safety in critical systems: ePTFE is a superior choice for its unmatched chemical inertness and high-temperature stability.

- If your primary focus is minimizing operational downtime: The adaptability of ePTFE gasketing tape for fast, reliable field repairs on damaged flanges is invaluable.

- If your primary focus is simplifying maintenance inventory: ePTFE's versatility across different flange types and sizes makes it an excellent all-purpose solution.

Ultimately, ePTFE provides a powerful combination of resilience and adaptability, making it an indispensable tool for ensuring safety and efficiency in the demanding world of oil and gas.

Summary Table:

| Key Benefit | Description |

|---|---|

| Chemical Inertness | Resists aggressive chemicals and hydrocarbons, preventing seal degradation. |

| High-Temperature Resistance | Maintains integrity and sealing capability up to 260°C (500°F). |

| Physical Durability | High linear strength and UV resistance for long service life. |

| Field Repair Adaptability | Tape/cord format allows for on-site, custom gasket creation to minimize downtime. |

| Conformability | Malleable nature seals effectively on irregular or damaged flange surfaces. |

Enhance the safety and efficiency of your oil and gas operations with high-performance PTFE components from KINTEK.

Our precision-manufactured ePTFE seals, liners, and custom labware are engineered to withstand the extreme conditions of the semiconductor, medical, laboratory, and industrial sectors. Whether you need a reliable prototype or a high-volume order, we deliver the durability and chemical resistance your critical applications demand.

Contact us today to discuss your specific sealing challenges and discover how our custom fabrication expertise can benefit your projects.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability