The warning light flashes. A critical pump grinds to a halt, and production stops with it. The diagnosis is depressingly familiar: another failed seal. For any engineer working with high-performance systems—be it in chemical processing, semiconductor manufacturing, or medical devices—this scene is a recurring nightmare.

You’ve spent weeks, maybe months, chasing down a persistent leak. You’ve replaced the O-ring, checked the gland, and hoped for the best. Yet, the failure returns, costing you another day of downtime, another batch of spoiled product, and another blow to your project timeline. It feels like a game of chance, but it’s not. You’re not fighting bad luck; you’re fighting the fundamental limitations of your materials.

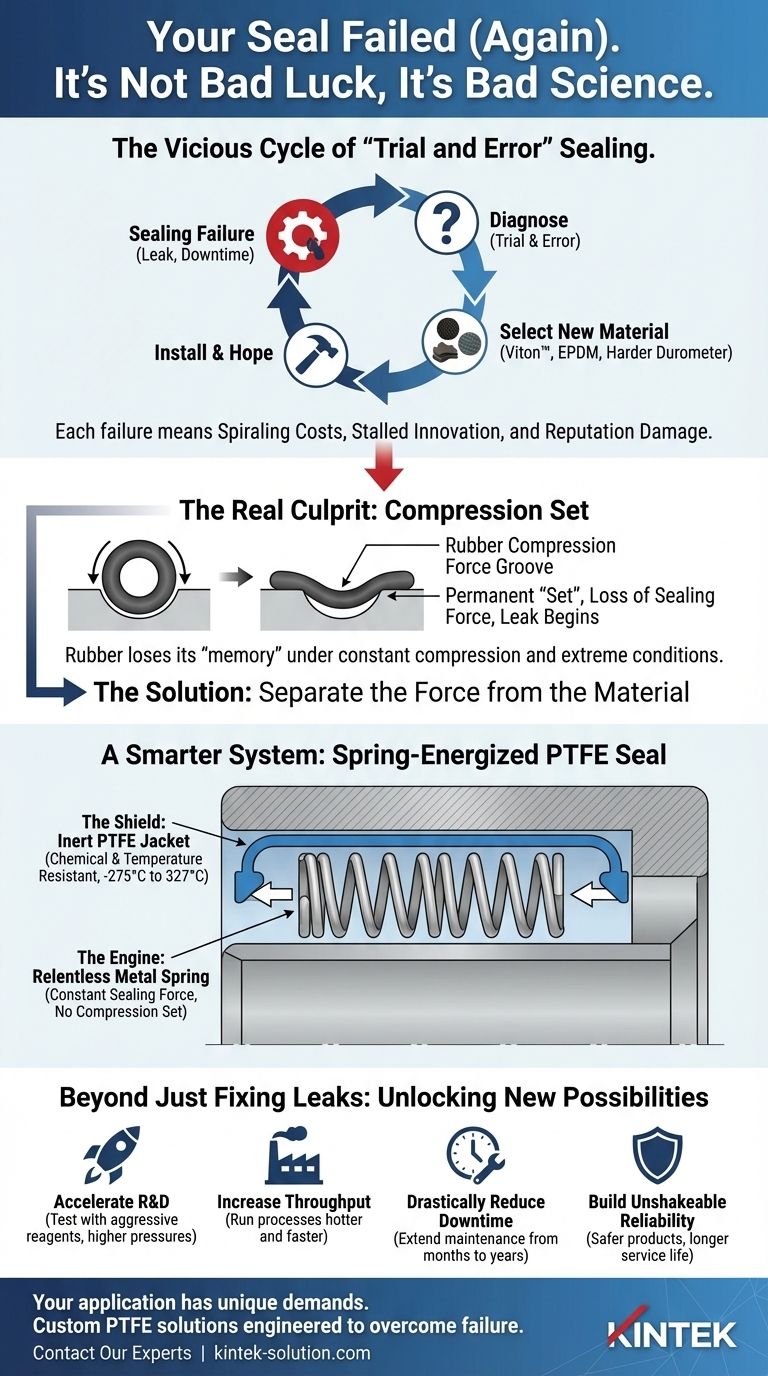

The Vicious Cycle of "Trial and Error" Sealing

When a seal fails under aggressive chemicals, high pressures, or extreme temperatures, the typical response is to look for a "better" rubber.

"Maybe a Viton™ seal will hold up better than the EPDM we're using?" "Could a harder durometer solve the extrusion issue?" "Perhaps we just got a bad batch of O-rings."

This approach leads to a costly cycle of trial, failure, and replacement. You swap one elastomer for another, hoping for a different outcome. While one material might offer slightly better chemical resistance, it may have a lower temperature rating. The "fix" for one problem often creates another.

This isn't just a technical nuisance; it's a significant business drag.

- Spiraling Costs: Each failure means expensive downtime, emergency maintenance labor, and potentially millions in lost or contaminated product.

- Stalled Innovation: R&D projects are hamstrung because you can't find an off-the-shelf seal that can survive the demanding test conditions for a new medical instrument or aerospace component.

- Reputation Damage: When a seal fails in a customer's equipment, it's not just a leak—it's a product failure that leads to warranty claims and a loss of trust in your engineering.

The frustrating truth is that this cycle continues because these "solutions" only address the symptoms. The root cause lies deeper, in the very nature of the materials being used.

The Real Culprit: Why Rubber Seals Are Designed to Fail

Traditional elastomeric seals like O-rings rely on a single property: their own "springiness" or elasticity. They are installed in a groove and squeezed, and this compression creates the sealing force. For many everyday applications, this works perfectly well.

But in extreme environments, this design has a fatal flaw.

The Inevitable Weakness: A "Compression Set" Story

Think of a rubber band left stretched out in the sun. Over time, it becomes brittle, loses its ability to snap back, and eventually breaks. Elastomeric seals suffer a similar fate known as compression set.

When held under constant compression, especially at high temperatures or when exposed to certain chemicals, the polymer chains in the rubber permanently rearrange themselves. The material loses its memory and its ability to "push back." It takes a permanent "set" in its compressed shape.

Once this happens, it no longer exerts sufficient force against the hardware to maintain a tight seal. A slight pressure drop, a minor vibration, or a temperature fluctuation is all it takes for a leak to begin. At this point, no amount of troubleshooting will help—the seal's inherent ability to function is gone forever.

This is why swapping from one type of rubber to another is often a losing battle. You're just choosing a different material that will eventually succumb to the same fundamental mode of failure. To break the cycle, you don't need a better rubber—you need a better engineering system.

A Smarter System: Separating the Force from the Material

To create a truly reliable seal for extreme conditions, you must solve two problems: material degradation and the loss of sealing force. The most robust solution is to separate these two functions. You need:

- A sealing jacket made from a material that is virtually immune to chemicals and temperature extremes.

- An energizing element that provides a constant, permanent sealing force that never "gets tired."

This is the elegant engineering principle behind the spring-energized PTFE seal. It’s not just a better component; it’s a superior design philosophy.

The Shield: An Inert PTFE Jacket

The seal's outer body, or jacket, is precision-machined from Polytetrafluoroethylene (PTFE) and other high-performance polymers. Unlike rubber, PTFE is one of the most chemically inert substances known. It is unfazed by virtually all industrial chemicals, solvents, and fuels. It also boasts an incredible operating temperature range, from cryogenic lows (-275°C / -425°F) to high heat (327°C / 575°F), where elastomers would either freeze solid or turn to ash. This jacket forms an impenetrable shield against the harshest process conditions.

The Engine: A Relentless Metal Spring

Nestled inside the PTFE jacket is a metal spring energizer. This is the "engine" of the seal. Unlike an elastomer that relies on its own fragile memory, this spring provides a constant, active mechanical force, pushing the lips of the PTFE jacket outwards.

Crucially, this spring never suffers from compression set. It continuously compensates for wear on the jacket, minor hardware misalignments, and pressure fluctuations, ensuring a tight seal throughout a much longer service life. Even as the PTFE jacket slowly wears over millions of cycles, the spring follows it, maintaining a consistent sealing force.

This synergy—a resilient spring inside an inert jacket—is what allows these seals to reliably handle pressures exceeding 30,000 psi and perform in high-speed rotary applications where traditional seals would instantly overheat and fail.

Beyond Just Fixing Leaks: What's Possible When Your Seal Is No Longer the Weakest Link?

When you engineer failure out of your system by moving from a passive rubber O-ring to an active, spring-energized sealing system, you do more than just stop a leak. You unlock new levels of performance, reliability, and innovation.

- Accelerate R&D: Push the boundaries of your new designs. Test with more aggressive reagents, at higher pressures, or for longer durations, knowing your seal won't be the point of failure.

- Increase Throughput: In semiconductor or chemical processing, you can run processes hotter and faster to increase yield, confident that your seals can handle the intensified conditions without causing contamination.

- Drastically Reduce Downtime: Extend maintenance intervals on critical pumps, valves, and actuators from months to years. Imagine replacing a seal as part of a planned multi-year overhaul, not as an emergency fire-drill.

- Build Unshakeable Reliability: For medical devices or aerospace components, a seal that is immune to aging and embrittlement means a product that is safer, more reliable, and has a longer shelf-life and in-service life.

Solving your most persistent sealing challenges isn't about finding a magic bullet. It’s about understanding the root cause of failure and choosing a solution that is engineered to overcome it. Moving to a superior sealing system frees your team to focus on innovation and optimization, rather than constantly fighting fires.

Your application has unique demands, and achieving this level of reliability requires more than an off-the-shelf part; it requires a precisely engineered component. We specialize in fabricating custom PTFE solutions that are built to solve your specific challenges, from one-off prototypes to high-volume production. If you're ready to break the cycle of failure and unlock new performance possibilities, let's talk about your project. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

Related Articles

- The Unseen Workhorse: Why PTFE Is the Default Choice for Impossible Problems

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- The Physics of Trust: Why PTFE Is the Bedrock of High-Stakes Electronics

- How PTFE Solves Critical Industrial Challenges Through Material Superiority