You know the feeling. You’ve just completed a long, automated analytical run. The first dozen samples look perfect—clean baselines, sharp peaks, textbook precision. Then, suddenly, the data goes off the rails. A drifting baseline, a bizarre ghost peak, or a result that’s a complete outlier.

Your day is no longer about moving your project forward. It’s now dedicated to a frustrating investigation: Was it the sample prep? Did the instrument calibration drift? Or is it just bad luck? You rerun the samples, consuming more time, more expensive solvents, and more of your budget, hoping the problem just… goes away.

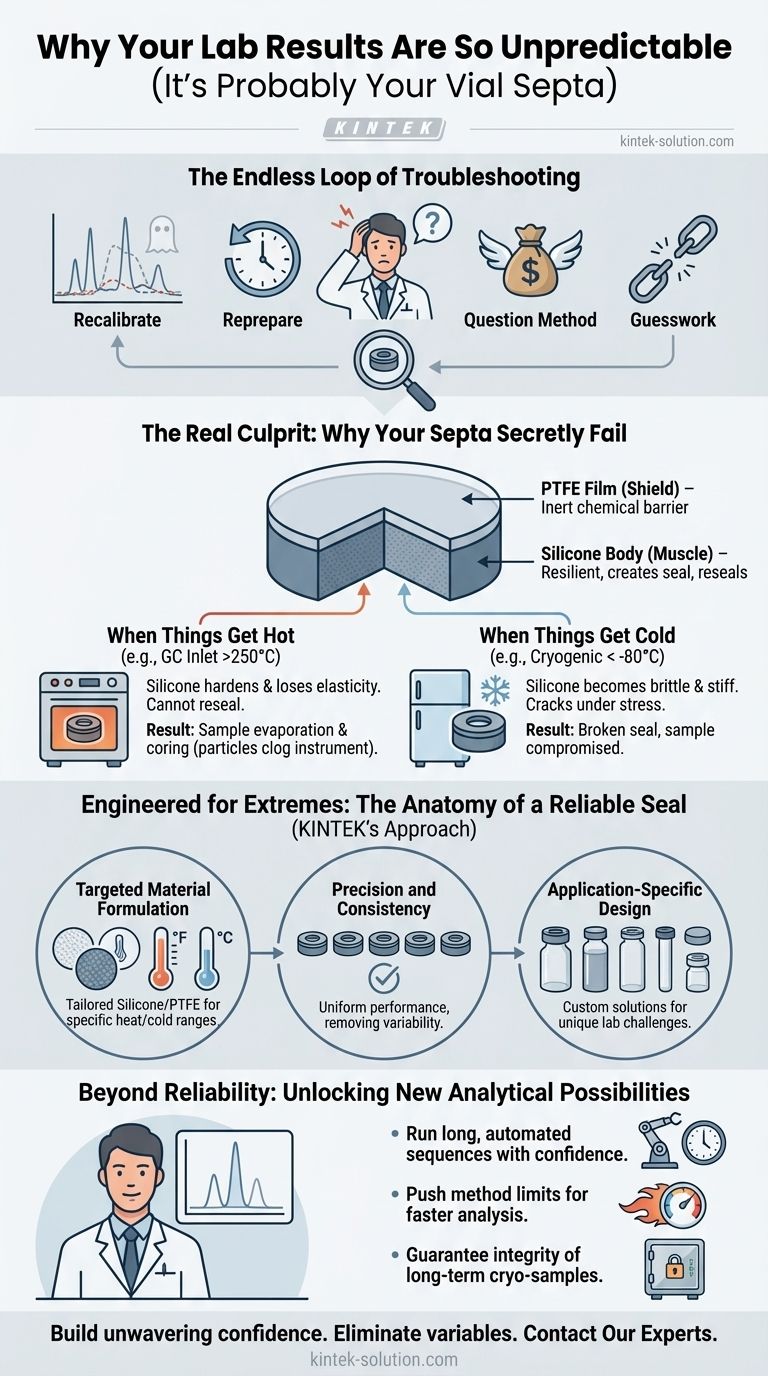

The Endless Loop of Troubleshooting

This scenario is a common and costly ritual in labs everywhere. When faced with inconsistent results, the natural response is to look at the most complex parts of the process. We spend hours recalibrating multi-million dollar instruments, preparing fresh standards, and questioning our own validated methods.

When these efforts fail, we often resort to guesswork. We might blame a "bad batch" of vials or switch to a different, sometimes cheaper, brand of septa, crossing our fingers for a better outcome.

But this approach is a gamble, not a solution. The negative consequences are very real:

- Project Delays: A single analytical failure can halt a stability study or a batch release, pushing back critical development timelines.

- Wasted Resources: Every failed run means throwing away not just time, but also high-purity solvents, expensive reagents, and often, irreplaceable samples.

- Eroding Confidence: When data is unreliable, it undermines the credibility of the lab’s findings, creating doubt in everything from early-stage research to final product quality control.

The problem is that these "solutions" are just shots in the dark. They fail because they address the symptoms (bad data) without ever diagnosing the true, underlying cause.

The Real Culprit: Why Your Septa Secretly Fail

The source of this chaos is often hiding in plain sight: that tiny, seemingly simple PTFE/silicone septum sealing your vial. We tend to think of it as a simple plug, but it’s a high-performance component engineered to perform a critical job under extreme stress. Its failure is not random; it’s a predictable event rooted in material science.

A high-quality septum has two key parts, each with a specific job:

- The Silicone Body: This is the "muscle." It’s a resilient, springy material designed to provide the physical force that creates an airtight seal. Crucially, it must also reseal perfectly after being punctured by a needle.

- The PTFE Film: This is the "shield." A micro-thin layer of PTFE faces your sample, providing an inert chemical barrier. It ensures that nothing from the septum contaminates your sample and that your sample doesn't react with the seal.

The problem is that extreme temperatures attack the silicone "muscle."

When Things Get Hot

In a heated Gas Chromatography (GC) inlet (often >250°C) or a long-term stability study, a low-grade silicone will harden and lose its elasticity, like rubber left in an oven. It can no longer spring back to reseal the puncture, causing sample evaporation. Worse, the needle can punch out a tiny piece of the hardened material—a phenomenon called "coring"—which falls into your sample and can clog your instrument.

When Things Get Cold

During cryogenic storage (below -80°C), the opposite happens. The wrong type of silicone becomes brittle and stiff, like plastic left in a freezer. A small bump during handling or the stress of temperature change can cause it to crack, instantly breaking the seal and compromising or destroying a priceless biological sample.

This is why simply switching brands without understanding their material composition is a flawed strategy. You are not solving the root problem, which is a fundamental mismatch between the material’s properties and the physical demands of your application.

Engineered for Extremes: The Anatomy of a Reliable Seal

To truly solve this problem, you don't need luck; you need the right tool for the job. You need a septum that is not just a piece of rubber and plastic, but an engineered component designed from the ground up to withstand the specific thermal stresses of your workflow.

This is precisely where KINTEK's approach to manufacturing makes a critical difference. We don’t just make PTFE components; we engineer solutions based on a deep understanding of material science. Our PTFE/silicone septa are a direct answer to the failures described above.

-

Targeted Material Formulation: We don’t believe in a "one-size-fits-all" solution. Our septa are made from specific grades of silicone and PTFE, formulated to maintain their elasticity, resealability, and chemical inertness at specific temperature ranges, whether it’s the intense heat of a GC inlet or the deep cold of cryogenic storage.

-

Precision and Consistency: The root of good data is consistency. Our precision manufacturing processes ensure that every single septum performs exactly like the last. This removes a major source of variability from your analysis, so you can trust your results run after run, batch after batch.

-

Application-Specific Design: Because we specialize in custom fabrication, we can create components designed for your unique challenges. Whether it's a standard autosampler vial or a custom piece of labware, we can provide a sealing solution that is perfectly matched to your process requirements.

Beyond Reliability: Unlocking New Analytical Possibilities

When you stop worrying about whether your basic components will fail, you free up your team to focus on what truly matters: innovation and discovery. Eliminating the septum as a point of failure doesn’t just prevent bad data; it opens up new potential.

Imagine a lab where:

- You can run long, complex, automated sequences overnight with complete confidence in the data you’ll find in the morning.

- You can push the limits of your methods, using higher temperatures for faster analysis, knowing your seals won’t bleed or core.

- You can guarantee the integrity of priceless, long-term cryo-stored samples, protecting years of research.

This isn't about just buying a better component. It's about building a more robust, reliable, and efficient foundation for all your analytical work. It’s about transforming troubleshooting time into discovery time.

Your projects face unique challenges, from ensuring drug safety to pioneering new materials. A component failure should never be the bottleneck. If you're tired of chasing down elusive errors and want to build unwavering confidence in your data, our team is here to help. Let's discuss how precision-engineered PTFE components can eliminate variables and move your most critical projects forward. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- PTFE Deep Evaporating Dishes Customizable Laboratory and Industrial Solutions

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

Related Articles

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- Your "Inert" PTFE Component Might Be the Real Source of System Failure

- The PTFE Paradox: Why the 'Perfect' Material Fails—And How to Make It Work