It’s a frustratingly familiar scene: hours of careful assembly on a critical piece of equipment, a system ready for a high-stakes run, and then you spot it—the slow, persistent drip of a newly installed seal. For engineers and technicians in semiconductor, medical, or industrial labs, this isn't just an annoyance; it's a direct threat to project timelines, batch purity, and operational costs.

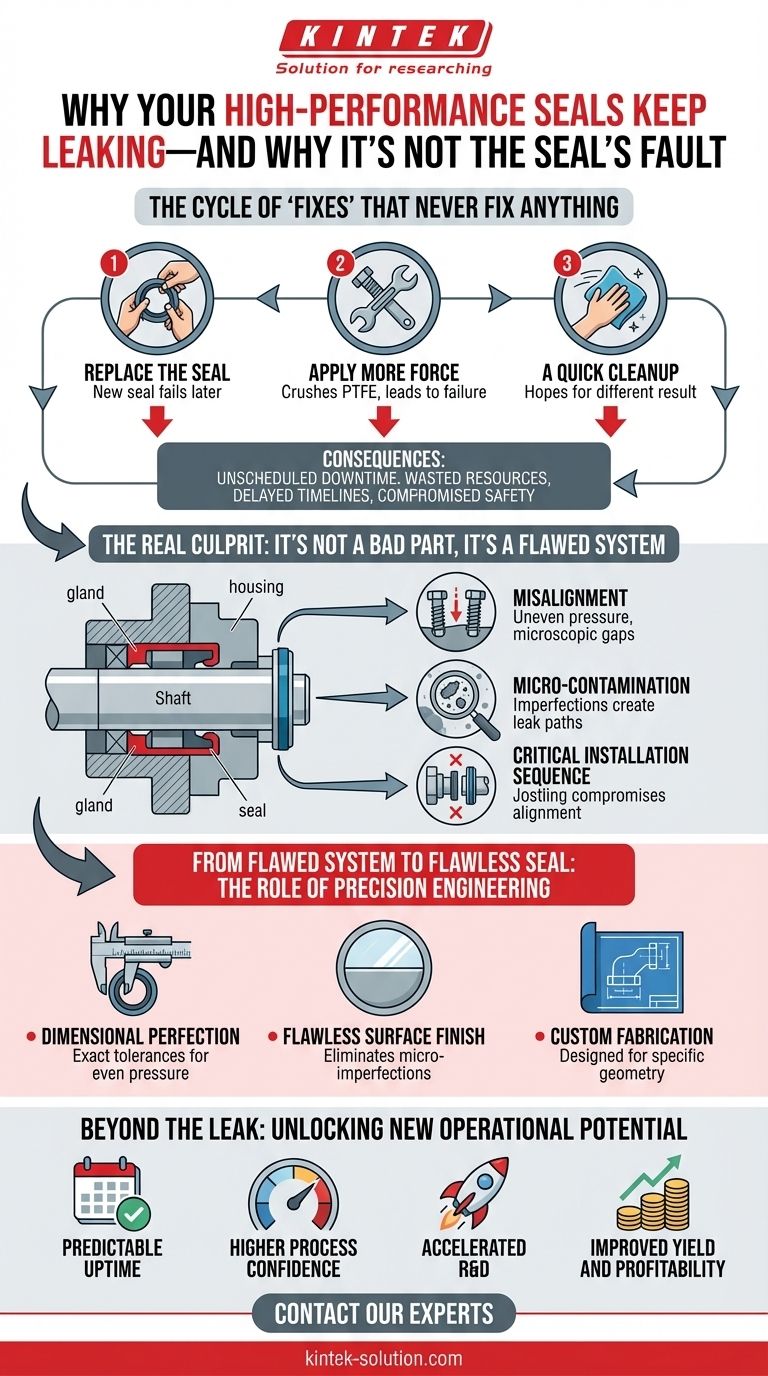

The Cycle of 'Fixes' That Never Fix Anything

When a seal leaks, the immediate instinct is to blame the component. So begins the costly ritual of trial and error:

- Replace the Seal: You grab another PTFE seal from the box, assuming the first one was a dud. You carefully reinstall it, only to find the same leak appears hours or days later.

- Apply More Force: Believing the seal isn't tight enough, you crank down on the gland bolts. This might stop the leak temporarily, but it often leads to a much bigger failure down the line by crushing the precision-engineered PTFE.

- A Quick Cleanup: You disassemble everything, give the surfaces a quick wipe, and try again, hoping for a different result.

Each failed attempt isn't just a waste of a component. It translates into very real business consequences:

- Unscheduled Downtime: Critical equipment is taken offline, halting production or research.

- Wasted Resources: Expensive process fluids are lost, and entire product batches can be contaminated and ruined.

- Delayed Timelines: Projects are pushed back, affecting launch dates and customer commitments.

- Compromised Safety: In many applications, a leak is not just a mess—it's a potential safety hazard.

After a few rounds of this, it’s easy to conclude that you just have a batch of "bad seals." But what if the seal was never the problem to begin with?

The Real Culprit: It's Not a Bad Part, It's a Flawed System

The persistent failure of high-performance seals almost never comes down to a single faulty part. It stems from a fundamental misunderstanding: treating the installation as a simple parts-swap instead of the creation of a precision-engineered system.

A seal doesn't work in isolation. It functions as part of an assembly that includes the gland, the housing, and the shaft. For a seal to be effective, these components must form a perfect, continuous barrier against pressure.

This is where the common "fixes" fail so spectacularly:

- The Problem of Misalignment: When you tighten gland bolts unevenly—instead of using a precise crisscross pattern—you are invisibly tilting the gland. Even a microscopic tilt creates an uneven pressure point on the PTFE seal, leaving a tiny gap on the opposite side. Under pressure, that gap becomes a leak path. Overtightening only makes this warping worse.

- The Threat of Micro-Contamination: To the naked eye, a metal surface may look clean after a quick wipe. But at a microscopic level, it can still harbor tiny burrs, scratches, or particles of debris. Each one of these imperfections is a potential channel for fluid to escape. A brand-new seal installed on a poorly prepared surface is destined to fail.

- The Critical Installation Sequence: As the source instructions highlight, the static ring and gland must be installed as a single unit before the moving ring. Why? This ensures the stationary components are perfectly seated without being disturbed. Installing parts out of order risks jostling them, compromising the alignment you worked so hard to achieve.

In short, you can have the best seal in the world, but if you install it into a flawed system, it will leak.

From Flawed System to Flawless Seal: The Role of Precision Engineering

Understanding this principle changes everything. The goal is no longer just to "install a seal," but to "create a perfectly aligned, contaminant-free sealing system."

To achieve this reliably, you need to start with components that are engineered to make this systemic approach possible. The installation process is demanding, and it requires a foundation of absolute precision. This is where the quality of your components becomes non-negotiable.

A truly high-performance PTFE seal from KINTEK is designed with this system in mind:

- Dimensional Perfection: Our precision production process ensures that every seal has exact tolerances. This dimensional stability is critical for achieving the even pressure and perfect face-to-face contact required for a leak-free system. It removes component variation as a source of failure.

- Flawless Surface Finish: We manufacture components with impeccably smooth surfaces, free from the micro-imperfections that can turn into leak paths. This provides the ideal foundation for creating a perfect seal.

- Custom Fabrication for a Perfect Fit: Often, sealing issues arise from using a "close-enough" part. Our ability to custom-fabricate components—from prototype to high-volume—ensures you have a seal designed for the specific geometry and demands of your equipment, eliminating a major variable in the sealing equation.

When you start with a component that is geometrically perfect, you make the job of creating a perfect installation system infinitely easier and more repeatable.

Beyond the Leak: Unlocking New Operational Potential

When chronic seal failures are no longer a variable in your operations, you move from a state of reactive problem-solving to proactive innovation.

Resolving this fundamental issue for good doesn't just mean fewer puddles on the floor. It means:

- Predictable Uptime: You can plan maintenance on your own schedule, not on the seal's schedule.

- Higher Process Confidence: You can push your equipment to its intended limits—higher pressures, more aggressive chemicals, longer run times—with confidence in its integrity.

- Accelerated R&D: Your team can focus on developing the next breakthrough, not troubleshooting the same basic equipment failures.

- Improved Yield and Profitability: With contamination and downtime eliminated, your operational efficiency and output increase directly.

A reliable seal is more than just a component; it's the foundation of predictable performance and continuous improvement. If you're ready to break the cycle of troubleshooting and focus on what you do best, our team is here to help. We don't just supply parts; we partner with you to solve the systemic challenges that stand in the way of your goals. Let's discuss the specific demands of your project. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

Related Articles

- Your "Inert" PTFE Component Might Be the Real Source of System Failure

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- How PTFE Solves Critical Industrial Challenges Through Material Superiority