It’s a familiar and frustrating scene: a critical process line is down. Again. A small puddle of a costly or hazardous chemical has collected beneath a joint, signaling another unscheduled shutdown. You’ve replaced this exact seal or gasket three times in the last year, and each failure chips away at production targets, inflates maintenance budgets, and adds another layer of risk to your operations.

You’ve tried everything, so why does this keep happening?

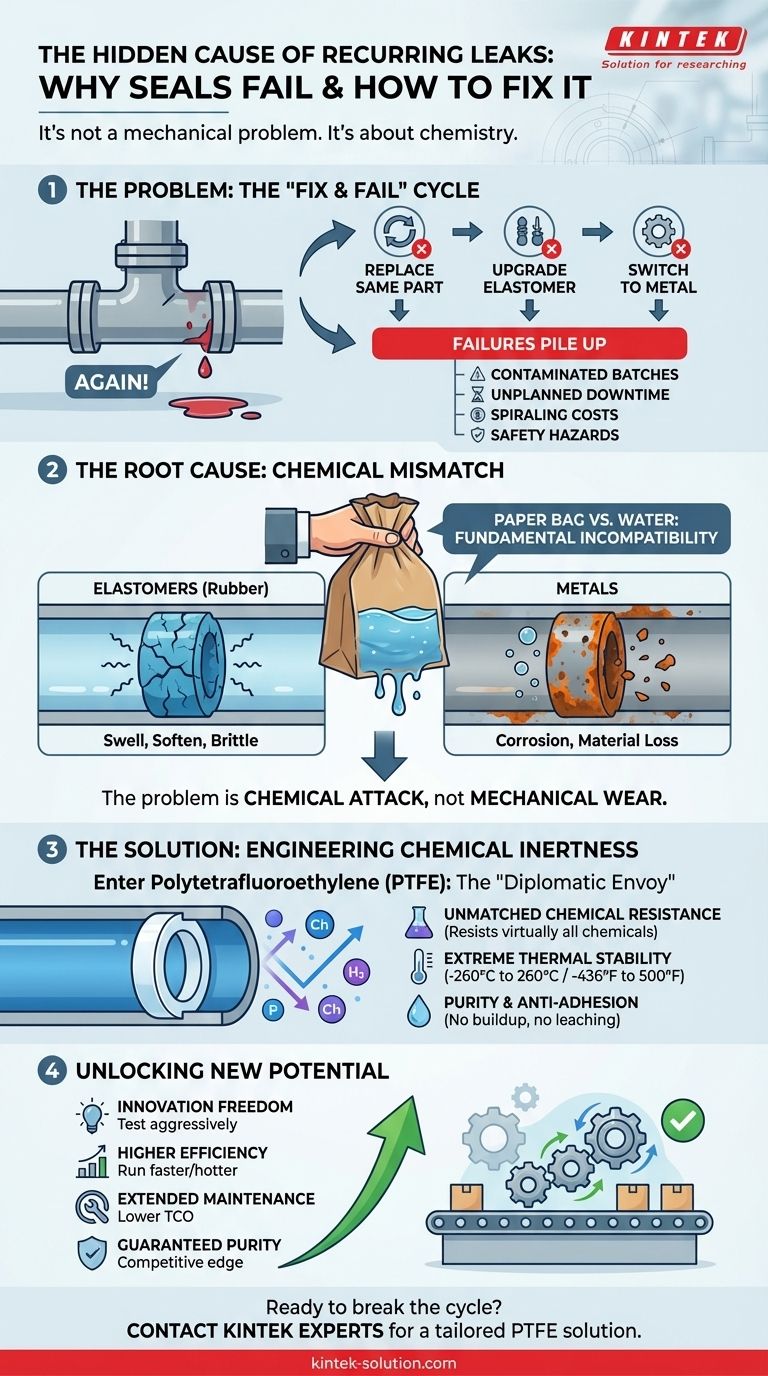

Why "Stronger" Isn't Always the Answer: The Misguided Search for a Fix

When a seal or expansion joint fails, the immediate instinct is to treat it as a mechanical problem. The logic seems sound: the component wasn't strong enough to handle the pressure or flexible enough to absorb the vibration.

This leads down a predictable—and often fruitless—path of troubleshooting:

- Replace with the same part: The simplest solution. You hope the last one was just a fluke, a single defective part from a bad batch. But a few months later, the leak returns.

- "Upgrade" to a heavy-duty elastomer: You switch from a standard rubber to a "tougher" or more expensive variant, believing more bulk or a higher pressure rating will solve the issue. Yet, the same slow degradation occurs.

- Switch to metal: For high-pressure systems, you might even opt for a metal joint, thinking its rigidity will guarantee a perfect seal. But soon, you find signs of corrosion compromising the system.

Each of these attempts treats the symptom—the physical failure—while completely ignoring the root cause. The negative business consequences pile up:

- Contaminated Batches: In semiconductor, medical, or pharmaceutical applications, even microscopic material degradation can leach impurities, ruining an entire high-value production run.

- Unplanned Downtime: Every hour your line is down for a "minor" repair is an hour of lost revenue and productivity.

- Spiraling Maintenance Costs: The budget for replacement parts and labor hours balloons, diverting resources from innovation and process improvement.

- Safety Hazards: In chemical processing, a seemingly small leak can expose personnel to aggressive acids or solvents, creating a serious safety liability.

The cycle continues because the problem isn't about mechanical strength. It's about chemistry.

The Real Culprit: When Your Materials Are Chemically Mismatched

Imagine trying to carry water in a paper bag. The bag is perfectly capable of holding sand or other dry goods, but the moment you add water, its structural integrity dissolves. The bag didn't fail because it was "weak"; it failed because it was fundamentally incompatible with its contents.

This is precisely what happens inside your process lines.

Standard elastomers and even many metals are in a constant, slow-motion battle with the media they contain. Aggressive chemicals, solvents, and extreme temperatures don't just put pressure on a seal; they actively attack its molecular structure.

- Elastomers (Rubber): Can swell, soften, or become brittle when exposed to incompatible chemicals, losing their sealing ability long before any physical tear is visible.

- Metals: Are susceptible to corrosion from acids and bases, slowly eating away at the material and compromising the seal from the inside out.

The "heavy-duty" replacements you’ve been trying are just stronger paper bags. They may last a little longer, but they are destined to fail because they are fighting a chemical battle, not a mechanical one. The only way to win is to stop fighting and choose a material that is immune to the conflict altogether.

Solving the Root Cause: Engineering with Chemical Inertness in Mind

To achieve permanent system integrity, you don't need a stronger material; you need a non-reactive one. You need a component that is completely indifferent to the aggressive chemistry and extreme temperatures of your process.

This is the principle behind Polytetrafluoroethylene (PTFE).

PTFE isn't just another plastic. It is a high-performance fluoropolymer engineered from the ground up for one primary purpose: to be almost completely chemically inert. It’s the material science equivalent of a diplomatic envoy—it simply doesn't react with the hostile environment around it.

At KINTEK, we don't just sell PTFE parts; we engineer solutions based on this fundamental understanding of material science. Our precision-fabricated PTFE components are the ideal tool to solve this root cause because they are designed to address the specific failure points of conventional materials:

- Unmatched Chemical Resistance: Our high-purity PTFE is resistant to virtually all industrial chemicals, acids, and solvents. It doesn’t degrade, swell, or corrode, ensuring a stable, long-lasting seal.

- Extreme Thermal Stability: From cryogenic lows of -260°C to high-heat applications of 260°C (-436°F to 500°F), our PTFE components maintain their integrity where elastomers would shatter or melt.

- Purity and Anti-Adhesion: The inherently non-stick, pure surface of PTFE prevents media buildup and material leaching, protecting the integrity of your end product in sensitive applications like semiconductor manufacturing and medical devices.

By fabricating custom components to your exact specifications, we ensure the solution isn't just made from the right material—it's designed perfectly for your system's unique mechanical demands.

From Constant Repairs to Unlocking New Potential

Once you eliminate the chronic problem of material incompatibility, you do more than just stop leaks. You unlock a new level of operational freedom and innovation.

Imagine a future where:

- Your R&D team can experiment with more aggressive chemistries to develop next-generation products, knowing the equipment can handle it.

- You can run processes at higher temperatures to increase throughput and efficiency without fear of component degradation.

- Maintenance cycles are extended dramatically, reducing your total cost of ownership and freeing your engineering team to focus on value-added projects instead of firefighting.

- Product purity is guaranteed, giving you a competitive edge in quality-critical markets and eliminating the risk of costly batch contamination.

Solving recurring equipment failure isn't just about fixing a part; it's about removing a fundamental limitation on your business. If you're ready to break the "fix and fail" cycle and build a more resilient, innovative, and profitable operation, the first step is choosing the right material.

Your challenge is unique, and a one-size-fits-all solution won't cut it. Let's discuss the specific chemical and thermal demands of your system and engineer a PTFE solution that provides the reliability you've been searching for. Contact Our Experts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

Related Articles

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure