It’s a scenario familiar to many plant managers and process engineers. You’re speccing a new line for a highly corrosive chemical. On one hand, you have a quote for solid Hastelloy or another exotic alloy valve that could single-handedly consume a huge chunk of your project budget. On the other hand, you have the memory of the last "cost-effective" valve that failed, leading to a costly shutdown, a hazardous leak, and a mountain of paperwork.

You’re caught between a financial rock and an operational hard place. It feels like you have to choose between breaking the bank and risking a disaster. But what if this choice is a false one?

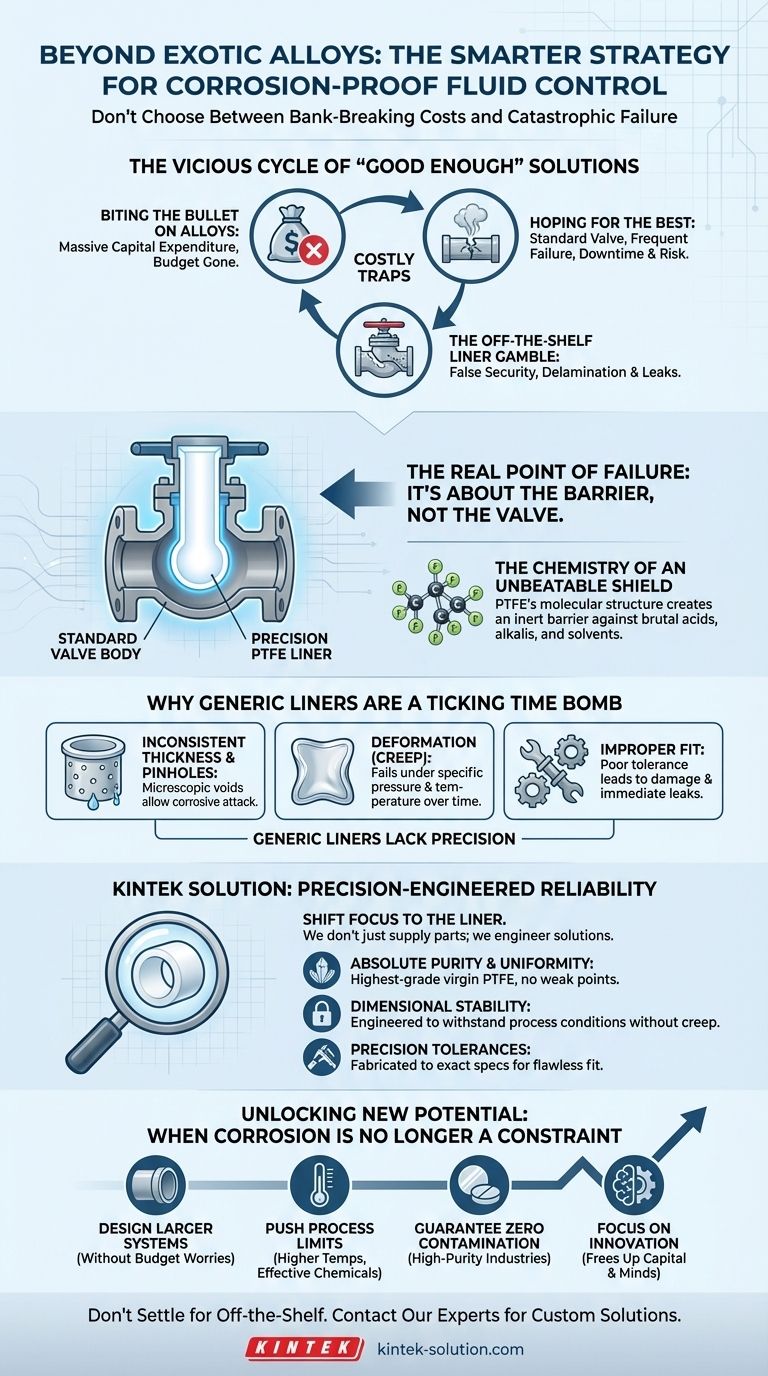

The Vicious Cycle of "Good Enough" Solutions

When faced with controlling aggressive media, teams often fall into one of three costly traps:

- Biting the Bullet on Alloys: You approve the massive capital expenditure for exotic alloy valves. The line is safe, but the project is now over budget, and funds that could have been used for innovation or other upgrades are gone forever.

- Hoping for the Best: You install a standard stainless steel valve, hoping the process conditions aren't that bad. This gamble rarely pays off, leading to frequent replacements, unplanned downtime, and the constant risk of a catastrophic failure.

- The Off-the-Shelf Liner Gamble: You choose a PFA/PTFE-lined valve, which seems like the perfect compromise. But weeks or months later, it fails. The liner delaminates, deforms under pressure, or develops a microscopic pinhole, allowing the corrosive media to attack the valve body from the inside out. You're right back where you started, but now with a false sense of security shattered.

The business consequences are severe. Beyond the obvious costs of valve replacement and production downtime, there are the critical risks of product contamination in high-purity applications (like semiconductors or pharmaceuticals) and the significant safety and environmental liability of a hazardous chemical leak.

The Real Point of Failure: It’s Not the Valve, It’s the Barrier

The frustration with these failures often leads people to believe that lined valves are inherently unreliable. But that's a misdiagnosis. The problem isn't the concept; it’s the execution.

The breakthrough realization is this: you don't need the entire valve to be made of an invincible material. You only need a perfect, impenetrable barrier separating the aggressive process media from the valve's structural body.

The Chemistry of an Unbeatable Shield

This is where PTFE (Polytetrafluoroethylene) comes in. Its molecular structure is built on incredibly strong carbon-fluorine bonds, one of the most stable chemical bonds known. This is not just marketing jargon; it’s fundamental chemistry. This bond makes PTFE inert to nearly everything, from brutal acids and alkalis to powerful solvents. It’s the closest thing to a universal chemical shield in industrial materials.

Why Generic Liners Can Be a Ticking Time Bomb

So if PTFE is so great, why do some lined valves fail? Because a liner is only as good as its manufacturing precision. A "good enough" liner can fail for several reasons that aren't immediately obvious:

- Inconsistent Thickness & Pinholes: Microscopic thin spots or voids in a poorly made liner become the first point of attack, allowing corrosive media to permeate and destroy the valve body.

- Deformation (Creep): A liner not properly engineered for the specific pressure and temperature of your application can deform or "creep" over time, causing the seal to fail.

- Improper Fit: If the liner isn't manufactured to exact tolerances, it can be damaged during installation or prevent the valve from closing properly, leading to immediate leaks.

The common solutions fail because they don't address this root cause. An exotic alloy valve is overkill, and a cheap standard valve is no defense at all. A generic lined valve ignores the fact that the quality of the liner is everything.

From Flawed Barrier to Perfect Seal: Engineering for Absolute Reliability

To truly solve the problem, you need to shift your focus from the valve to the liner itself. The goal is to secure a liner that is not just a coating, but a precision-engineered component designed for your exact application.

This is where the expertise in fluoropolymer fabrication becomes the most critical factor. The solution isn't just "a PTFE liner"; it's a liner that guarantees:

- Absolute Purity and Uniformity: Manufactured from the highest-grade virgin PTFE to ensure there are no weak points or pinholes.

- Dimensional Stability: Engineered to withstand your specific process temperatures and pressures without deforming, ensuring a tight seal for the life of the valve.

- Precision Tolerances: Fabricated to exact specifications so that it fits perfectly, functions flawlessly, and isn't compromised during installation.

KINTEK: The Expertise Inside the Industry's Most Reliable Valves

At KINTEK, we don't just supply parts; we engineer solutions. We specialize in the precision fabrication of high-performance PTFE components like the liners and seals that form the heart of corrosion-proof valves. We understand that in applications from semiconductor manufacturing to specialty chemical processing, "almost perfect" is the same as "failed."

Our process is built on a deep understanding of the root problem. We work with you to design and manufacture components that are custom-tailored to your media, temperatures, and pressures. By controlling every aspect of production, from material selection to final machining, we deliver the flawless barrier that turns a standard valve body into a fortress of chemical resistance.

Unlocking New Potential: When Corrosion Is No Longer a Constraint

Once you have a reliable, cost-effective strategy for handling corrosive media, it changes what's possible for your entire operation.

Instead of being limited by your infrastructure, you are empowered by it. You can confidently design larger-diameter lines without worrying about a million-dollar valve budget. You can push your process to higher temperatures or use more effective chemicals to improve yield and efficiency, knowing your equipment is protected. In high-purity industries, you can guarantee zero metallic contamination, leading to a higher quality final product and fewer rejected batches.

Ultimately, solving the valve problem frees up capital, reduces maintenance headaches, and allows your best minds to focus on innovation and growth, not just preventing the next failure.

Your challenges with corrosive fluids are unique. The solution should be too. Don't settle for an off-the-shelf component when your process demands precision. Let's talk about how a properly engineered PTFE solution can eliminate a chronic problem and unlock new levels of performance and profitability for your projects. Contact Our Experts to discuss your specific application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

Related Articles

- The Unseen Component: How PTFE Became the Bedrock of Medical Device Reliability

- When 'Chemically Inert' Isn't Enough: Why Your PTFE Components Fail and How to Prevent It

- The Engineer's Dilemma: Navigating the Trade-offs Between PTFE and Its Alternatives

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions