The Psychology of Component Failure

A multi-million dollar satellite, a deep-sea drilling rig, a life-saving medical analyzer. These systems are monuments to precision engineering. Yet, their operational integrity can hinge on a component costing a tiny fraction of the total: the seal.

When a conventional elastomeric seal fails, it's rarely a surprise to the material itself. It’s simply reached the physical limits of its design. The real problem is a psychological one for the engineer: relying on a component that has a built-in countdown clock, especially when exposed to heat, aggressive chemicals, or extreme pressure. This is the hidden vulnerability in countless critical systems.

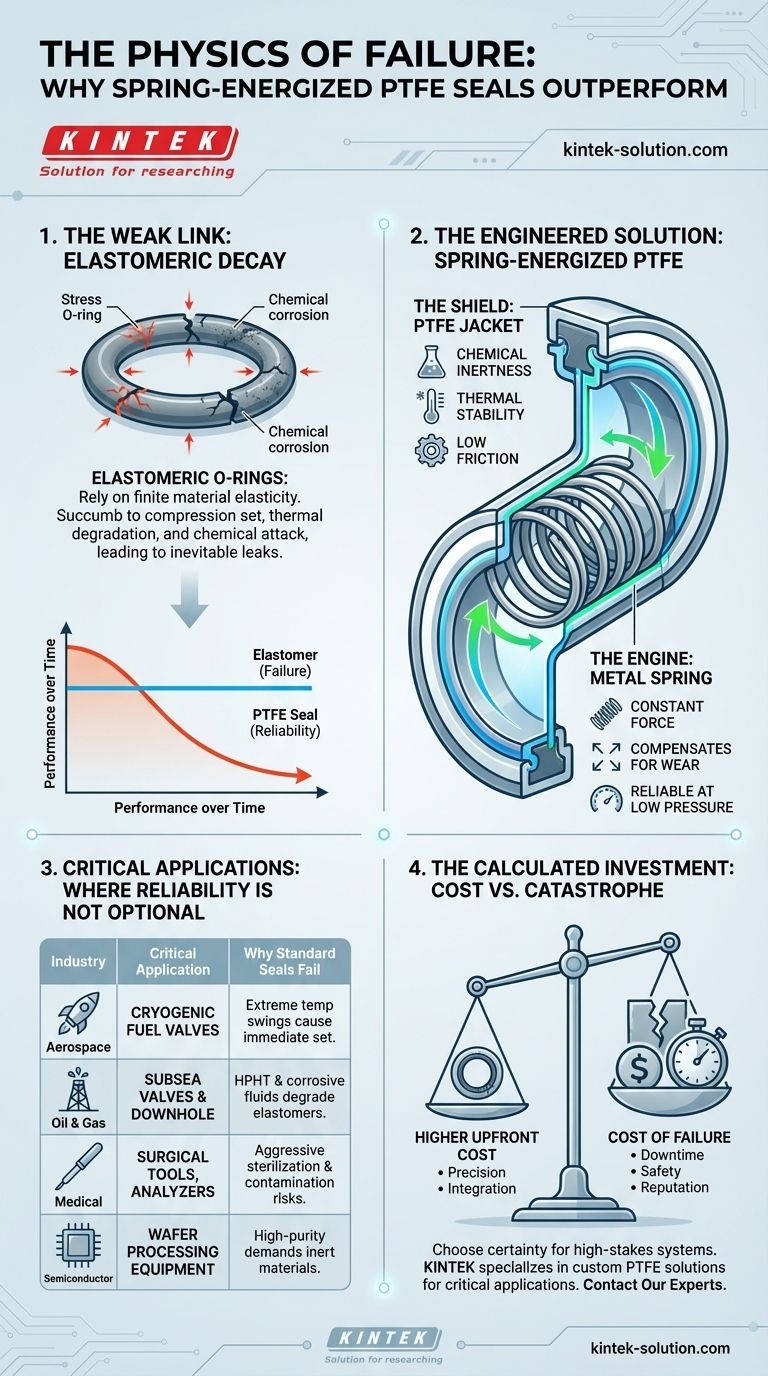

The Inevitable Decay of Elasticity

Standard seals, like O-rings, rely on their own material elasticity to create a barrier. When compressed, the material pushes back, filling the gap.

But this "memory" is finite.

Under thermal stress—from cryogenic lows to engine-high temperatures—elastomers permanently deform. This phenomenon, known as compression set, is the point of no return. The seal loses its ability to push back, a gap forms, and a leak begins. Aggressive chemicals accelerate this process, degrading the material and erasing its resilience.

This isn't a defect; it's the physics of the material. The challenge isn't to find a "better" rubber, but to re-engineer the source of the sealing force itself.

An Engineered Solution: Mechanical Force Meets Material Science

Spring-energized seals represent a fundamental shift in design philosophy. Instead of relying on fallible material memory, they create a permanent, active sealing force through a clever synergy of two components.

1. The Shield: The PTFE Jacket

The seal's outer body is a precision-machined jacket made from Polytetrafluoroethylene (PTFE). This material acts as the primary barrier, providing:

- Near-Universal Chemical Inertness: It remains indifferent to almost all industrial acids, solvents, and corrosive fluids that would destroy an elastomer.

- Extreme Thermal Stability: It performs reliably from cryogenic fuel lines to high-temperature engine compartments.

- Low Friction: In dynamic applications like pumps or actuators, its slick surface minimizes heat generation and wear, extending the life of the entire system.

2. The Engine: The Energizing Spring

The PTFE jacket itself is relatively rigid. The sealing force comes from a metal spring (like a V-spring or canted coil spring) embedded within it.

This spring is the heart of the system. It exerts a constant, unwavering mechanical force, pushing the PTFE lips against the sealing surfaces. It never gets tired, it doesn't take a compression set, and it actively compensates for:

- Wear: As the PTFE jacket slowly wears over millions of cycles, the spring expands to fill the gap.

- Temperature Fluctuations: It maintains a consistent force even as hardware expands or contracts.

- Low Pressure: It ensures a tight seal even when system pressure is too low to energize the seal on its own.

This design replaces temporary material elasticity with permanent mechanical energy.

Where Reliability Is Not Optional

This level of engineered resilience makes spring-energized PTFE seals the default solution in industries where the cost of failure is astronomical.

| Industry | Critical Application | Why a Standard Seal Fails |

|---|---|---|

| Aerospace & Defense | Cryogenic fuel valves, hydraulic actuators | Extreme temperature swings (-260°C to +260°C) cause immediate compression set. |

| Oil & Gas | Subsea valves, downhole drilling tools | High Pressure, High Temperature (HPHT) and corrosive fluids degrade elastomers. |

| Medical & Life Sciences | Surgical tools, liquid chromatography | Aggressive sterilization chemicals and the need for zero contamination rule out reactive materials. |

| Semiconductor | Wafer processing equipment, chemical pumps | High-purity processes and aggressive chemicals demand inert, non-leaching materials. |

The Calculus of Investment: Cost vs. Catastrophe

Objectively, a spring-energized seal has a higher upfront cost than a commodity O-ring. This isn't a simple trade-off; it's a calculated engineering decision.

- Precision Demands: PTFE is less forgiving than rubber. It requires a smoother hardware surface finish and a precisely machined gland designed specifically for the seal. This is not a drop-in replacement but part of an integrated system design.

- The True Cost: The initial cost must be weighed against the potential cost of failure: downtime, lost production, safety hazards, and reputational damage. When viewed through this lens, the seal becomes an insurance policy against catastrophic failure.

Choosing the right seal is a matter of aligning the solution with the severity of the problem.

- For moderate conditions and cost-sensitive applications, an elastomeric seal is often sufficient.

- For extreme temperatures, high pressures, aggressive media, or critical dynamic systems, relying on anything less than a spring-energized seal is introducing an unacceptable risk.

At KINTEK, we specialize in manufacturing the precision PTFE components that high-stakes industries rely on. From custom spring-energized seals to liners and labware, we understand that our components are integral to our customers' success. We work with engineering teams from prototype to high-volume production to ensure that every seal is a solution, not a potential problem.

When your system's integrity cannot be compromised, you need a component engineered for certainty. Contact Our Experts to discuss how our custom PTFE solutions can secure your most critical applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

Related Articles

- Why Your High-Performance PTFE Parts Fail—And Why It's Not the Material's Fault

- The Unseen Guardian: How PTFE's Molecular Shield Protects Our Most Critical Systems

- How PTFE Solves Critical Industrial Challenges Through Material Superiority

- When "Chemically Inert" Isn't Enough: The Hidden Cause of PTFE Component Failure

- The Physics of a Perfect Fit: How PTFE Eliminates an Athlete's Hidden Distractions