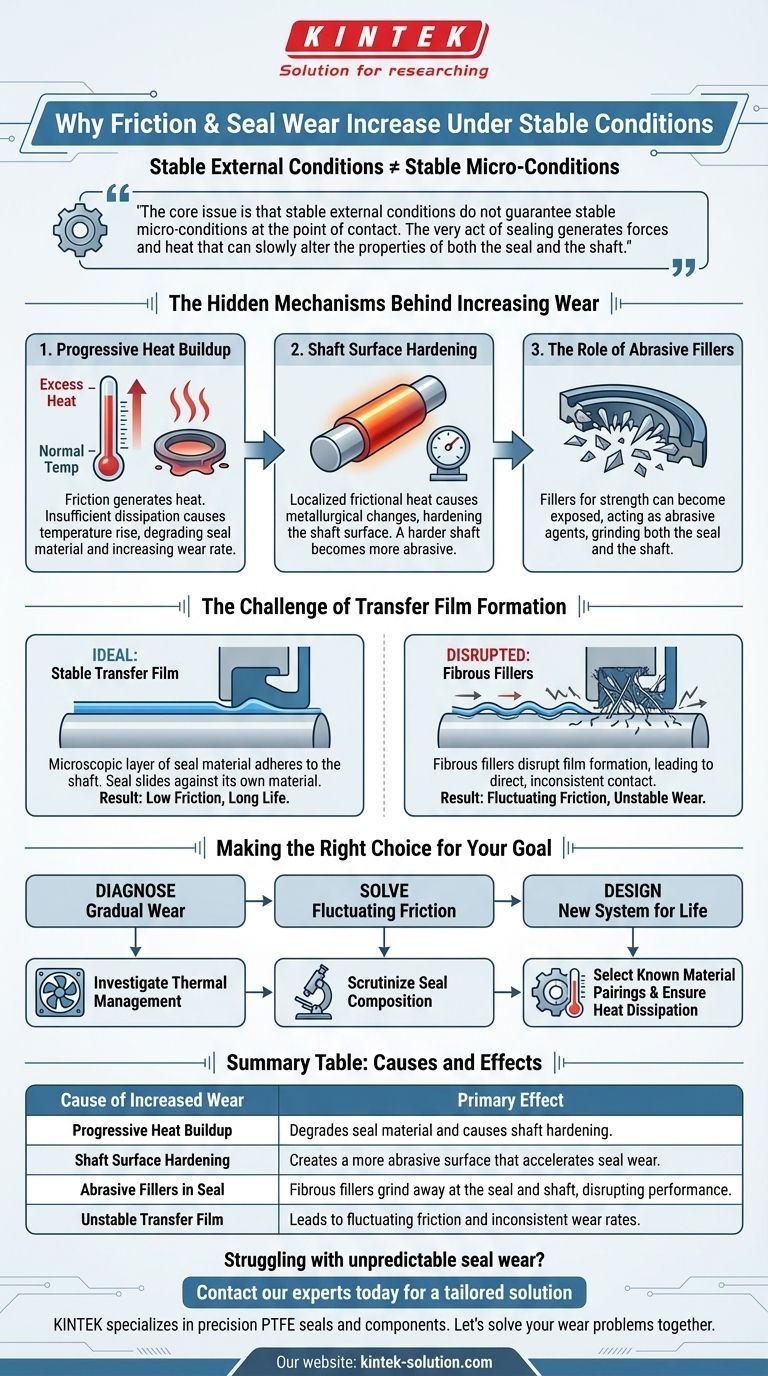

In short, friction and seal wear can increase over time, even under stable operating conditions, due to subtle changes at the sealing interface. The primary causes are progressive heat buildup, hardening of the shaft's surface from that heat, and the abrasive action of certain fillers within the seal material itself.

The core issue is that stable external conditions do not guarantee stable micro-conditions at the point of contact. The very act of sealing generates forces and heat that can slowly alter the properties of both the seal and the shaft, leading to a gradual increase in wear.

The Hidden Mechanisms Behind Increasing Wear

Even when speed, pressure, and temperature appear constant, the dynamic environment between the seal and the shaft is constantly evolving. Several factors can contribute to a negative feedback loop where friction and wear begin to accelerate.

Progressive Heat Buildup

All friction generates heat. If the system cannot dissipate this thermal energy faster than it is created, the temperature at the sealing interface will rise over time. This excess heat can degrade the seal material, reducing its effectiveness and increasing the rate of wear.

Shaft Surface Hardening

The constant frictional heat is not just a problem for the seal; it can also affect the shaft. This localized heating can cause metallurgical changes in the shaft material, a phenomenon known as surface hardening. A harder shaft surface can become more abrasive, accelerating the wear on the softer seal material.

The Role of Abrasive Fillers

Many high-performance seal materials contain fillers to enhance properties like strength and wear resistance. However, over time, some of these fillers can be exposed at the contact surface and act as an abrasive, grinding away at both the seal and the shaft.

The Challenge of Transfer Film Formation

The key to a long-lasting, low-friction seal is the creation of a stable and uniform transfer film. This is a microscopic layer of the seal material that adheres to the shaft surface, allowing the seal to slide against a layer of its own material rather than the bare shaft.

Why Some Materials Struggle

Certain additives, particularly fibrous fillers, can disrupt this critical process. While these fibers add strength and wear resistance to the seal composite, their structure can prevent the formation of a smooth, uniform transfer film.

The Consequence: Fluctuating Friction

Without a stable transfer film, the seal makes direct, inconsistent contact with the shaft. This leads to higher, fluctuating friction and an unstable wear rate. The system never reaches a state of equilibrium, and wear continues to increase as the sealing interface breaks down.

Making the Right Choice for Your Goal

Understanding these underlying mechanisms is key to diagnosing issues and selecting the right materials for long-term reliability.

- If your primary focus is diagnosing a gradual increase in wear: Investigate thermal management first, as insufficient heat dissipation is a common cause of both seal degradation and shaft hardening.

- If your primary focus is solving fluctuating or unpredictable friction: Scrutinize the seal material's composition, as fibrous or abrasive fillers are likely preventing the formation of a stable transfer film.

- If your primary focus is designing a new system for maximum life: Select seal and shaft material pairings known to create a uniform transfer film and ensure the design allows for adequate heat dissipation from the contact zone.

Ultimately, recognizing that the sealing interface is a dynamic system is the first step toward achieving long-term, stable performance.

Summary Table:

| Cause of Increased Wear | Primary Effect |

|---|---|

| Progressive Heat Buildup | Degrades seal material and causes shaft hardening. |

| Shaft Surface Hardening | Creates a more abrasive surface that accelerates seal wear. |

| Abrasive Fillers in Seal | Fibrous fillers grind away at the seal and shaft, disrupting performance. |

| Unstable Transfer Film | Leads to fluctuating friction and inconsistent wear rates. |

Struggling with unpredictable seal wear? The root cause often lies in material compatibility and thermal management. At KINTEK, we specialize in manufacturing precision PTFE seals and components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your seals are engineered for stable transfer film formation and long-term reliability. Let's solve your wear problems together. Contact our experts today for a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the core material options for PTFE encapsulated O-rings? Choose Viton® or Silicone for Your Sealing Needs

- What are the key properties of PTFE and nylon in bushings and thrust washers? Select the Right Material for Your Application

- What are the limitations of POM as a ball valve seat material? Key Risks & Safer Alternatives

- What are PTFE washers and what are their key properties? Specialized Seals for Extreme Conditions

- What industries commonly use Teflon encapsulated O-rings for chemical resistance? Protect Critical Processes from Corrosion

- How are PTFE rubber seals utilized in the chemical processing industry? Ensuring Leak-Free Safety in Corrosive Environments

- What are the key properties of PTFE pipes? Unlock Unmatched Chemical & Thermal Resistance

- What are the three basic types of Teflon back-up rings? Choose the Right Design for Your Sealing System