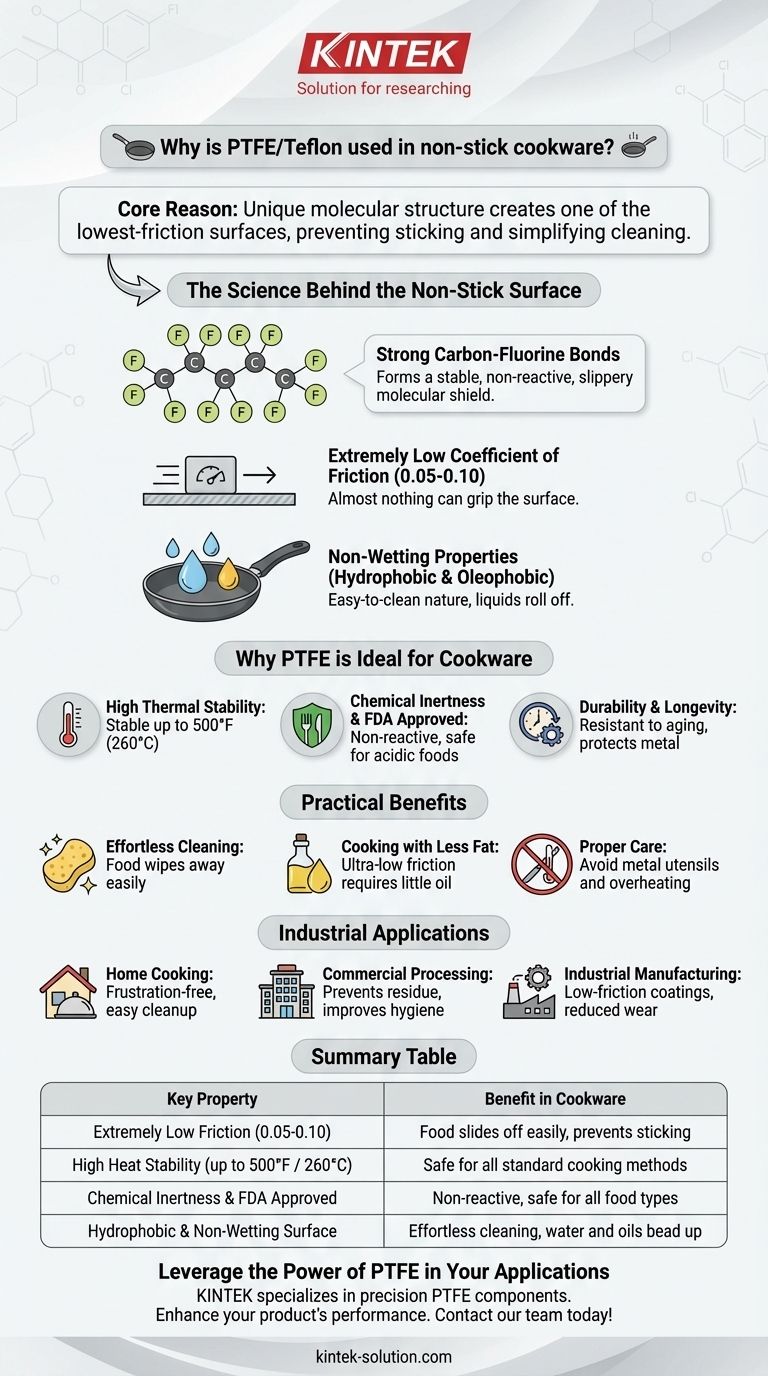

At its core, Polytetrafluoroethylene (PTFE), commercially known as Teflon, is used in non-stick cookware because its unique molecular structure creates one of the lowest-friction surfaces of any known solid material. This property, combined with its high heat tolerance and chemical stability, makes it exceptionally effective at preventing food from sticking during cooking and drastically simplifies cleaning.

The true reason for PTFE's effectiveness lies in its powerful carbon-fluorine bonds. These bonds form a stable, non-reactive, and extremely "slippery" molecular shield that prevents other materials, like food, from forming a chemical connection with the pan's surface.

The Science Behind the Non-Stick Surface

To understand why PTFE works so well, we need to look at its fundamental chemical structure. The material's properties are not accidental; they are a direct result of its atomic arrangement.

The Carbon-Fluorine Bond

PTFE is a polymer, a long chain of repeating molecules. Its backbone is made of carbon atoms, but each carbon atom is completely surrounded and protected by fluorine atoms.

The bond between carbon and fluorine is incredibly strong and stable. This creates a dense, non-porous sheath of fluorine atoms that is chemically inert, meaning it doesn't readily react with other substances.

An Extremely Low Coefficient of Friction

This molecular structure gives PTFE a coefficient of friction between 0.05 and 0.10, one of the lowest recorded for any solid.

Essentially, this means almost nothing can get a grip on the surface. Food simply slides across it rather than bonding to it.

Non-Wetting Properties

The same energy that repels food also repels liquids. Water and oils bead up and roll off a PTFE surface instead of spreading out. This "non-wetting" or hydrophobic characteristic is a key contributor to its easy-to-clean nature.

Why PTFE is Ideal for Cookware

While being non-stick is the primary requirement, a material must have other specific characteristics to be safe and effective in the high-heat, high-stress environment of a kitchen.

High Thermal Stability

PTFE is effective across a wide temperature range, remaining stable from -325 °F up to +500 °F (-198 °C to +260 °C). This window comfortably covers all typical cooking temperatures, ensuring the coating does not break down during normal use.

Chemical Inertness and Food Safety

Because of its stable molecular structure, PTFE is non-reactive. It won't corrode, rust, or react with acidic foods like tomatoes or lemon juice.

This stability is also why it is certified as food-grade by the FDA. It does not impart any taste or chemicals into the food when used as directed.

Durability and Longevity

Beyond its primary features, PTFE is resistant to embrittlement and aging. It is also waterproof, providing a layer of corrosion resistance for the metal pan underneath, which extends the cookware's useful life.

Practical Benefits and Considerations

The scientific properties of PTFE translate directly into tangible benefits for the user, but they also imply certain best practices for care.

Effortless Cleaning

The most obvious benefit is the ease of cleaning. Since food residue cannot form a strong bond with the pan's surface, it wipes away with minimal effort, reducing scrubbing and soaking time.

Cooking with Less Fat

The ultra-low friction surface allows for cooking with little to no oil or butter. This is a significant advantage for those seeking to reduce fat consumption without sacrificing the cooking experience.

Importance of Proper Care

The PTFE coating is a surface layer. To maintain its integrity, it's crucial to avoid using metal utensils that can scratch it and to avoid overheating the pan beyond its recommended temperature, which can cause the coating to degrade.

How This Applies to Your Goal

The unique properties of PTFE make it valuable not just in the kitchen but in many industrial settings where preventing adhesion is critical.

- If your primary focus is home cooking: PTFE provides reliable food release for a frustration-free cooking experience and dramatically simplifies cleanup.

- If your primary focus is commercial food processing: The non-stick surface prevents residue buildup on bakeware and machinery, improving operational efficiency and hygiene.

- If your primary focus is industrial manufacturing: PTFE's low-friction properties are used in self-lubricating bearings and surface coatings to reduce product adhesion and wear on equipment.

Ultimately, PTFE's simple yet robust molecular design solves the universal problem of unwanted sticking across a vast range of applications.

Summary Table:

| Key Property | Benefit in Cookware |

|---|---|

| Extremely Low Friction (0.05-0.10) | Food slides off easily, prevents sticking |

| High Heat Stability (up to 500°F / 260°C) | Safe for all standard cooking methods |

| Chemical Inertness & FDA Approved | Non-reactive, safe for all food types |

| Hydrophobic & Non-Wetting Surface | Effortless cleaning, water and oils bead up |

Leverage the Power of PTFE in Your Applications

PTFE's exceptional non-stick and high-performance properties extend far beyond the kitchen. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

Whether you need a standard part or a custom-fabricated solution from prototype to high-volume production, our expertise ensures a perfect fit for your demanding requirements.

Enhance your product's performance and reliability—contact our team today to discuss your PTFE needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance