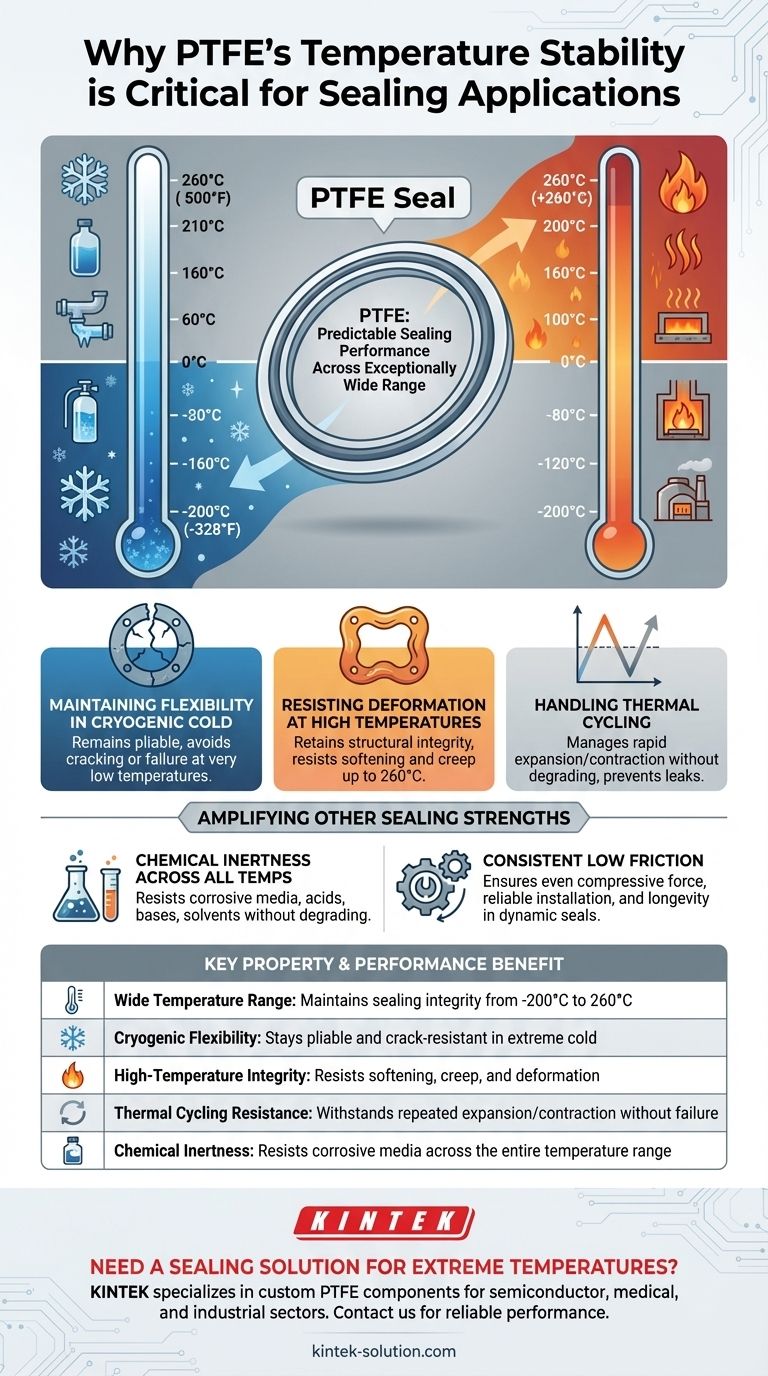

At its core, PTFE's temperature stability is critical because it ensures the material maintains its essential physical sealing properties across an exceptionally wide operational range, from -200°C to 260°C. Where other materials would become brittle, melt, or deform, PTFE remains flexible and structurally sound, guaranteeing a consistent, leak-proof seal in environments with extreme or fluctuating temperatures.

The true value of PTFE's thermal stability isn't just its ability to survive extreme temperatures, but its capacity to deliver predictable sealing performance under those conditions. It ensures the seal you install at room temperature behaves the same way in cryogenic cold or high heat.

The Foundation of a Reliable Seal: Consistent Physical Properties

A sealant's primary job is to fill a gap and prevent leaks. Its ability to do this depends entirely on its physical properties. PTFE's distinction is its ability to keep these properties consistent when temperatures swing dramatically.

Maintaining Flexibility in Cryogenic Cold

Many polymers become rigid and brittle at very low temperatures, causing them to crack under pressure or vibration. This leads to catastrophic seal failure.

PTFE, however, remains flexible and pliable even in cryogenic conditions (-200°C). This allows it to conform to surface imperfections and maintain sealing pressure without fracturing.

Resisting Deformation at High Temperatures

As temperatures rise, other sealing materials can soften, creep, or even melt. This causes them to lose their shape and sealing force, resulting in leaks.

PTFE maintains its structural integrity and form up to its continuous service temperature of 260°C (500°F). This resistance to heat-induced deformation is vital in high-temperature industrial, automotive, and aerospace applications.

Handling Thermal Cycling Without Failure

Many systems, especially in aerospace and chemical processing, experience rapid temperature fluctuations. This thermal cycling forces materials to expand and contract repeatedly.

PTFE’s stability allows it to manage this cycling without degrading or losing its seal. It reliably returns to its original form, preventing leaks that would occur as gaps open and close between components.

How Temperature Stability Amplifies PTFE's Other Sealing Strengths

PTFE's thermal performance does not exist in isolation. It works in concert with its other unique characteristics, making the combination exceptionally powerful for sealing.

Chemical Inertness Across All Temperatures

PTFE is famous for its resistance to nearly all acids, bases, and solvents. Crucially, this chemical inertness is maintained across its entire temperature range.

This means a PTFE seal will not degrade when sealing a hot, corrosive chemical, a scenario that would quickly destroy less stable materials.

Consistent Low Friction

PTFE has one of the lowest coefficients of friction of any solid. This property ensures that when a joint is tightened, the compressive force is applied evenly without twisting or tearing the gasket.

Because this low friction is stable with temperature, installation is more reliable, and performance in dynamic sealing applications remains consistent, preventing wear and premature failure.

Reliable Performance Under Load

Seals and gaskets must resist being permanently crushed or deformed under the load of the components they are sealing. PTFE exhibits minimal deformation under load.

Its thermal stability ensures it can withstand this pressure without failing, whether the application is at room temperature or 200°C.

Understanding the Trade-offs

While exceptionally capable, no material is without limitations. Objectively understanding these is key to proper application.

The Challenge of Creep (Cold Flow)

Despite its good performance under load, PTFE can be susceptible to "creep" or "cold flow"—a slow, gradual deformation under sustained pressure over a long period.

In high-load static applications, this can eventually reduce sealing pressure. This is often mitigated by using filled grades of PTFE, which incorporate materials like glass, carbon, or bronze to enhance creep resistance.

Mechanical Strength Considerations

PTFE is a relatively soft material. While this helps it conform to surfaces, it lacks the high tensile strength of metals or some engineered plastics.

For extremely high-pressure systems, PTFE may need to be used in specifically designed seals or be reinforced with other materials to prevent extrusion.

Making the Right Choice for Your Application

Selecting a sealing material requires matching its properties to the demands of the environment. PTFE's unique profile makes it a definitive choice for specific challenges.

- If your primary focus is extreme temperature environments: PTFE's unparalleled operational range from cryogenic to high heat makes it a default choice for reliable sealing where others fail.

- If your primary focus is aggressive chemical processing: Its combination of thermal stability and near-total chemical inertness ensures a long-lasting, leak-proof seal for corrosive media.

- If your primary focus is dynamic or high-vibration systems: The consistent low friction and flexibility, maintained across all temperatures, ensure seal longevity and prevent premature wear.

Ultimately, choosing PTFE is choosing predictable, reliable sealing performance when environmental conditions are anything but predictable.

Summary Table:

| Key Property | Performance Benefit |

|---|---|

| Wide Temperature Range | Maintains sealing integrity from -200°C to 260°C |

| Cryogenic Flexibility | Stays pliable and crack-resistant in extreme cold |

| High-Temperature Integrity | Resists softening, creep, and deformation |

| Thermal Cycling Resistance | Withstands repeated expansion/contraction without failure |

| Chemical Inertness | Resists corrosive media across the entire temperature range |

Need a Sealing Solution for Extreme Temperatures?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your seals deliver reliable, leak-proof performance, whether you're facing cryogenic conditions or high-heat environments.

We offer custom fabrication from prototypes to high-volume orders, tailoring PTFE's exceptional thermal stability to your exact application requirements.

Contact KINTEK today to discuss your specific sealing challenges and get a solution that guarantees performance when temperatures are anything but stable.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the primary characteristics of PTFE seals? Unmatched Performance for Extreme Conditions

- What are the key steps for properly installing PTFE gaskets? Ensure a leak-free seal with our expert guide.

- What are some general applications of PTFE with fillers? Enhance Performance in Demanding Seals & Bearings

- What are the advantages of reinforced PTFE (RPTFE) and TFM? Solve PTFE's Cold Flow Problem

- What are the aerospace applications of precision-machined PTFE parts? Achieve Peak Performance in Harsh Environments

- What are the main advantages of PTFE processing machines? Achieve Superior Component Performance

- Are expanded PTFE gaskets as durable as standard PTFE gaskets? Discover the Best Choice for Your Seal.

- How does modified PTFE differ from virgin PTFE? Unlock Superior Performance for Demanding Applications