To put it simply, Polytetrafluoroethylene (PTFE) is a cornerstone material in modern laboratories primarily because of its extreme chemical resistance and non-contaminating surface. This unique combination allows it to handle the most aggressive chemicals and sensitive biological samples without reacting, degrading, or introducing impurities, thereby preserving the integrity of experimental results.

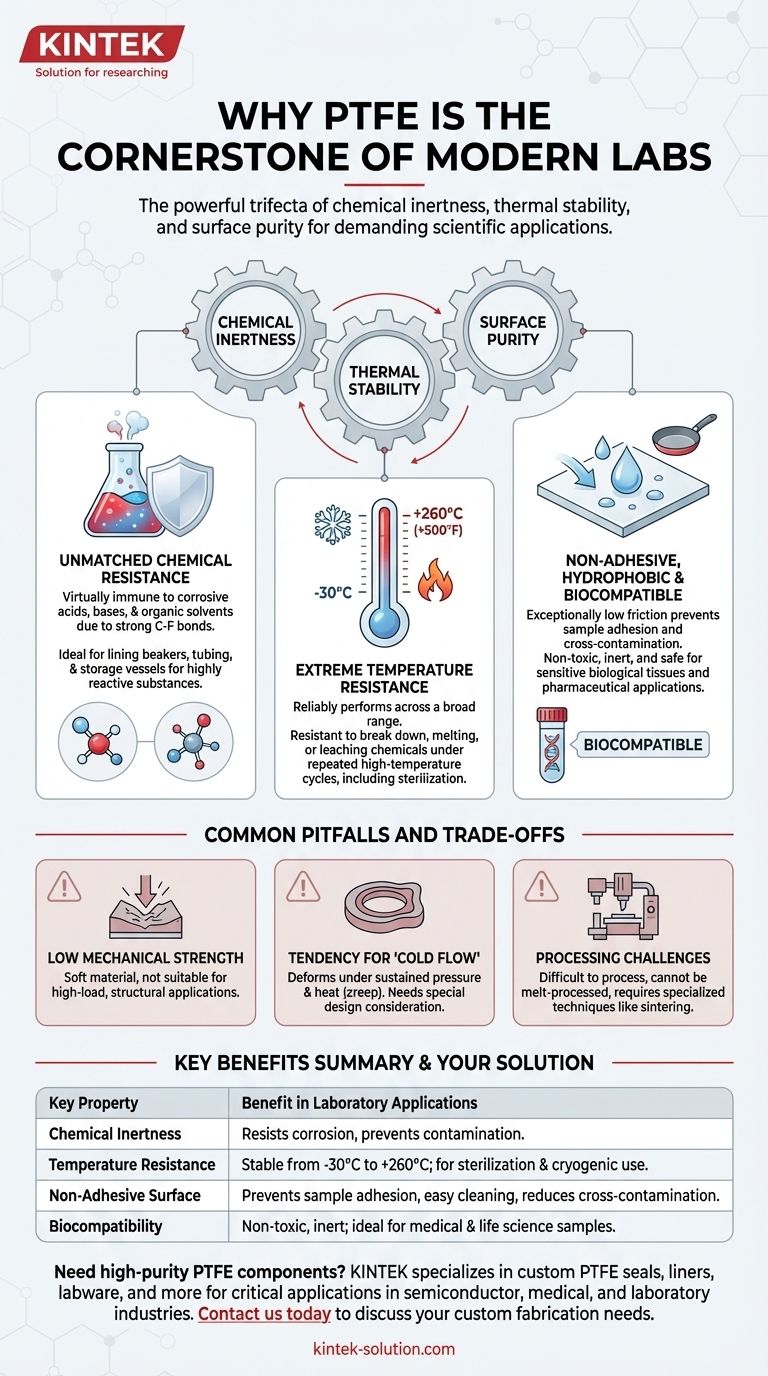

The core reason for PTFE's widespread adoption isn't a single property, but its powerful trifecta of chemical inertness, thermal stability, and surface purity. This makes it one of the most reliable and non-reactive materials available for demanding scientific applications.

The Core Pillars of PTFE's Utility in the Lab

To understand why PTFE is so indispensable, we must look at its fundamental material properties. Each one directly solves a common and critical challenge faced in a laboratory environment.

Unmatched Chemical Inertness

PTFE is virtually immune to attack from the vast majority of chemicals, including highly corrosive acids, bases, and organic solvents.

This inertness is due to the incredibly strong carbon-fluorine bonds that make up its molecular structure.

Consequently, PTFE is used to construct or line beakers, tubing, piping, and storage vessels that will contain highly reactive substances without risk of corrosion or contamination.

Extreme Temperature Resistance

Scientific procedures often involve a wide range of temperatures, from cryogenic freezing to high-heat sterilization.

PTFE performs reliably across a broad operating temperature range, typically from -30°C up to +260°C (+500°F) for continuous use, with a melting point around 327°C (621°F).

This thermal stability ensures that equipment made from PTFE will not break down, melt, or leach chemicals when exposed to repeated high-temperature cycles.

Non-Adhesive and Hydrophobic Properties

The surface of PTFE is famously non-stick and water-repellent (hydrophobic). It has one of the lowest coefficients of friction of any solid material.

In practice, this means that liquids and samples bead up and slide off easily, preventing valuable material from adhering to container walls.

This property is critical for ensuring accurate measurements and preventing cross-contamination between experiments, as surfaces are exceptionally easy to clean and leave no residue.

Purity and Biocompatibility

For medical, pharmaceutical, and life science research, the material contacting a sample must not interfere with it.

PTFE is non-toxic, inert, and highly biocompatible, meaning it does not cause adverse reactions when in contact with biological tissues or sensitive organic compounds.

This makes it an ideal material for medical devices like catheters and syringes, seals for pharmaceutical vials, and bio-containment vessels where purity is non-negotiable.

Common Pitfalls and Trade-offs

While its properties are exceptional, PTFE is not the solution for every problem. Understanding its limitations is key to using it effectively.

Low Mechanical Strength

PTFE is a relatively soft material compared to metals or even other engineering plastics. It is not suitable for high-load, structural applications where rigidity is required.

Tendency for "Cold Flow"

Under sustained pressure, especially at elevated temperatures, PTFE can slowly deform over time. This phenomenon, known as creep or cold flow, must be accounted for when designing long-term seals or high-pressure fittings.

Processing Challenges

The same inertness that makes PTFE so valuable also makes it difficult to process. It cannot be melt-processed like common plastics and often requires specialized techniques like sintering, which can increase manufacturing costs.

Making the Right Choice for Your Goal

Selecting the right material is a critical decision that directly impacts the validity of your work. Use PTFE when your experiment's integrity is the top priority.

- If your primary focus is handling highly corrosive reagents: PTFE's unparalleled chemical resistance makes it the safest and most reliable choice.

- If your primary focus is preventing sample cross-contamination: Its non-stick, hydrophobic surface ensures maximum sample recovery and purity between tests.

- If your primary focus is biocompatibility for medical or life science work: PTFE's non-toxic and inert nature provides a safe and non-reactive contact surface for sensitive biologicals.

Ultimately, choosing PTFE is a decision to prioritize chemical purity and experimental reliability above all other factors.

Summary Table:

| Key Property | Benefit in Laboratory Applications |

|---|---|

| Chemical Inertness | Resists corrosion from acids, bases, and solvents; prevents contamination. |

| Temperature Resistance | Stable from -30°C to +260°C; suitable for sterilization and cryogenic use. |

| Non-Adhesive Surface | Prevents sample adhesion, ensures easy cleaning, and reduces cross-contamination. |

| Biocompatibility | Non-toxic and inert; ideal for medical, pharmaceutical, and life science samples. |

Need high-purity PTFE components for your critical applications?

At KINTEK, we specialize in manufacturing custom PTFE seals, liners, labware, and more for semiconductor, medical, laboratory, and industrial industries. Our precision production ensures your equipment handles aggressive chemicals and sensitive samples with unmatched reliability.

Contact us today to discuss your custom fabrication needs—from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the safety features of PTFE-lined bottle caps? Ensure Chemical Inertness and Sample Integrity

- What types of labware or tools are commonly made from PTFE? Essential Chemically-Resistant Equipment for Your Lab

- What are the key features of PTFE-lined bottle caps? Ensure Chemical Integrity and Purity for Your Samples

- What are the key features of PTFE reagent bottles? Superior Chemical Resistance and Durability

- What types of PTFE liners are available for bottle caps? Choose Between Solid PTFE or Composite Liners

- What are the primary applications of PTFE syringe filters in laboratories? Ensure Sample Purity & Protect Sensitive Instruments

- How does temperature stability affect the choice of a PTFE-coated septum? Ensure Accurate Chromatographic Results

- What other PTFE lab accessories are commonly used? Essential Tools for Chemical Resistance & Purity