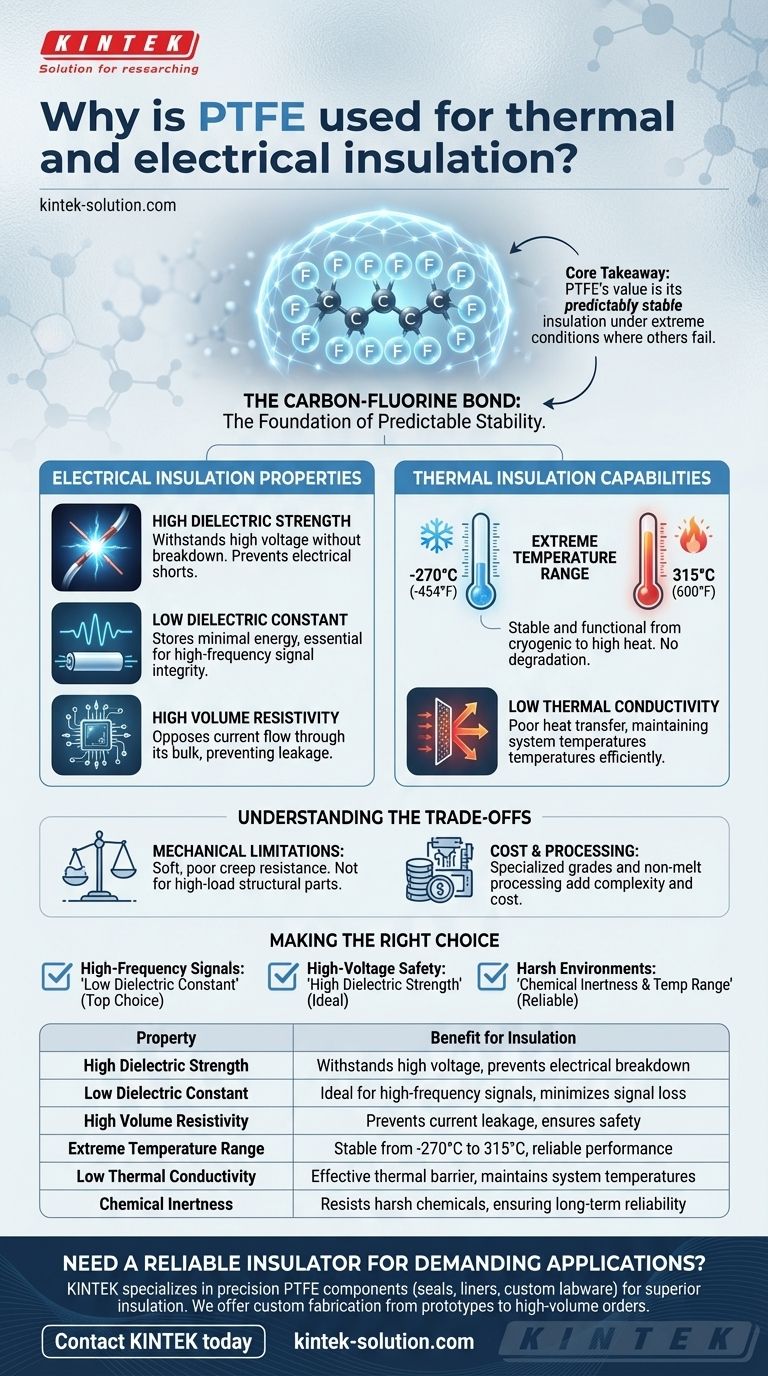

The fundamental reason PTFE is an exceptional thermal and electrical insulator lies in its unique molecular structure. The incredibly strong and stable bonds between its carbon and fluorine atoms create a material that is chemically inert, non-conductive, and maintains its integrity across an extreme range of temperatures.

The core takeaway is that PTFE's value isn't just in being an insulator; it's in being a predictably stable insulator. It performs reliably under conditions—high voltage, high frequencies, extreme temperatures, and harsh chemicals—where lesser materials would fail.

The Molecular Basis for PTFE's Stability

The Carbon-Fluorine Bond

The bond between carbon and fluorine is one of the strongest known in organic chemistry. This creates a molecule that is exceptionally stable and non-reactive.

Fluorine atoms form a tight, uniform sheath around the carbon backbone. This protective sheath prevents other chemicals from reacting with the carbon chain and shields it from thermal energy.

Unpacking its Electrical Insulation Properties

PTFE is a premier choice for demanding electrical applications because it combines several critical insulating characteristics.

High Dielectric Strength

Dielectric strength measures a material's ability to withstand high voltage without breaking down and allowing current to flow.

PTFE has a very high dielectric strength, making it ideal for insulating high-voltage wires, cables, and connectors, effectively preventing electrical shorts and arcing.

Low Dielectric Constant

The dielectric constant indicates how much electrical energy a material can store in an electric field. A low value is essential for high-frequency applications.

Because PTFE stores very little energy, it minimizes signal loss in high-frequency cables and components, ensuring signal integrity in telecommunications and advanced electronics.

High Volume Resistivity

This property measures how strongly a material opposes the flow of electric current through its bulk. PTFE's high resistivity ensures almost no current leakage, protecting sensitive components and ensuring safety.

Analyzing its Thermal Insulation Capabilities

While known for electrical properties, PTFE is also an effective thermal insulator due to its inherent stability across a wide temperature spectrum.

An Extreme Operating Temperature Range

PTFE remains functional and stable from cryogenic temperatures (-454°F / -270°C) up to high-heat applications (600°F / 315°C).

This consistency means its insulating properties do not degrade when exposed to extreme process temperatures, a critical factor in industrial and aerospace settings.

Low Thermal Conductivity

PTFE does not transfer heat well. This property is why components like gaskets made from PTFE do not heat up significantly, helping to maintain stable temperatures within a system.

Understanding the Trade-offs

No material is perfect. Acknowledging PTFE's limitations is key to using it effectively.

Mechanical Limitations

PTFE is a relatively soft material with poor resistance to "creep," meaning it can deform over time when under a sustained load. This makes it unsuitable for high-load structural components without reinforcement.

Cost and Processing

Standard PTFE is common, but specialized grades formulated for even higher insulation or mechanical properties can be significantly more expensive.

Furthermore, PTFE cannot be processed with conventional melt-extrusion or molding techniques used for most thermoplastics, which can add to manufacturing complexity and cost.

Making the Right Choice for Your Application

To determine if PTFE is the correct choice, align its strengths with your primary goal.

- If your primary focus is high-frequency signal integrity: PTFE is a top choice due to its exceptionally low dielectric constant.

- If your primary focus is high-voltage safety and containment: Its high dielectric strength makes it ideal for preventing electrical breakdown.

- If your primary focus is insulation in a harsh environment: PTFE's unmatched chemical inertness and vast temperature range ensure reliability where other materials would corrode or degrade.

Ultimately, PTFE is the definitive material when you need consistent insulating performance under the most challenging conditions.

Summary Table:

| Property | Benefit for Insulation |

|---|---|

| High Dielectric Strength | Withstands high voltage, prevents electrical breakdown |

| Low Dielectric Constant | Ideal for high-frequency signals, minimizes signal loss |

| High Volume Resistivity | Prevents current leakage, ensures safety |

| Extreme Temperature Range | Stable from -270°C to 315°C, reliable performance |

| Low Thermal Conductivity | Effective thermal barrier, maintains system temperatures |

| Chemical Inertness | Resists harsh chemicals, ensuring long-term reliability |

Need a Reliable Insulator for Demanding Applications?

PTFE's predictable stability under extreme conditions makes it the definitive choice for critical components in the semiconductor, medical, laboratory, and industrial sectors.

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—that deliver superior insulation performance. We offer custom fabrication from prototypes to high-volume orders, ensuring your components meet exact specifications for even the most challenging environments.

Contact KINTEK today to discuss how our PTFE solutions can enhance the safety and reliability of your products.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the different grades of PTFE used in rotary shaft seals? Choose the Right Filler for Peak Performance

- What are the limitations when machining Teflon/PTFE? Overcome Dimensional Instability & Creep

- What are the key benefits of PTFE (Teflon) gaskets? Superior Chemical & Temperature Resistance

- Are PTFE flange gaskets customizable? Tailor Your Sealing Solution for Peak Performance

- What are the common issues hindering the adoption of PTFE wear plates? Overcome These 4 Key Barriers

- What configurations are available for PTFE rotary shaft seals? Optimize Performance with Lip, Shell & Material Options

- Why is a Teflon sheet essential for heat transfer projects? Ensure Perfect, Non-Stick Results

- How does PTFE rod function in electrical applications? Unmatched Insulation for Extreme Conditions