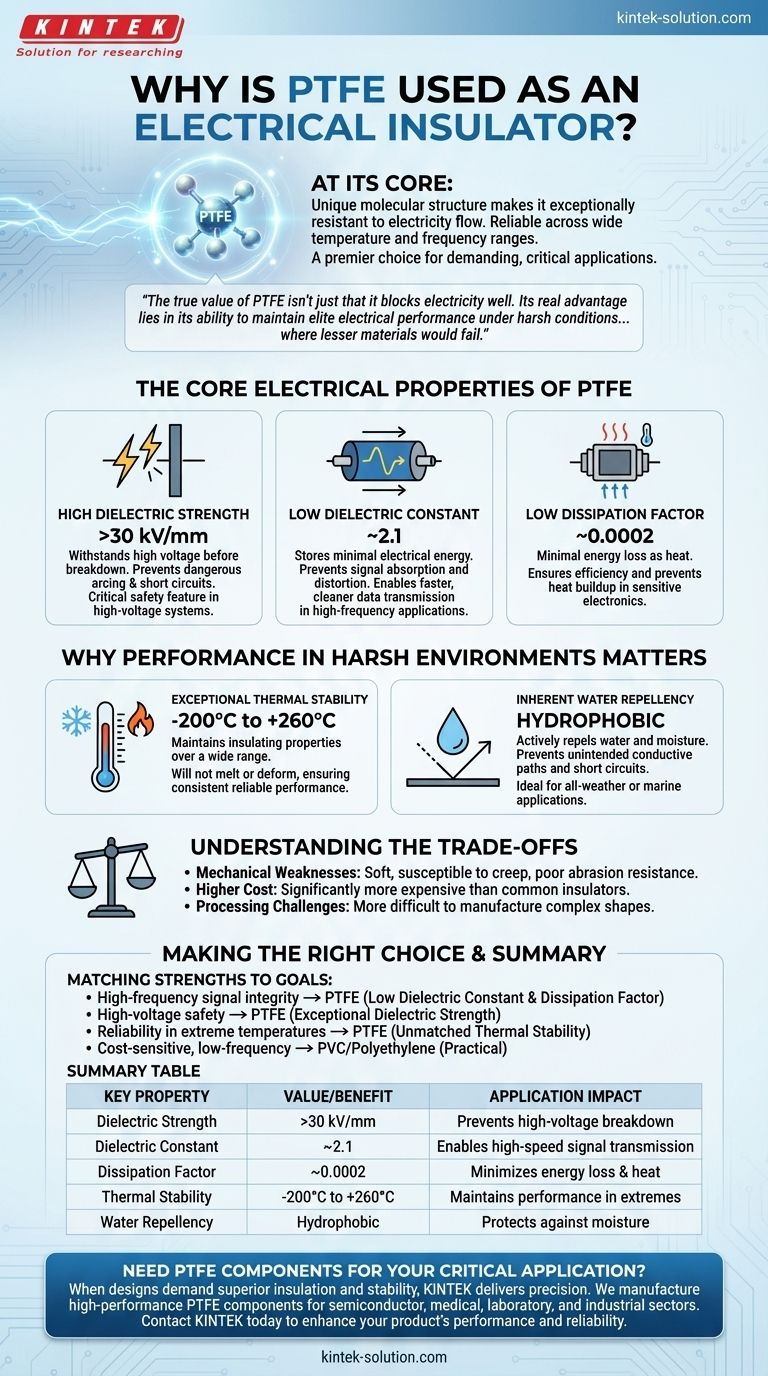

At its core, Polytetrafluoroethylene (PTFE) is used as an electrical insulator because its unique molecular structure makes it exceptionally resistant to the flow of electricity. This inherent resistance is complemented by its ability to perform reliably across a wide range of temperatures and frequencies, making it a premier choice for demanding electronic and high-voltage applications where safety and signal integrity are critical.

The true value of PTFE isn't just that it blocks electricity well. Its real advantage lies in its ability to maintain elite electrical performance under harsh conditions—from high frequencies to extreme temperatures—where lesser materials would fail.

The Core Electrical Properties of PTFE

The insulating capability of PTFE is not a single feature but a combination of three distinct electrical properties that make it uniquely effective.

High Dielectric Strength

Dielectric strength measures a material's ability to withstand a high voltage before it breaks down and allows current to pass. PTFE has an extremely high dielectric strength, often exceeding 30 kV/mm.

This means a very thin layer of PTFE can insulate against a very high voltage, preventing dangerous electrical arcing and short circuits. This is a critical safety feature in high-voltage wiring, cables, and connectors.

Low Dielectric Constant

The dielectric constant indicates how much electrical energy a material can store in an electric field. PTFE has a very low dielectric constant of 2.1.

For high-frequency applications like coaxial cables or printed circuit boards (PCBs), this is vital. A low dielectric constant ensures that the insulator does not absorb and distort the signal, enabling faster and cleaner data transmission with minimal signal loss.

Low Dissipation Factor

The dissipation factor, or loss tangent, measures how much energy is lost as heat within the insulating material. PTFE’s dissipation factor is exceptionally low (around 0.0002).

This minimal energy loss is crucial for efficiency and preventing heat buildup. In sensitive electronics, low dissipation ensures that components remain cool and that the integrity of the electrical signal is preserved.

Why Performance in Harsh Environments Matters

An insulator is only as good as its ability to perform in its intended environment. PTFE excels here, maintaining its properties under conditions that would degrade other materials.

Exceptional Thermal Stability

PTFE maintains its excellent insulating properties over an incredibly wide temperature range. It remains stable and effective from cryogenic temperatures up to its high melting point.

This means that even as components heat up during operation, the PTFE insulation will not melt, deform, or lose its ability to insulate, ensuring consistent and reliable performance.

Inherent Water Repellency

PTFE is hydrophobic, meaning it actively repels water. Moisture is a primary cause of electrical failure, as it can create unintended conductive paths and lead to short circuits.

By preventing water absorption, PTFE protects electrical components from humidity and direct water contact, making it ideal for use in all-weather or marine applications.

Understanding the Trade-offs

While PTFE is an elite insulator, it is not the solution for every problem. Objective technical decisions require understanding its limitations.

Mechanical Weaknesses

PTFE is a relatively soft material. It is susceptible to creep (cold flow under pressure) and has poor resistance to abrasion. It is not a structurally rigid material and requires mechanical support in many applications.

Higher Cost

Compared to common insulators like PVC or Polyethylene, PTFE is significantly more expensive. Its use is typically justified only when its superior performance in high-frequency, high-temperature, or high-voltage scenarios is a strict requirement.

Processing Challenges

PTFE can be more difficult to process and manufacture into complex shapes than other thermoplastics. This can add to the overall cost and complexity of the final component.

Making the Right Choice for Your Application

Selecting an insulator requires matching the material's strengths to your primary goal.

- If your primary focus is high-frequency signal integrity (e.g., data cables, PCBs): PTFE is the superior choice due to its extremely low dielectric constant and dissipation factor.

- If your primary focus is high-voltage safety (e.g., industrial wiring): PTFE's exceptional dielectric strength provides a robust and reliable barrier against electrical breakdown.

- If your primary focus is reliability in extreme temperatures: PTFE's unmatched thermal stability ensures its electrical properties will not degrade under heat or cold.

- If your primary focus is cost-sensitive, low-frequency applications: A more common material like PVC or polyethylene may be a more practical and economical choice.

Ultimately, choosing PTFE is an investment in unparalleled reliability for applications where electrical performance cannot be compromised.

Summary Table:

| Key Property | Value/Benefit | Application Impact |

|---|---|---|

| Dielectric Strength | >30 kV/mm | Prevents electrical breakdown in high-voltage systems |

| Dielectric Constant | ~2.1 | Enables high-speed, low-loss signal transmission |

| Dissipation Factor | ~0.0002 | Minimizes energy loss and heat generation |

| Thermal Stability | -200°C to +260°C | Maintains performance in extreme temperatures |

| Water Repellency | Hydrophobic | Protects against moisture and humidity |

Need PTFE Components for Your Critical Application?

When your designs demand the superior electrical insulation and thermal stability of PTFE, KINTEK delivers precision. We manufacture high-performance PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

Our expertise ensures your components meet stringent requirements for high-frequency, high-voltage, and extreme-temperature environments. From initial prototypes to high-volume production, we provide reliable, custom-fabricated solutions that protect your equipment and ensure signal integrity.

Contact KINTEK today to discuss your project requirements and discover how our PTFE expertise can enhance your product's performance and reliability.

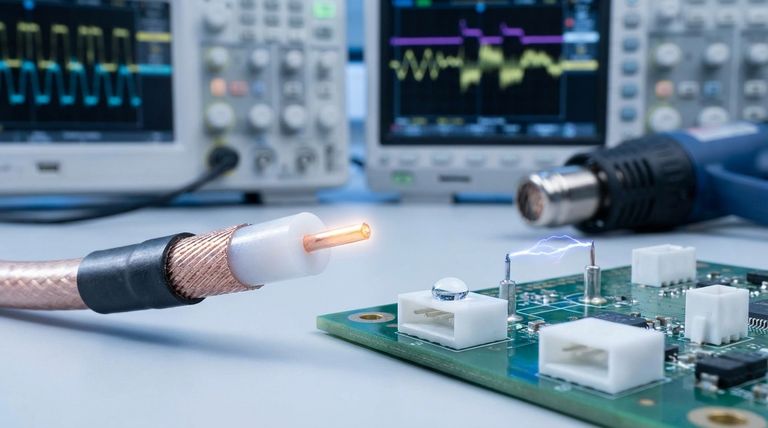

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How is PTFE produced? From TFE Gas to High-Performance Polymer

- What makes PTFE chemically resistant and why is this advantageous? Achieve Unmatched Reliability in Harsh Environments

- Why is PTFE used in medical equipment? Ensuring Safety and Performance in Critical Devices

- What are some consumer product applications of PTFE? Discover its Versatility Beyond Non-Stick Pans

- Why is virgin PTFE preferred for certain applications? Ensuring Purity for Critical Performance

- What is the temperature range for PTFE applications? Choose the Right Grade for Your High-Temp Needs

- What significant discovery about PTFE was made in the 1990s? Unlock Enhanced Performance with Radiation Cross-Linking

- What is Teflon/PTFE material and what are its key properties? Unlock Its High-Performance Capabilities