In short, a PTFE coating is applied to nitrile seals to dramatically lower surface friction and improve chemical resistance. This thin, bonded layer gives the flexible nitrile rubber the slick, non-stick, and inert properties of PTFE, solving common issues in dynamic and chemically aggressive environments.

The core takeaway is that a PTFE coating enhances a standard nitrile seal, combining the elasticity and sealing force of rubber with the low-friction and chemically-resistant surface of a high-performance polymer. It is a targeted upgrade for specific operational challenges.

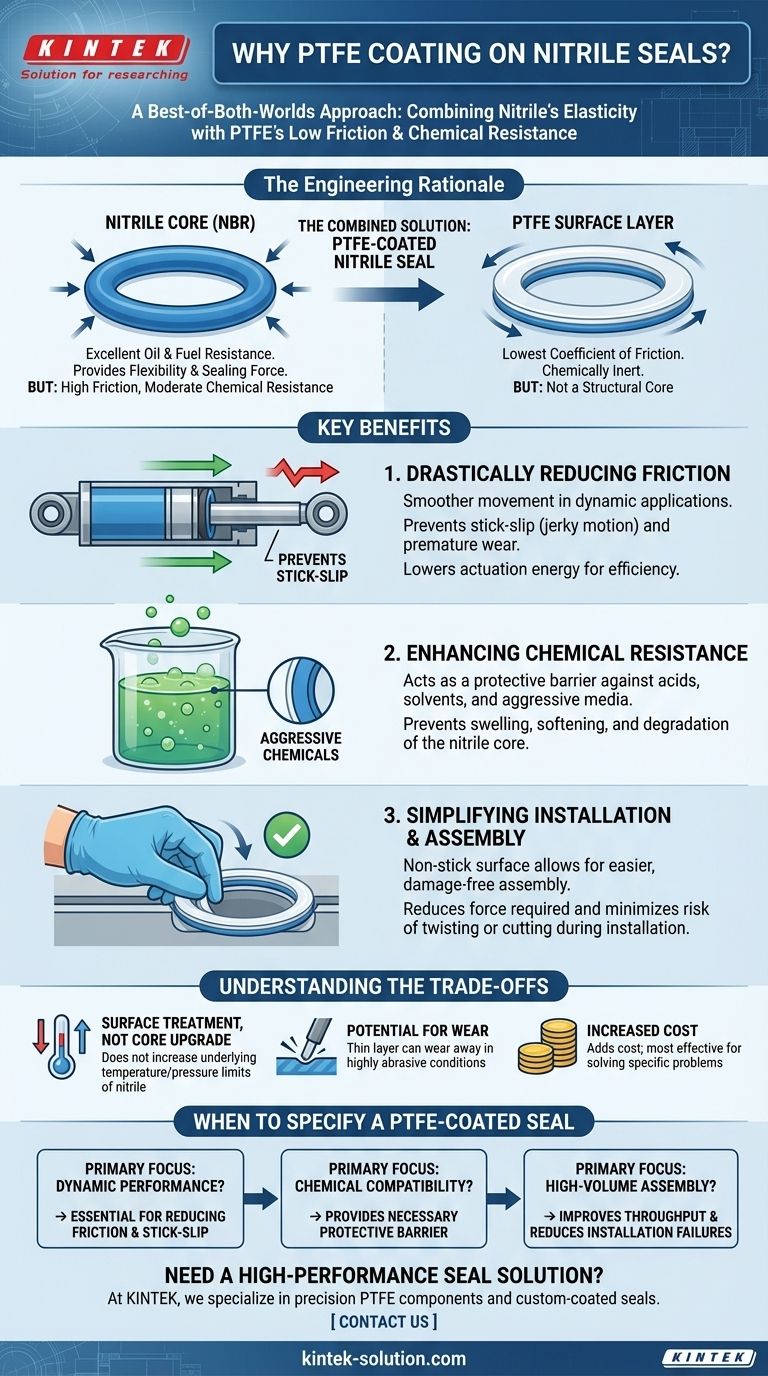

The Engineering Rationale: A Best-of-Both-Worlds Approach

To understand the value of the coating, we must first recognize the distinct properties of each material and the problem this combination solves.

The Role of the Nitrile Core

Nitrile rubber (NBR) is a widely used elastomer prized for its excellent resistance to oils, fuels, and hydraulic fluids.

Its primary function is to be flexible and elastic. This allows it to conform to sealing surfaces and maintain a consistent sealing force under pressure.

However, in certain applications, its relatively high coefficient of friction and moderate chemical resistance can be limiting factors.

PTFE as the Ideal Surface Layer

Polytetrafluoroethylene (PTFE) is a fluoropolymer with a unique set of properties that make it an ideal surface treatment.

It is famous for having one of the lowest coefficients of friction of any solid material, giving it a slick, non-stick quality.

Furthermore, PTFE is almost completely chemically inert, meaning it can withstand exposure to aggressive acids, solvents, and other chemicals that would degrade nitrile rubber.

Key Benefits of a PTFE-Coated Seal

Applying a thin, bonded layer of PTFE to the critical surfaces of a nitrile seal provides three distinct advantages that solve common engineering problems.

1. Drastically Reducing Friction

In dynamic applications, such as hydraulic or pneumatic cylinders, high friction can cause problems.

The PTFE coating creates a low-friction surface that allows the seal to move smoothly. This prevents a phenomenon known as stick-slip, where the seal alternately sticks and releases, causing jerky movement and premature wear.

Reduced friction also lowers the energy required to actuate the system, improving overall efficiency.

2. Enhancing Chemical Resistance

The PTFE layer acts as a protective barrier between the sealing media and the nitrile elastomer.

This shield prevents aggressive chemicals from being absorbed by the nitrile, which could otherwise cause it to swell, soften, or degrade over time.

This significantly expands the range of applications for a cost-effective nitrile seal, allowing its use in environments it could not otherwise tolerate.

3. Simplifying Installation and Assembly

The non-stick nature of PTFE makes seals easier to install, particularly in automated assembly lines.

The slick surface reduces the force required to slide the seal into a groove or bore, minimizing the risk of it being twisted, cut, or damaged during installation.

Understanding the Trade-offs

While highly effective, this composite design is not a universal solution. It's essential to recognize its limitations to make an informed decision.

The Coating is a Surface Treatment, Not a Core Upgrade

The underlying temperature and pressure limitations of the nitrile rubber remain. The PTFE coating does not increase the seal's fundamental operating range.

If your application exceeds the temperature or pressure rating of nitrile, you must select a seal made from a different base material, such as a solid PTFE or high-performance elastomer.

Potential for Wear or Delamination

The PTFE coating is a very thin layer. In highly abrasive conditions or after an extremely long service life, this layer can wear away.

While the bonding process is robust, there is a theoretical risk of delamination under extreme stress, which would negate the benefits of the coating.

Increased Cost

Adding a precision coating process inherently increases the cost of the component compared to a standard, uncoated nitrile seal.

This solution is most cost-effective when its specific benefits directly solve a known performance or assembly problem.

When to Specify a PTFE-Coated Nitrile Seal

Use this framework to determine if this specialized seal is the right choice for your application.

- If your primary focus is dynamic performance: A PTFE coating is essential for preventing stick-slip and reducing actuation energy in moving applications.

- If your primary focus is chemical compatibility: The coating provides a necessary barrier to protect the nitrile from media that would otherwise cause seal failure.

- If your primary focus is high-volume or automated assembly: The non-stick surface reduces installation failures and improves manufacturing throughput.

Ultimately, choosing a PTFE-coated seal is an engineering decision to enhance a proven material for a more demanding role.

Summary Table:

| Benefit | Solves This Problem |

|---|---|

| Drastic Friction Reduction | Prevents stick-slip, lowers actuation force, and reduces wear in dynamic applications. |

| Enhanced Chemical Resistance | Protects the nitrile core from aggressive media like acids and solvents. |

| Simplified Installation | The non-stick surface allows for easier, damage-free assembly. |

Need a high-performance seal solution for your application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom-coated seals for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication ensures you get a seal that perfectly combines the elasticity of nitrile with the superior surface properties of PTFE.

Contact us today to discuss your requirements for prototypes or high-volume orders and enhance your system's reliability and efficiency.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key steps for properly installing PTFE seals? Ensure a Leak-Free, Long-Lasting Seal

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance