In short, Polytetrafluoroethylene (PTFE) is highly suitable for medical laboratories due to its exceptional chemical inertness, biocompatibility, and high resistance to radiation. This unique combination of properties makes it a reliable material for handling corrosive substances, manufacturing medical instruments, and shielding sensitive radiological equipment.

The core reason for PTFE's prevalence is its extreme stability. In an environment where the slightest chemical reaction, contamination, or material degradation can invalidate research or compromise patient safety, PTFE provides a uniquely non-reactive and durable solution.

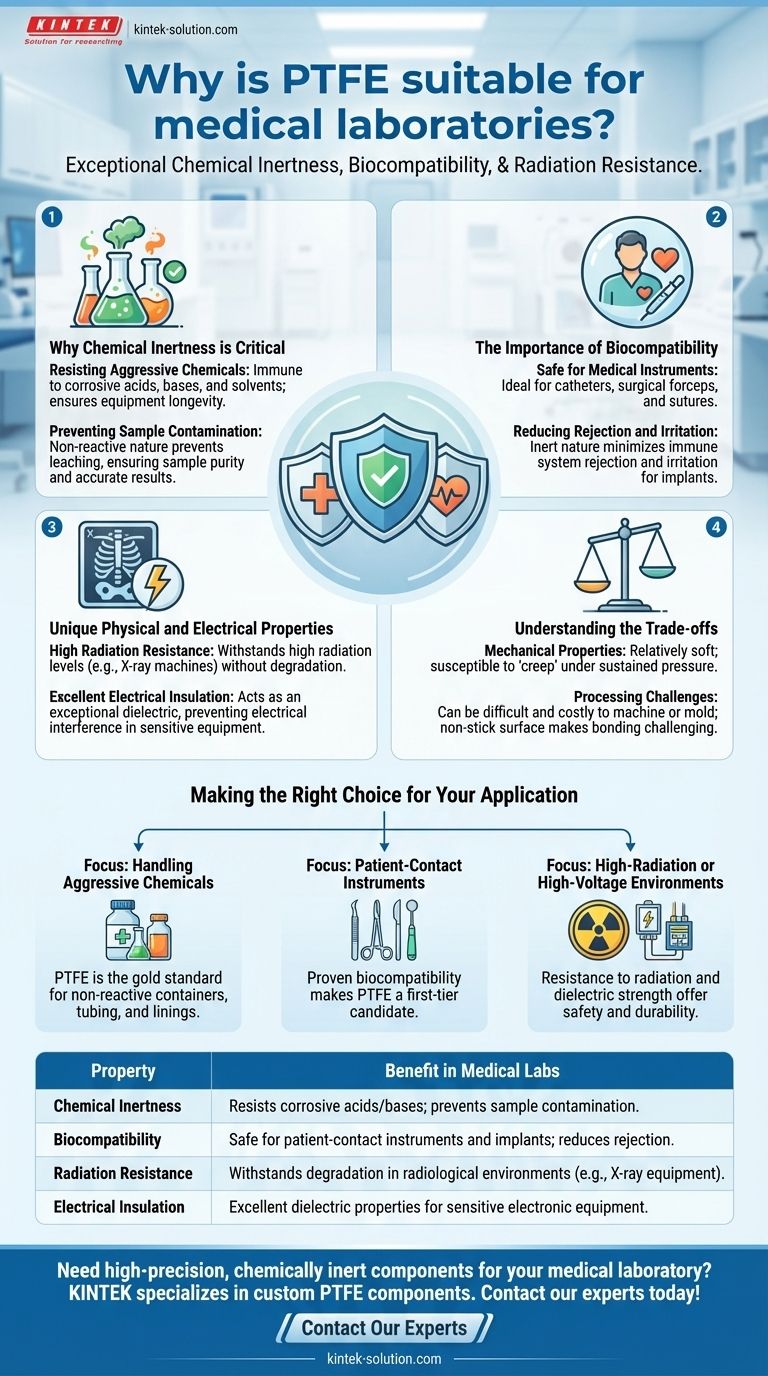

Why Chemical Inertness is Critical

In a laboratory, material integrity is paramount. The equipment cannot react with the substances it holds, as this would compromise both the experiment and the equipment itself.

Resisting Aggressive Chemicals

Medical and chemical labs frequently use highly corrosive acids, bases, and solvents. PTFE is virtually immune to all of them, ensuring that pipes, containers, and linings do not corrode or degrade over time.

Preventing Sample Contamination

Because PTFE is so non-reactive, it does not leach chemicals into the samples it contains. This is critical for ensuring the purity of reagents and the accuracy of experimental results, where even trace amounts of contamination can lead to false outcomes.

The Importance of Biocompatibility

When materials are used in applications involving direct or indirect contact with biological tissue, their interaction with the body becomes a primary concern.

Safe for Medical Instruments

PTFE is biocompatible, meaning it does not cause an adverse reaction when it comes into contact with the human body. This makes it an ideal material for manufacturing instruments like catheters, surgical forceps, and even sutures.

Reducing Rejection and Irritation

The inert nature of PTFE minimizes the risk of the body's immune system rejecting an instrument or implant. This property is essential for both temporary devices and long-term medical implants.

Unique Physical and Electrical Properties

Beyond its chemical and biological stability, PTFE possesses other physical characteristics that make it valuable in a high-tech laboratory setting.

High Radiation Resistance

Medical labs often utilize radiological equipment, such as X-ray machines. PTFE’s ability to withstand high levels of radiation without degrading makes it a suitable material for shielding components and ensuring equipment longevity.

Excellent Electrical Insulation

PTFE is an exceptional electrical insulator, or dielectric. In a lab filled with sensitive electronic equipment, using PTFE for components helps prevent electrical interference and ensures the safe operation of devices.

Understanding the Trade-offs

No material is perfect for every application. While PTFE's advantages are significant, it's important to be aware of its limitations.

Mechanical Properties

Compared to metals or other engineering plastics, PTFE is a relatively soft material. It can be susceptible to "creep" (slow deformation) under sustained pressure and has lower tensile strength.

Processing Challenges

PTFE can be more difficult and costly to machine or mold than more common polymers. Its non-stick surface, a benefit in many applications, also makes it difficult to bond to other materials using adhesives.

Making the Right Choice for Your Application

Your specific goal will determine whether PTFE is the optimal choice.

- If your primary focus is handling aggressive chemicals: PTFE is the gold standard for non-reactive containers, tubing, and linings.

- If your primary focus is developing patient-contact instruments: The proven biocompatibility of PTFE makes it a first-tier candidate for your design.

- If your primary focus is equipment for high-radiation or high-voltage environments: PTFE’s resistance to radiation and its dielectric strength offer critical safety and durability.

Ultimately, PTFE is chosen in medical labs because it provides an unparalleled level of safety and reliability where it matters most.

Summary Table:

| Property | Benefit in Medical Labs |

|---|---|

| Chemical Inertness | Resists corrosive acids/bases; prevents sample contamination. |

| Biocompatibility | Safe for patient-contact instruments and implants; reduces rejection. |

| Radiation Resistance | Withstands degradation in radiological environments (e.g., X-ray equipment). |

| Electrical Insulation | Excellent dielectric properties for sensitive electronic equipment. |

Need high-precision, chemically inert components for your medical laboratory?

KINTEK specializes in manufacturing custom PTFE components—including seals, liners, and labware—for the medical, semiconductor, and laboratory industries. We ensure your equipment meets the highest standards of safety, purity, and performance, from prototype to high-volume production.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are PTFE silicone septas and their role in the pharmaceutical industry? Ensure Sample Integrity and Accurate Analysis

- How are PTFE syringe filters modified for hydrophilic applications? Achieve Easy Filtration of Aqueous Solutions

- What types of equipment are PTFE ferromagnetic support discs compatible with? Boost Your Lab's Efficiency

- How do Teflon membranes enhance chemical resistance in laboratory equipment? Maximize Purity and Durability

- What are the benefits of reusing HPLC autosampler vials with PTFE/silicone septa? Save Costs & Boost Lab Sustainability

- Why are PTFE-coated septums preferred in chromatography? Ensure Sample Integrity and Accurate Results

- How should PTFE shovels be cleaned and stored? Protect Your Investment with Proper Care

- Why are PTFE and silicone rubber chosen as materials for HPLC septa? Ensure Sample Integrity and Reliable Sealing