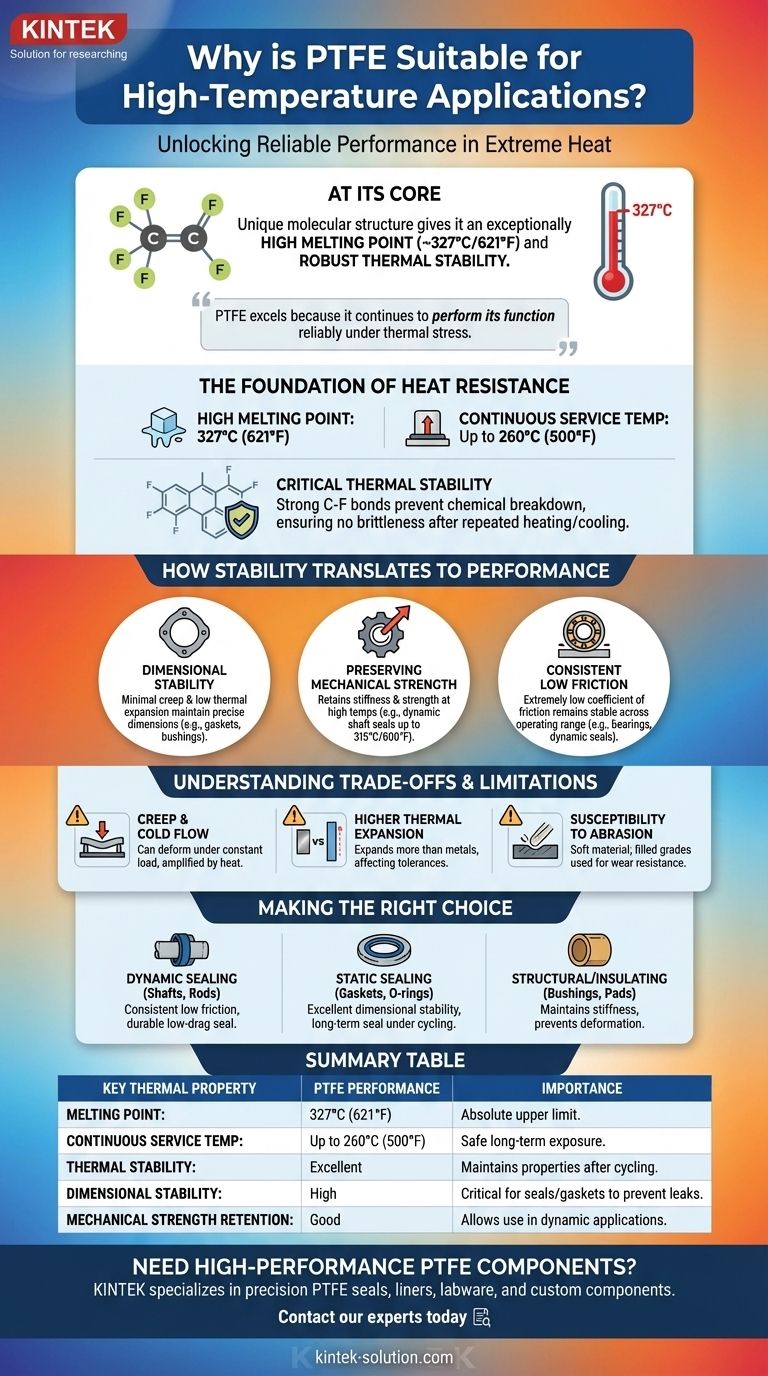

At its core, Polytetrafluoroethylene (PTFE) is suitable for high-temperature applications because of its unique molecular structure. This structure gives it an exceptionally high melting point of around 327°C (621°F) and robust thermal stability, which allows it to function reliably without chemical degradation or loss of critical properties when repeatedly exposed to extreme heat.

While many materials can simply survive high temperatures, PTFE excels because it continues to perform its function reliably. Its value comes not just from its heat resistance, but from its ability to maintain mechanical strength, dimensional stability, and low friction under thermal stress.

The Foundation of PTFE's Heat Resistance

To understand why PTFE is a go-to choice for demanding thermal environments, we must look beyond its melting point and examine the stability of its properties under load.

The High Melting Point

PTFE’s melting temperature of approximately 327°C (621°F) is significantly higher than that of most other plastics. This is the temperature at which the material transitions from a solid to a viscous liquid, representing its absolute upper thermal limit.

Continuous Service Temperature

More important for practical engineering is the continuous service temperature, which is the maximum temperature the material can withstand for extended periods without significant loss of properties. For PTFE, this is generally rated up to 260°C (500°F).

The Critical Role of Thermal Stability

Thermal stability refers to a material's ability to resist chemical decomposition at high temperatures. PTFE's carbon-fluorine bonds are incredibly strong, preventing the polymer chains from breaking down. This ensures it doesn't become brittle or degrade after repeated heating and cooling cycles.

How Thermal Stability Translates to Performance

A high melting point is useless if a component deforms or fails under operational stress. PTFE's key advantage is its ability to retain its defining characteristics when hot.

Maintaining Dimensional Stability

In applications like gaskets and bushings, maintaining shape is critical. PTFE exhibits minimal creep (deformation under sustained load) and low thermal expansion compared to other polymers. This allows PTFE seals and bushes to maintain their precise dimensions and prevent leaks or failures when temperatures rise.

Preserving Mechanical Strength

While all plastics soften with heat, PTFE retains a high degree of its stiffness and structural strength at its upper service temperature. This allows it to be used for components like dynamic shaft seals that must endure mechanical forces in abusive temperature conditions up to 315°C (600°F).

Consistent Low Friction

One of PTFE's most famous properties is its extremely low coefficient of friction. Crucially, this property remains stable across its entire operating temperature range. This is vital for high-temperature bearings or dynamic seals where consistent, low-drag movement is required.

Understanding the Trade-offs and Limitations

No material is perfect. A true technical understanding requires acknowledging PTFE's limitations in high-temperature design.

Creep and Cold Flow

While good for a polymer, PTFE can still exhibit "creep" or "cold flow," slowly deforming under a constant load. This effect is amplified at higher temperatures and must be accounted for in the design of high-load static seals or structural parts.

Higher Thermal Expansion Than Metals

When designing a system that combines PTFE and metal components, it is critical to account for their different rates of thermal expansion. PTFE expands and contracts more than steel or aluminum, which can affect tolerances and sealing pressures across a wide temperature range.

Susceptibility to Abrasion

Pure PTFE is a relatively soft material and can be susceptible to wear and abrasion, especially in dynamic applications with rough mating surfaces. For such cases, filled grades of PTFE (e.g., glass-filled or carbon-filled) are often used to improve wear resistance.

Making the Right Choice for Your Application

Selecting PTFE is about matching its unique thermal stability to a specific engineering need.

- If your primary focus is dynamic sealing (shafts, rods): PTFE's combination of consistent low friction and retained strength at high temperatures ensures a durable, low-drag seal.

- If your primary focus is static sealing (gaskets, O-rings): Its excellent dimensional stability and resistance to creep provide a reliable, long-term seal that won't fail under thermal cycling.

- If your primary focus is structural or insulating components (bushings, pads): PTFE's ability to maintain its stiffness and form under thermal load prevents deformation and failure where lesser plastics would warp.

Ultimately, choosing PTFE is a decision to prioritize consistent, reliable performance when your application cannot afford to fail under heat.

Summary Table:

| Key Thermal Property | PTFE Performance | Importance for Applications |

|---|---|---|

| Melting Point | 327°C (621°F) | Defines the absolute upper thermal limit. |

| Continuous Service Temp | Up to 260°C (500°F) | Safe for long-term exposure without degradation. |

| Thermal Stability | Excellent | Maintains properties after repeated heating/cooling cycles. |

| Dimensional Stability | High | Critical for seals and gaskets to prevent leaks under heat. |

| Mechanical Strength Retention | Good | Allows use in dynamic applications like shaft seals. |

Need high-performance PTFE components that won't fail under heat?

KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. We ensure your parts deliver reliable thermal stability, dimensional integrity, and long-lasting performance, from prototypes to high-volume orders.

Contact our experts today to discuss your high-temperature application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the key specifications of PTFE material? Unlock Its Extreme Performance & Limits

- What are the processing challenges with PTFE material? Overcoming Creep, Cold Flow, and Low Strength

- How do the low friction properties of PTFE benefit pharmaceutical manufacturing setups? Boost Efficiency & Cut Costs

- What are some lesser-known facts about Teflon? Uncover Its Hidden Role in Tech and Industry

- How is PTFE used in the electrical industry? Unlock Superior Insulation for High-Frequency Applications

- What are the culinary applications of Teflon? Leverage Non-Stick Performance for Cooking & Processing

- How does Teflon perform in harsh chemical environments? Unmatched Chemical Resistance for Demanding Applications

- What are the key features of PTFE? Unmatched Chemical & Thermal Stability for Demanding Applications