At its core, Polytetrafluoroethylene (PTFE) is the material of choice for high-friction applications because it has the lowest coefficient of friction of any known solid. This unique molecular property allows it to function as a self-lubricating surface, drastically reducing resistance and wear even in dry, non-lubricated conditions where other materials would fail.

The preference for PTFE isn't just about its inherent "slipperiness." It's about how this single property creates a cascade of system-wide benefits: reduced mechanical wear, lower energy consumption, and greater operational reliability, ultimately leading to more efficient and durable components.

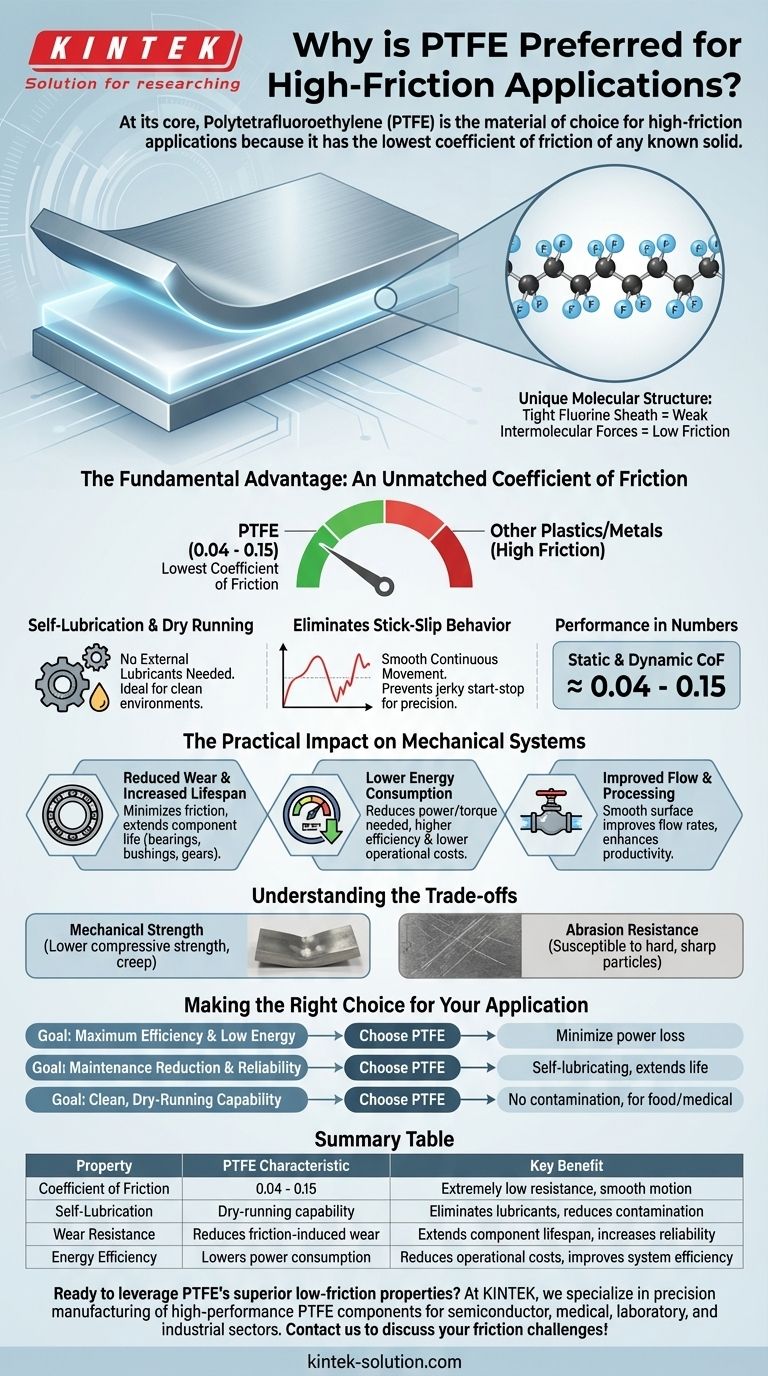

The Fundamental Advantage: An Unmatched Coefficient of Friction

PTFE's performance is rooted in its unique molecular structure. The fluorine atoms create a tight, uniform sheath around the carbon backbone, resulting in very weak intermolecular forces. This structure is what makes the surface so exceptionally non-reactive and low-friction.

Performance in Numbers

The static and dynamic coefficients of friction for PTFE are nearly identical, typically ranging from 0.04 to 0.15. This is significantly lower than most other plastics and metals, making the transition from a standstill to motion incredibly smooth.

Self-Lubrication and Dry Running

Unlike materials such as rubber elastomers, PTFE does not require external lubricants like oil or grease to perform. This "dry running" capability is critical in applications where contamination is a concern or where maintenance for re-lubrication is impractical.

Eliminating Stick-Slip Behavior

Because its static friction is so low and close to its dynamic friction, PTFE prevents the jerky start-stop motion known as stick-slip. This ensures smooth, continuous movement, which is vital for precision equipment and control systems.

The Practical Impact on Mechanical Systems

The theoretical advantage of low friction translates directly into tangible engineering benefits that improve the performance and lifespan of machinery.

Reduced Wear and Increased Component Lifespan

By minimizing frictional resistance, PTFE dramatically reduces wear on both itself and the components it contacts. This is why it's a primary choice for bearings, bushings, gears, and slides, as it extends the operational life of the entire assembly.

Lower Energy Consumption

Friction is a primary source of energy loss in mechanical systems. By using PTFE, engineers can significantly reduce the power and torque required to operate equipment, leading to higher overall efficiency and lower operational costs.

Improved Flow and Processing

In applications like valves, PTFE's smooth, low-friction surface improves flow rates. Less resistance allows more material to be processed per cycle, enhancing productivity in chemical and industrial manufacturing.

Understanding the Trade-offs

While its low-friction properties are unparalleled, PTFE is not the solution for every engineering challenge. Objectivity requires acknowledging its limitations.

Mechanical Strength

PTFE is a relatively soft material with lower compressive strength compared to many engineering plastics and metals. Under high loads, it can be susceptible to creep, or cold flow, where the material slowly deforms over time.

Abrasion Resistance

While PTFE resists wear from smooth, sliding contact, it can be abraded by hard, sharp particles. In environments with abrasive contaminants, a harder material may be required.

Thermal Properties

PTFE has a well-defined and useful service temperature range, but it is not suitable for extremely high-temperature applications where metals or ceramics would be necessary.

Making the Right Choice for Your Application

Selecting PTFE should be a deliberate decision based on the primary goal of your design.

- If your primary focus is maximum efficiency and low energy use: PTFE is the ideal choice to minimize power loss caused by friction in mechanical systems.

- If your primary focus is maintenance reduction and reliability: Its self-lubricating nature and inherent wear resistance extend component life and reduce the need for service.

- If your primary focus is clean, dry-running capability: PTFE excels in environments where external lubricants are undesirable, such as in food processing, medical devices, or electronics.

By understanding these core principles, you can leverage PTFE's unique properties to engineer more robust, efficient, and reliable systems.

Summary Table:

| Property | PTFE Characteristic | Key Benefit |

|---|---|---|

| Coefficient of Friction | 0.04 - 0.15 | Extremely low resistance, smooth motion |

| Self-Lubrication | Dry-running capability | Eliminates need for external lubricants, reduces contamination |

| Wear Resistance | Reduces friction-induced wear | Extends component lifespan, increases reliability |

| Energy Efficiency | Lowers power consumption | Reduces operational costs, improves system efficiency |

Ready to leverage PTFE's superior low-friction properties in your components?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components—including seals, liners, bearings, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume order, our expertise ensures your parts deliver maximum efficiency, reliability, and longevity.

Contact us today to discuss how our custom PTFE solutions can solve your friction challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What precautions should be taken when specifying PTFE Lip Seals? Ensure Long-Term Reliability for Your Application

- What challenges are associated with CNC milling of PTFE? Overcome Softness and Thermal Expansion

- What types of equipment commonly use ePTFE gaskets? Solve Your Toughest Sealing Challenges

- What are the installation requirements for PTFE Lined Butterfly Valves? Ensure Long-Term Reliability & Prevent Failure

- Why is the non-stick surface of PTFE bushings beneficial? For Contamination-Free, Low-Maintenance Performance

- What factors should be considered when choosing a PTFE-lined valve? Ensure Optimal Performance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the common types of fillers used in PTFE compounds? Enhance Performance for Demanding Applications