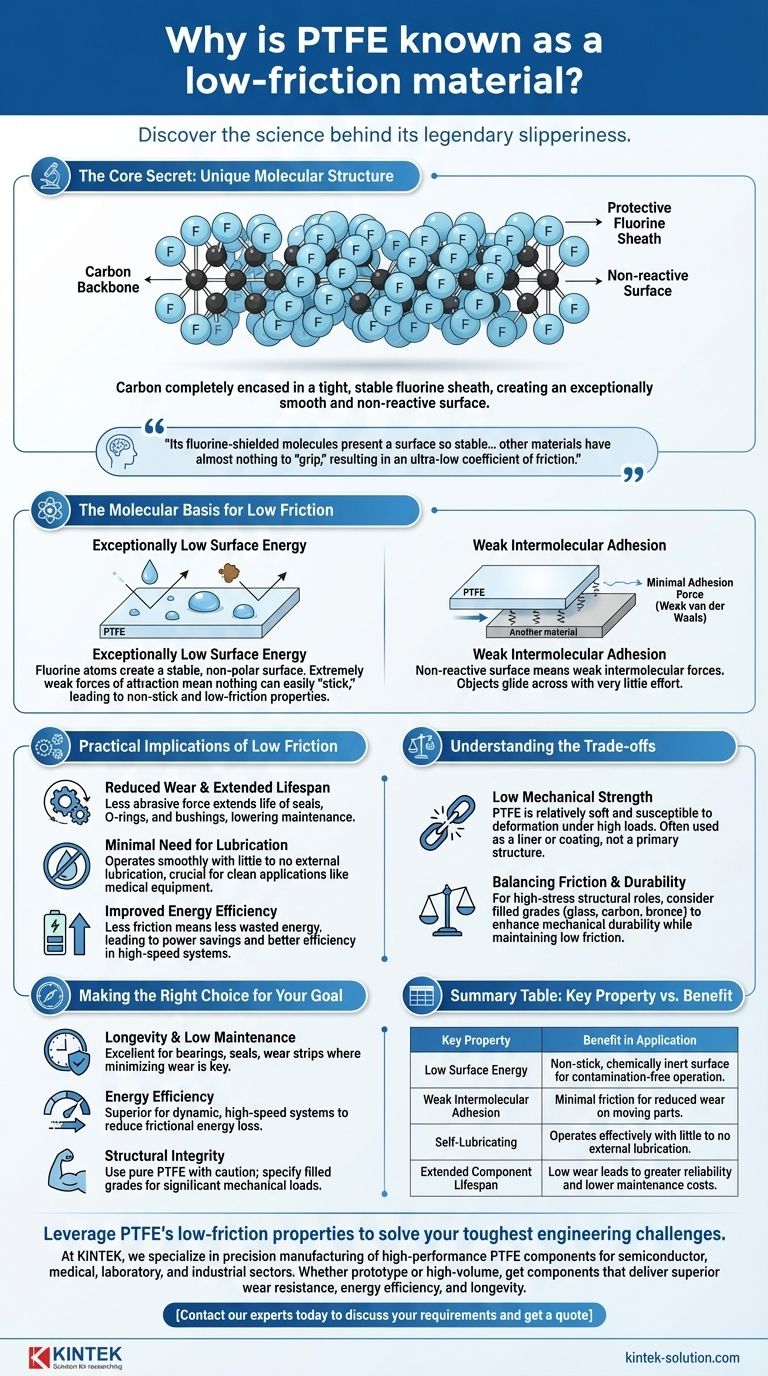

At its core, Polytetrafluoroethylene (PTFE) is a low-friction material because of its unique molecular structure. The polymer's carbon backbone is completely encased in a tight, stable sheath of fluorine atoms, creating an exceptionally smooth and non-reactive surface that resists bonding with other materials, allowing them to slide past with minimal resistance.

The true reason for PTFE's legendary slipperiness lies not in its hardness, but in its chemical indifference. Its fluorine-shielded molecules present a surface so stable and with such low energy that other materials have almost nothing to "grip," resulting in an ultra-low coefficient of friction.

The Molecular Basis for Low Friction

To understand why PTFE is so effective, we must look at its atomic composition. The material's properties are a direct result of the powerful bond between carbon and fluorine atoms.

The Protective Fluorine Sheath

PTFE consists of a long chain of carbon atoms, where each carbon is bonded to two fluorine atoms. These fluorine atoms are relatively large and highly electronegative, forming a dense, helical sheath around the carbon backbone.

This sheath effectively shields the carbon chain from interacting with other substances, creating a chemically inert and uniform outer surface.

Exceptionally Low Surface Energy

The stable, non-polar surface created by the fluorine atoms gives PTFE one of the lowest surface energies of any solid. This means there are very weak forces of attraction between PTFE molecules and the molecules of other materials.

Because other substances are not attracted to its surface, they cannot easily "stick" to it. This property is responsible for both its non-stick and its low-friction characteristics.

Weak Intermolecular Adhesion

Friction is fundamentally a measure of the force required to slide one surface over another. This force is heavily influenced by adhesion between the two surfaces.

Since PTFE's surface is so non-reactive, the intermolecular forces (van der Waals forces) between it and another material are exceptionally weak. This lack of adhesion allows objects to glide across its surface with very little effort.

Practical Implications of a Low-Friction Surface

The theoretical properties of PTFE's molecular structure translate directly into significant real-world advantages in mechanical and industrial applications.

Reduced Wear and Extended Lifespan

The primary benefit of low friction is a dramatic reduction in wear and tear between moving parts. Components like seals, O-rings, and bushings made from PTFE last significantly longer because they generate less abrasive force.

This directly extends the service life of both the PTFE component and the surfaces it contacts, leading to lower maintenance costs and greater reliability.

Minimal Need for Lubrication

In many dynamic systems, PTFE can operate smoothly with little to no external lubrication. This makes it invaluable for applications where lubricants could be a contaminant, such as in medical equipment, or in places that are difficult to service.

Improved Energy Efficiency

Less friction means less energy is wasted overcoming resistance. In high-speed applications like impellers or dynamic seals in the automotive and aerospace industries, using PTFE can result in significant power savings and improved overall efficiency.

Understanding the Trade-offs

While its low-friction nature is a major advantage, it is not a perfect material for every situation. Understanding its limitations is key to using it effectively.

Low Mechanical Strength

PTFE is a relatively soft plastic. Its low-friction properties do not translate to high strength or resistance to physical damage.

This softness means pure PTFE components are susceptible to deformation under high loads and require careful handling to prevent damage. This is why it is often used as a liner or coating rather than a primary structural component.

Balancing Friction and Durability

The choice to use PTFE often involves a trade-off between its excellent friction characteristics and its modest mechanical properties. While it is inexpensive and easy to machine, its lack of rigidity means it may not be suitable for high-stress structural roles.

For applications requiring both low friction and higher strength, filled grades of PTFE (mixed with materials like glass, carbon, or bronze) are often used to enhance its mechanical durability.

Making the Right Choice for Your Goal

Selecting PTFE is about leveraging its unique strengths for the correct application. Your primary objective will determine if it's the right fit.

- If your primary focus is longevity and low maintenance: PTFE is an excellent choice for components like bearings, seals, and wear strips where minimizing wear without constant lubrication is the main goal.

- If your primary focus is energy efficiency: In dynamic, high-speed systems, PTFE's ability to reduce frictional energy loss makes it a superior material for improving performance and reducing operational costs.

- If your primary focus is structural integrity: Pure PTFE should be used with caution; consider it for liners or coatings, or specify a filled grade if the part must also bear a significant mechanical load.

By understanding that PTFE's value comes from its unique molecular structure, you can strategically apply it to solve critical engineering challenges related to friction, wear, and efficiency.

Summary Table:

| Key Property | Benefit in Application |

|---|---|

| Low Surface Energy | Non-stick, chemically inert surface for contamination-free operation. |

| Weak Intermolecular Adhesion | Minimal friction for reduced wear on seals, bearings, and moving parts. |

| Self-Lubricating | Operates effectively with little to no external lubrication. |

| Extended Component Lifespan | Low wear and tear leads to greater reliability and lower maintenance costs. |

Leverage PTFE's low-friction properties to solve your toughest engineering challenges.

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or high-volume production, our expertise ensures you get components that deliver superior wear resistance, energy efficiency, and longevity.

Contact our experts today to discuss your specific requirements and get a quote for your custom PTFE solution.

Visual Guide

Related Products

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- What are the main advantages of PTFE as a material for laboratory bottles? Superior Chemical & Thermal Resistance

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications

- What is the molecular structure of PTFE? The Key to Its Unmatched Chemical & Thermal Resistance

- What are the key applications of the PTFE bottle? Ensure Chemical Safety and Sample Purity