At its core, Polytetrafluoroethylene (PTFE) is considered safe for food and pharmaceutical applications because of its fundamental chemical nature. It is an inert, non-toxic polymer that is FDA-approved for direct contact with consumables. This safety is reinforced by its high-temperature resistance and non-stick surface, which are critical for maintaining the hygienic conditions required in these sensitive industries.

The safety of PTFE isn't just about its non-toxic composition; it's about a combination of properties—chemical inertness, temperature stability, and a non-stick surface—that work together to create a stable, clean, and non-contaminating barrier between processing equipment and the final product.

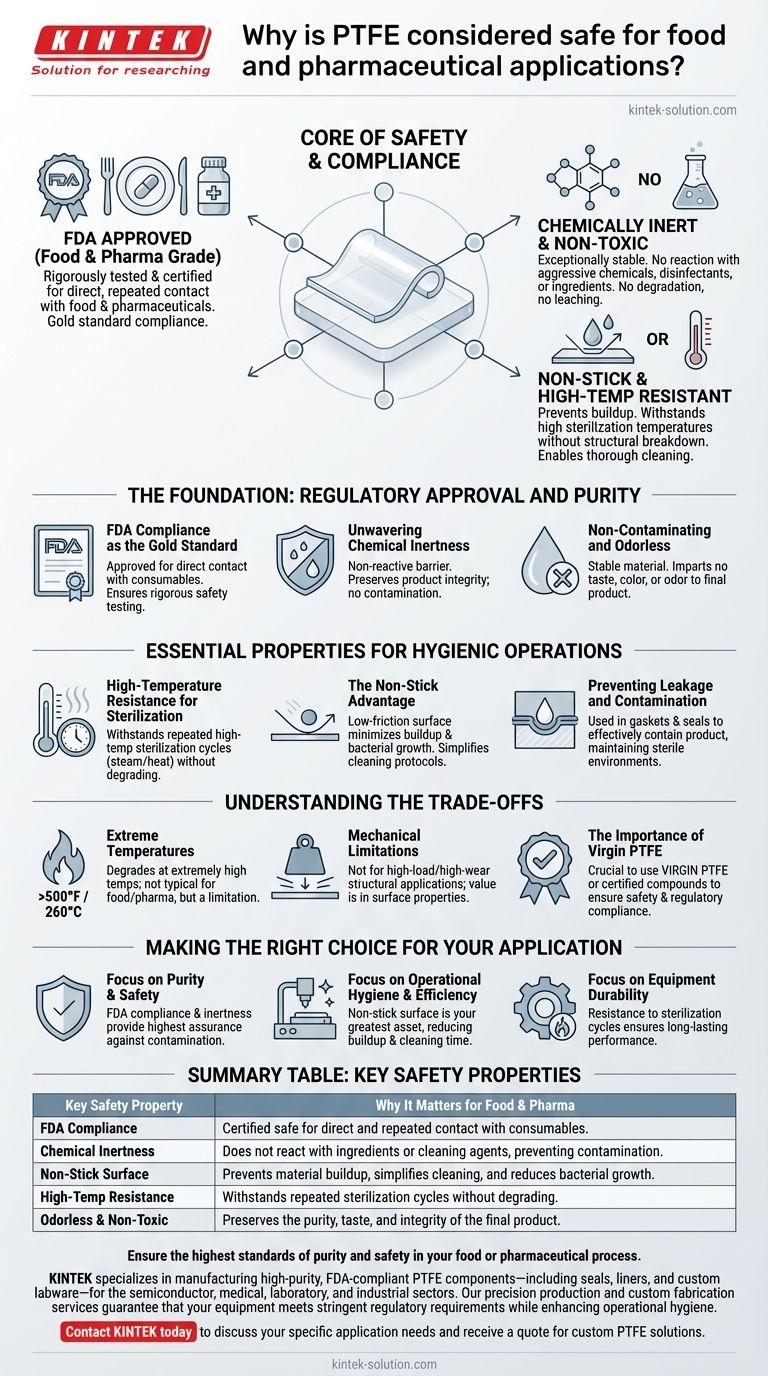

The Foundation: Regulatory Approval and Purity

The suitability of any material in food and pharma begins with its inherent safety and official compliance. PTFE excels in this area, providing a reliable foundation for its use.

FDA Compliance as the Gold Standard

PTFE is recognized and approved by the U.S. Food and Drug Administration (FDA) as a food-grade material. This designation means it has been rigorously tested and is certified safe for direct and repeated contact with food, beverages, and pharmaceutical products.

Unwavering Chemical Inertness

This material is exceptionally non-reactive. It does not react with aggressive cleaning agents, potent disinfectants, or the active ingredients in pharmaceutical compounds. This inertness is critical because it prevents the material from degrading and leaching harmful substances into the product.

Non-Contaminating and Odorless

Because PTFE is chemically stable, it does not impart any taste, color, or odor to the substances it touches. This ensures the purity and integrity of the final consumable product, which is a non-negotiable requirement in these industries.

Essential Properties for Hygienic Operations

Beyond its inherent purity, PTFE's physical properties are uniquely suited to the practical challenges of maintaining a sterile and efficient production environment.

High-Temperature Resistance for Sterilization

Food and pharmaceutical equipment must be frequently sterilized, often using high-temperature steam or other methods. PTFE can withstand these high temperatures without breaking down or losing its structural integrity, allowing for effective and repeated sterilization cycles that kill harmful bacteria.

The Non-Stick Advantage

PTFE’s famous low-friction, non-stick surface is a major asset for hygiene. It prevents food ingredients and pharmaceutical powders from building up on equipment surfaces like hoppers and mixers. This lack of buildup minimizes the risk of bacterial growth and makes equipment significantly easier to clean thoroughly.

Preventing Leakage and Contamination

In machinery like pumps, mixers, and reactors, maintaining a perfect seal is crucial to prevent leaks and cross-contamination. PTFE is widely used for gaskets and seals because it effectively contains the product, ensuring that sterile environments remain sterile and that product integrity is maintained throughout the process.

Understanding the Trade-offs

While PTFE is exceptionally well-suited for these applications, no material is perfect. Acknowledging its limitations provides a complete picture for making informed decisions.

Considerations at Extreme Temperatures

While its heat resistance is excellent for sterilization, PTFE can begin to degrade at extremely high temperatures (well above 500°F or 260°C). This is not typically a concern in food or pharma processing but is a fundamental limitation of the material.

Mechanical Limitations

PTFE is a relatively soft polymer. It is not suitable for high-load or high-wear structural applications where mechanical strength and abrasion resistance are the primary requirements. Its value lies in its surface properties and chemical stability, not its raw strength.

The Importance of Virgin PTFE

For food and pharmaceutical use, it is critical to use virgin PTFE or compounds specifically formulated and certified for these applications. Using a grade of PTFE with non-compliant fillers or additives would completely negate its safety profile and violate regulatory standards.

Making the Right Choice for Your Application

Selecting PTFE is about aligning its specific strengths with your most critical operational goals.

- If your primary focus is product purity and safety: PTFE's FDA compliance and chemical inertness provide the highest assurance that the material will not contaminate or alter your product.

- If your primary focus is operational hygiene and efficiency: The non-stick surface is your greatest asset, as it simplifies cleaning protocols and prevents the material buildup that can harbor bacteria.

- If your primary focus is equipment durability in sterile environments: PTFE's resistance to high temperatures and aggressive cleaning chemicals ensures it will not degrade from repeated, necessary sterilization cycles.

Ultimately, PTFE's unique combination of properties makes it one of the most trusted materials for ensuring safety and integrity where it matters most.

Summary Table:

| Key Safety Property | Why It Matters for Food & Pharma |

|---|---|

| FDA Compliance | Certified safe for direct and repeated contact with consumables. |

| Chemical Inertness | Does not react with ingredients or cleaning agents, preventing contamination. |

| Non-Stick Surface | Prevents material buildup, simplifies cleaning, and reduces bacterial growth. |

| High-Temp Resistance | Withstands repeated sterilization cycles without degrading. |

| Odorless & Non-Toxic | Preserves the purity, taste, and integrity of the final product. |

Ensure the highest standards of purity and safety in your food or pharmaceutical process.

KINTEK specializes in manufacturing high-purity, FDA-compliant PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services, from prototypes to high-volume orders, guarantee that your equipment meets stringent regulatory requirements while enhancing operational hygiene.

Contact KINTEK today to discuss your specific application needs and receive a quote for custom PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the medical applications of PTFE? Critical Uses in Implants and Instruments

- What is the role of polypropylene netting in PTFE laminated membrane filters? Ensuring Durability and Performance

- How does PTFE protect against corrosion? A Barrier Against Chemicals, Water, and Galvanic Corrosion

- What are the properties of bronze-filled PTFE? A High-Performance Composite for Demanding Applications

- Why is PTFE considered ideal for use in the food and beverage industry? Ensure Safety & Efficiency

- What are the common uses of Teflon? A Guide to PTFE's Versatile Applications

- How do fillers affect PTFE properties? Transform PTFE into a High-Performance Material

- What are the limitations of PTFE in its applications? Understanding Its Mechanical Weaknesses