At its core, Polytetrafluoroethylene (PTFE) is considered safe for food and beverage applications because it is exceptionally non-reactive. It is chemically inert and non-toxic, which means it does not break down, leach chemicals, or interact with food products it touches. This fundamental stability is why regulatory bodies like the FDA have approved it for direct food contact.

The safety of PTFE in the food industry is not just about a lack of toxicity; it is about its profound chemical stability. This stability ensures that the material acts as a neutral barrier, preserving the purity, taste, and safety of the food it contacts.

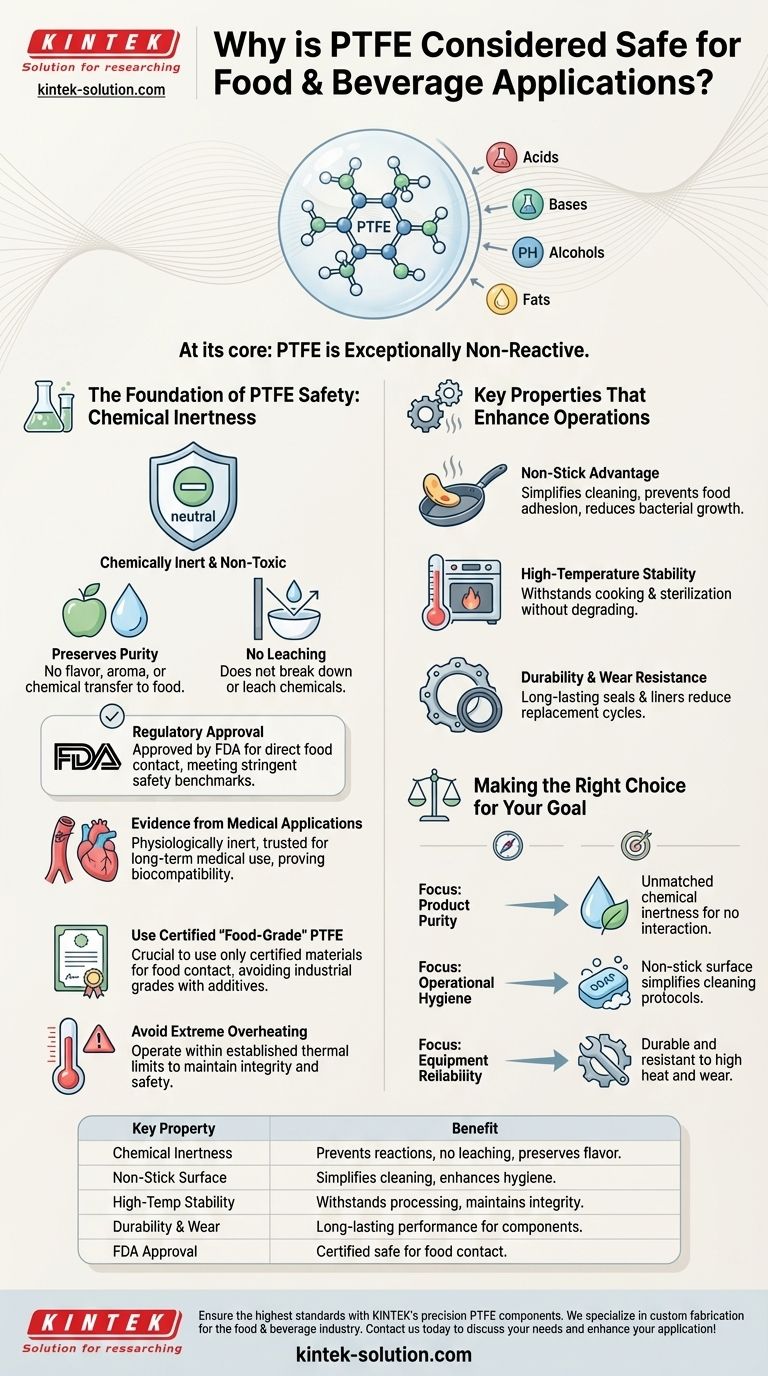

The Foundation of PTFE Safety: Chemical Inertness

The primary reason PTFE is a trusted material in food processing is its chemical makeup. Its properties create an incredibly stable and safe material for handling consumables.

What "Inert" Means for Food Purity

Being chemically inert means PTFE does not react with acids, bases, alcohols, or fats commonly found in food and beverages. This prevents any chemical transfer from the material to the food.

This property ensures that the food's flavor, aroma, and chemical composition remain completely unchanged, guaranteeing product purity.

Regulatory Approval as a Benchmark

PTFE's safety is validated by stringent regulatory bodies. Its approval by the U.S. Food and Drug Administration (FDA) for food contact applications serves as a critical benchmark for safety and compliance.

This certification confirms that the material has undergone rigorous testing and is suitable for use in commercial food processing and packaging.

Evidence from Medical Applications

The inertness of PTFE is so profound that it is used in highly sensitive medical applications. It is physiologically inert and trusted for long-term use in devices like artificial blood vessels.

Its proven biocompatibility in the human body provides powerful evidence of its safety and non-reactivity when used with food.

Key Properties That Enhance Food & Beverage Operations

Beyond its inertness, PTFE possesses several physical properties that make it highly advantageous for the demanding environment of food and beverage production.

The Non-Stick Advantage

PTFE is famous for its non-stick surface. In an industrial setting, this quality prevents food products from adhering to machinery, which simplifies cleaning processes.

Easier cleaning helps reduce the risk of bacterial growth on equipment surfaces, contributing to overall food safety and operational hygiene.

High-Temperature Stability

PTFE can withstand the high temperatures common in cooking, baking, and sterilization processes without degrading.

This thermal resistance ensures the material maintains its structural integrity and safety profile even during intensive food production cycles.

Durability and Wear Resistance

Components made from PTFE, such as seals, gaskets, and pipe liners, are highly durable. They can withstand repeated use, abrasive cleaning, and mechanical stress.

This resilience reduces the need for frequent part replacement and minimizes the risk of material failure that could compromise a production line.

Understanding the Trade-offs and Considerations

While PTFE is exceptionally safe, it's important to understand the context of its use to ensure maximum safety and performance.

The Importance of "Food-Grade" Certification

Not all PTFE is created equal. For any food or beverage application, it is critical to use only certified food-grade PTFE.

Industrial grades may contain additives or be manufactured under conditions that are not suitable for food contact. Always verify the material's certification.

Avoiding Extreme Overheating

While highly heat-resistant, PTFE does have temperature limits. Subjecting the material to extreme temperatures beyond its specification can cause it to break down.

In food processing environments, operating within the material's established thermal limits is essential for maintaining its integrity and safety.

Making the Right Choice for Your Goal

To apply this knowledge, consider how PTFE's specific attributes align with your primary operational needs.

- If your primary focus is product purity: PTFE's unmatched chemical inertness is its greatest asset, guaranteeing no interaction with your food or beverage.

- If your primary focus is operational hygiene: Its non-stick surface simplifies cleaning protocols and minimizes the potential for microbial contamination on equipment.

- If your primary focus is equipment reliability: The material's durability and resistance to both high temperatures and wear make it a dependable choice for critical components.

Ultimately, PTFE's unique combination of chemical stability, physical performance, and regulatory approval makes it a cornerstone material for safety in the food and beverage industry.

Summary Table:

| Key Property | Benefit for Food & Beverage Applications |

|---|---|

| Chemical Inertness | Prevents chemical reactions, ensuring no leaching or flavor transfer to food. |

| Non-Stick Surface | Simplifies cleaning, reduces bacterial growth, and enhances hygiene. |

| High-Temperature Stability | Withstands cooking, sterilization, and baking processes without degrading. |

| Durability & Wear Resistance | Provides long-lasting performance for seals, gaskets, and liners in demanding environments. |

| FDA Approval | Certified safe for direct food contact, meeting stringent regulatory standards. |

Ensure the highest standards of safety and efficiency in your food and beverage operations with KINTEK's precision PTFE components.

As a trusted manufacturer for the semiconductor, medical, laboratory, and industrial sectors, we specialize in custom PTFE fabrication—from prototypes to high-volume orders. Our components, including seals, liners, and labware, are engineered for chemical inertness, durability, and compliance, helping you maintain product purity and streamline production.

Contact us today to discuss your specific needs and learn how our solutions can enhance your application!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation