At its core, the problem with Polytetrafluoroethylene (PTFE) is not the finished, solid material itself under normal conditions, but its inseparable link to a class of toxic “forever chemicals” known as PFAS. The controversy arises from the entire lifecycle of PTFE—from the chemicals used in its production to the byproducts created upon its disposal—which creates significant environmental and health risks that contradict its image as a safe, inert product.

The central conflict is this: While the solid PTFE used in products like non-stick pans or industrial seals is chemically stable and safe during proper use, its manufacturing and disposal processes rely on and release harmful PFAS compounds that persist indefinitely in the environment.

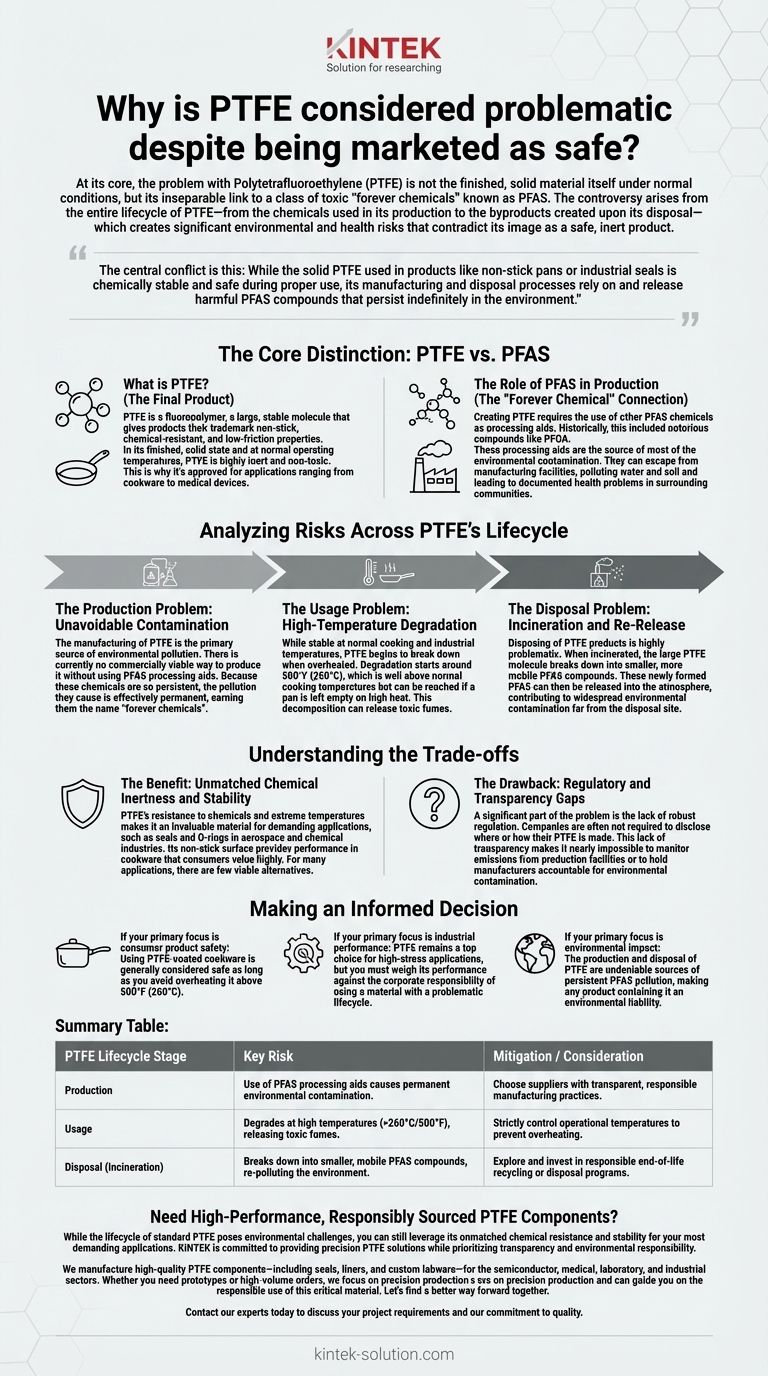

The Core Distinction: PTFE vs. PFAS

To understand the risk, it's crucial to distinguish between the final product and the chemicals used to create it. PTFE is technically a type of PFAS, but the primary concern revolves around the smaller, more mobile PFAS chemicals used as processing aids.

What is PTFE? (The Final Product)

PTFE is a fluoropolymer, a large, stable molecule that gives products their trademark non-stick, chemical-resistant, and low-friction properties.

In its finished, solid state and at normal operating temperatures, PTFE is highly inert and non-toxic. This is why it's approved for applications ranging from cookware to medical devices.

The Role of PFAS in Production (The "Forever Chemical" Connection)

Creating PTFE requires the use of other PFAS chemicals as processing aids. Historically, this included notorious compounds like PFOA.

These processing aids are the source of most of the environmental contamination. They can escape from manufacturing facilities, polluting water and soil and leading to documented health problems in surrounding communities.

Analyzing Risks Across PTFE's Lifecycle

The safety of PTFE cannot be judged by the final product alone. A clear-eyed assessment requires looking at every stage of its existence, from creation to disposal.

The Production Problem: Unavoidable Contamination

The manufacturing of PTFE is the primary source of environmental pollution. There is currently no commercially viable way to produce it without using PFAS processing aids.

Because these chemicals are so persistent, the pollution they cause is effectively permanent, earning them the name "forever chemicals."

The Usage Problem: High-Temperature Degradation

While stable at normal cooking and industrial temperatures, PTFE begins to break down when overheated.

Degradation starts around 500°F (260°C), which is well above normal cooking temperatures but can be reached if a pan is left empty on high heat. This decomposition can release toxic fumes.

The Disposal Problem: Incineration and Re-Release

Disposing of PTFE products is highly problematic. When incinerated, the large PTFE molecule breaks down into smaller, more mobile PFAS compounds.

These newly formed PFAS can then be released into the atmosphere, contributing to widespread environmental contamination far from the disposal site.

Understanding the Trade-offs

PTFE remains in widespread use because its unique properties are difficult to replicate. This creates a classic trade-off between high performance and significant environmental risk.

The Benefit: Unmatched Chemical Inertness and Stability

PTFE's resistance to chemicals and extreme temperatures makes it an invaluable material for demanding applications, such as seals and O-rings in aerospace and chemical industries.

Its non-stick surface provides performance in cookware that consumers value highly. For many applications, there are few viable alternatives.

The Drawback: Regulatory and Transparency Gaps

A significant part of the problem is the lack of robust regulation. Companies are often not required to disclose where or how their PTFE is made.

This lack of transparency makes it nearly impossible to monitor emissions from production facilities or to hold manufacturers accountable for environmental contamination.

Making an Informed Decision

Understanding the full lifecycle of PTFE is key to assessing its risk. Your conclusion about its safety depends entirely on the context of your concern.

- If your primary focus is consumer product safety: Using PTFE-coated cookware is generally considered safe as long as you avoid overheating it above 500°F (260°C).

- If your primary focus is industrial performance: PTFE remains a top choice for high-stress applications, but you must weigh its performance against the corporate responsibility of using a material with a problematic lifecycle.

- If your primary focus is environmental impact: The production and disposal of PTFE are undeniable sources of persistent PFAS pollution, making any product containing it an environmental liability.

Ultimately, the safety of PTFE is a paradox, where a stable and useful final product is created and destroyed by means of an environmentally hazardous process.

Summary Table:

| PTFE Lifecycle Stage | Key Risk | Mitigation / Consideration |

|---|---|---|

| Production | Use of PFAS processing aids causes permanent environmental contamination. | Choose suppliers with transparent, responsible manufacturing practices. |

| Usage | Degrades at high temperatures (>260°C/500°F), releasing toxic fumes. | Strictly control operational temperatures to prevent overheating. |

| Disposal (Incineration) | Breaks down into smaller, mobile PFAS compounds, re-polluting the environment. | Explore and invest in responsible end-of-life recycling or disposal programs. |

Need High-Performance, Responsibly Sourced PTFE Components?

While the lifecycle of standard PTFE poses environmental challenges, you can still leverage its unmatched chemical resistance and stability for your most demanding applications. KINTEK is committed to providing precision PTFE solutions while prioritizing transparency and environmental responsibility.

We manufacture high-quality PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, we focus on precision production and can guide you on the responsible use of this critical material.

Let's find a better way forward together. Contact our experts today to discuss your project requirements and our commitment to quality.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- How does PFA compare to FEP in terms of heat resistance and environmental effects? Choose the Right Fluoropolymer

- What makes PTFE suitable for piping and tubing systems? Unlock Superior Chemical Resistance and Durability

- What does PTFE stand for? The Science Behind the Super-Material

- What chemicals is PTFE resistant to? Discover Its Near-Universal Chemical Inertness

- What are the limitations of PTFE in its applications? Understanding Its Mechanical Weaknesses

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What are the thermal properties of Teflon? Unmatched Stability from Extreme Heat to Cryogenic Cold

- How is Teflon used in the textile industry? Creating Stain-Resistant, Water-Repellent Fabrics