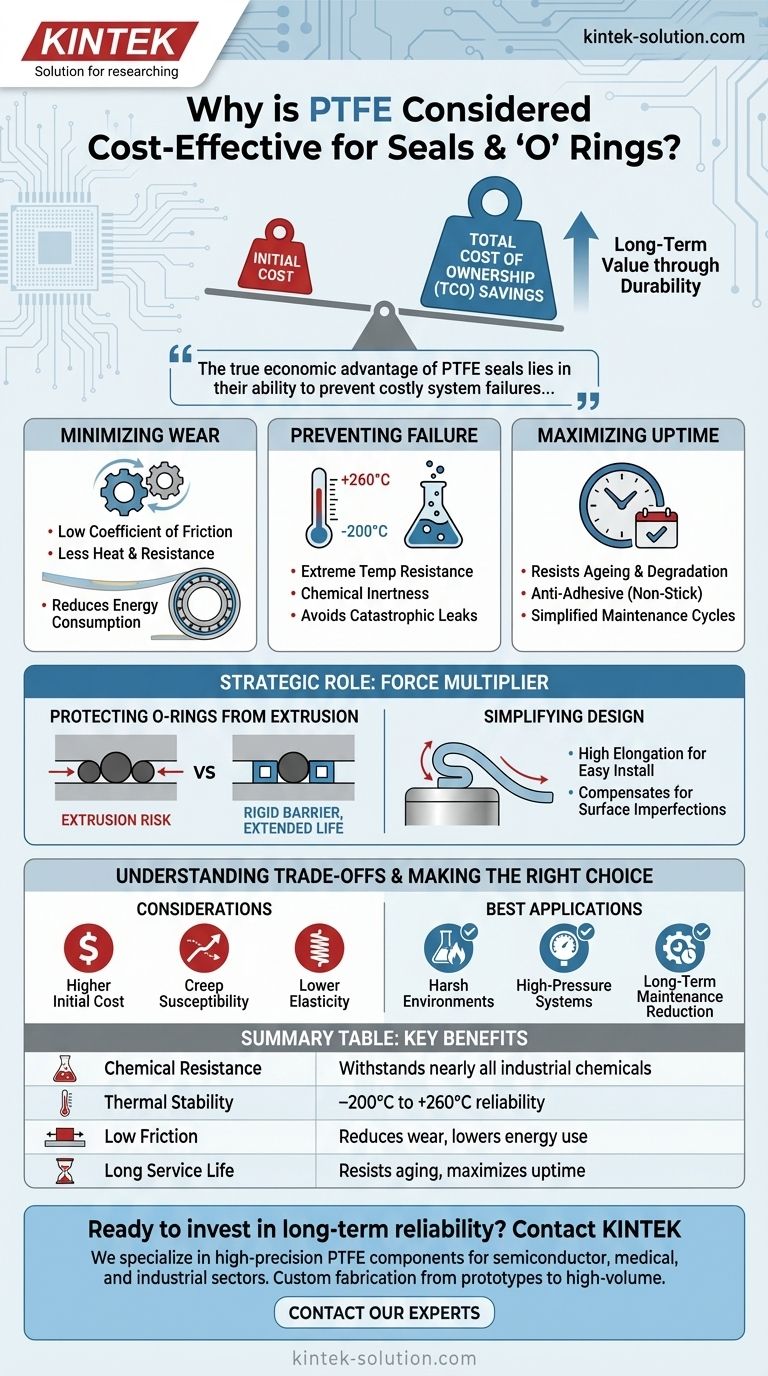

To be clear, PTFE's cost-effectiveness is not about a low initial purchase price compared to basic elastomers. Its value comes from its remarkably low total cost of ownership, driven by exceptional durability, chemical resistance, and thermal stability that dramatically reduce failure rates, maintenance, and equipment downtime.

The true economic advantage of PTFE seals lies in their ability to prevent costly system failures and extend operational life in demanding conditions where lesser materials would quickly degrade, leading to significant long-term savings.

Beyond Upfront Price: How PTFE Lowers Total Cost

The financial calculation for a component like a seal must extend beyond its sticker price. PTFE's unique properties translate directly into tangible savings over the lifecycle of the equipment it protects.

Minimizing Wear with Low Friction

PTFE has an exceptionally low coefficient of friction, especially against metals. This means less resistance, less heat generation, and significantly less wear on both the seal and the machinery's moving parts.

This self-lubricating quality creates a thin film that extends the seal's life and improves the overall efficiency of the system, which can reduce energy consumption over time.

Preventing Failure in Extreme Environments

Many industrial processes involve aggressive chemicals or extreme temperatures that would destroy common sealing materials. PTFE's resistance to these conditions is a primary driver of its cost-effectiveness.

Its ability to withstand nearly all industrial chemicals and operate in a vast temperature range (–200°C to +260°C) prevents premature seal failure, which avoids catastrophic leaks, production halts, and expensive cleanup operations.

Maximizing Uptime Through Longevity

PTFE is highly resistant to ageing and does not become brittle or degrade from exposure to the elements. This inherent stability ensures a long and predictable service life.

Furthermore, its anti-adhesive, non-stick properties prevent residue buildup, which simplifies maintenance and cleaning cycles, keeping equipment running for longer periods without intervention.

The Strategic Role of PTFE as a Force Multiplier

In many applications, PTFE's greatest value is not as the primary seal, but as a critical support component that enhances the entire sealing system.

Protecting O-Rings from Extrusion

Under high pressures and temperatures, standard rubber O-rings can be forced, or "extruded," into the clearance gaps between metal parts, causing them to shear and fail.

A simple PTFE backup ring installed alongside the O-ring provides a rigid barrier that prevents this extrusion. This small addition dramatically extends the life and pressure rating of the entire sealing system, making a simple, inexpensive O-ring viable in a much more demanding application.

Simplifying Design and Installation

PTFE possesses high elongation, which means it can be stretched easily over components during installation without being damaged. This flexibility simplifies assembly, reducing labor time and the risk of incidental damage.

This flexibility also allows it to compensate for minor surface imperfections on mating parts, potentially reducing the need for expensive, high-precision machining.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. An objective analysis requires acknowledging its limitations.

Higher Initial Material Cost

Compared to common elastomers like nitrile or neoprene, PTFE is more expensive on a per-unit basis. Its cost-effectiveness is only realized in applications where its superior performance characteristics are necessary to prevent failure or reduce long-term maintenance.

Susceptibility to Creep

Under a constant, sustained load, PTFE can be subject to "creep" or "cold flow," where the material slowly deforms over time. This must be accounted for in the design of the seal gland to ensure long-term sealing pressure is maintained.

Lower Elasticity

PTFE is a relatively rigid plastic, not a rubbery elastomer. It does not have the "bounce-back" or elastic memory of a material like a rubber O-ring. This is precisely why it works so well as a backup ring but may be unsuitable as a standalone dynamic seal in some situations.

Making the Right Choice for Your Application

Selecting the right seal is about matching the material's properties to the operational demands and financial goals of the project.

- If your primary focus is reliability in harsh chemical or thermal environments: PTFE is the superior choice, as its resistance prevents costly failures and downtime that would quickly erase any savings from a cheaper material.

- If your primary focus is extending the life of high-pressure systems: Using PTFE as backup rings is a highly cost-effective strategy to protect primary elastomeric seals from extrusion failure.

- If your primary focus is reducing long-term maintenance and energy costs: PTFE's low-friction properties minimize component wear and improve mechanical efficiency, delivering savings over the equipment's entire lifespan.

Ultimately, choosing PTFE is an investment in operational stability and long-term reliability.

Summary Table:

| Key Factor | Benefit |

|---|---|

| Chemical Resistance | Withstands nearly all industrial chemicals, preventing failure and leaks. |

| Thermal Stability | Operates from -200°C to +260°C, ensuring reliability in extreme environments. |

| Low Friction | Reduces wear on components and can lower energy consumption. |

| Long Service Life | Resists aging and degradation, maximizing equipment uptime. |

Ready to invest in long-term reliability and reduce your total cost of ownership?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services—from prototypes to high-volume orders—ensure you get the exact PTFE solution your application demands.

Contact our experts today to discuss how our PTFE components can enhance your system's performance and deliver significant long-term savings.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the primary characteristics of PTFE seals? Unmatched Performance for Extreme Conditions

- Why are PTFE seals preferred over traditional rubber seals? Superior Performance in Extreme Conditions