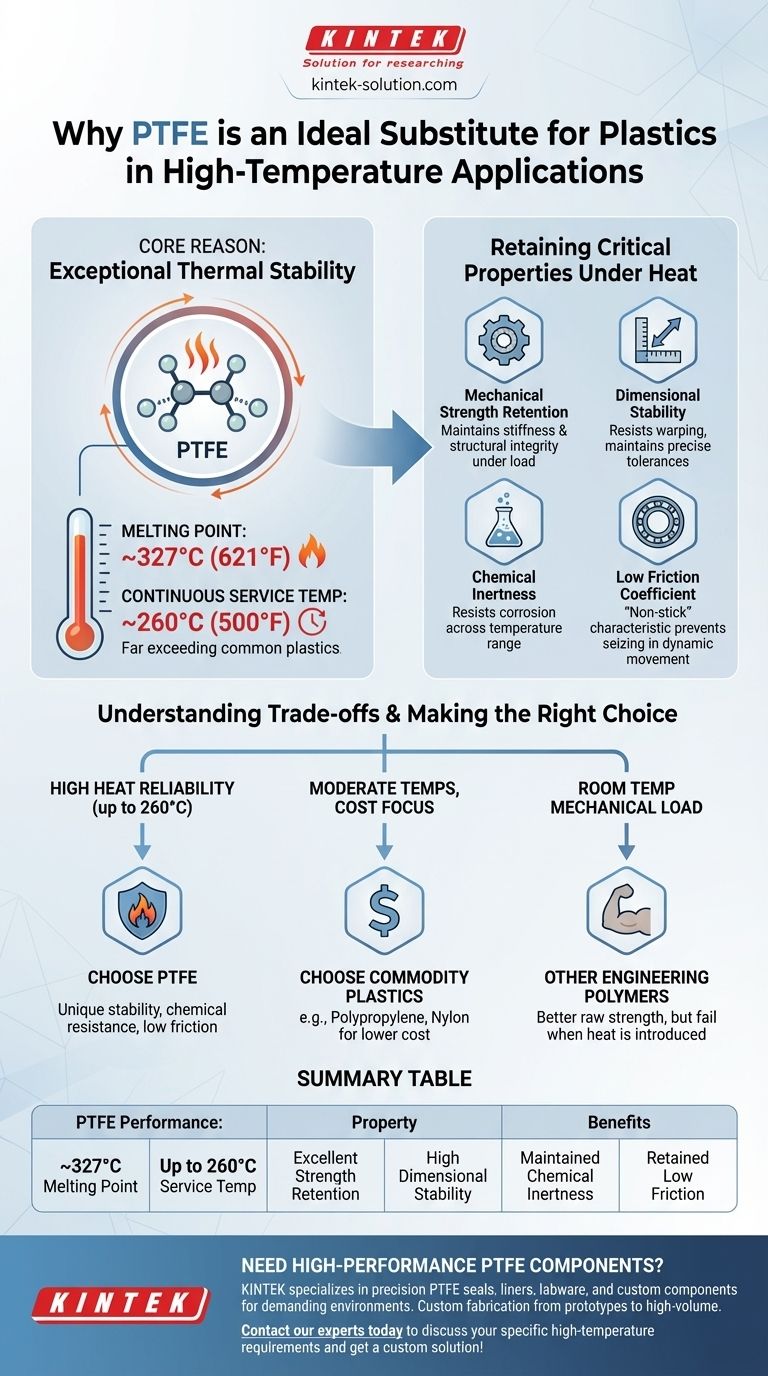

At its core, PTFE (Polytetrafluoroethylene) is considered an ideal substitute for other plastics in high-temperature applications because of its exceptional thermal stability. It possesses a very high melting point of approximately 327°C (621°F) and can operate continuously at temperatures up to 260°C (500°F) without degrading or losing its essential mechanical properties.

The true value of PTFE isn't just that it survives high temperatures—it's that it continues to perform reliably under those conditions. Where other plastics warp, weaken, or fail, PTFE maintains its strength, dimensional stability, and chemical inertness.

The Foundation: Exceptional Thermal Stability

The primary reason engineers turn to PTFE is its ability to handle heat in a way most other polymers cannot. This capability stems from two key thermal characteristics.

The High Melting Point

PTFE has an absolute melting point of around 327°C (621°F). This is the temperature at which it transitions from a solid to a liquid, and it stands significantly higher than commodity plastics like polyethylene or polypropylene.

This high threshold makes it a direct replacement for weaker plastics that would simply melt in demanding thermal environments.

The High Continuous Service Temperature

More important for practical applications is the continuous service temperature, which for PTFE is approximately 260°C (500°F). This is the maximum temperature the material can withstand for extended periods without significant loss of its properties.

It's this reliable, long-term performance that distinguishes PTFE in applications involving repeated exposure to extreme heat.

How PTFE Retains Critical Properties Under Heat

Surviving high temperatures is only part of the equation. The key to PTFE's success is its ability to retain the specific engineering properties that made it desirable in the first place, even when heated.

Maintaining Mechanical Strength

Many plastics soften and lose their structural integrity as temperatures rise. PTFE, however, retains its stiffness and strength at abusive temperatures.

This allows components like seals and bushings to continue functioning under mechanical load without failing.

Ensuring Dimensional Stability

Thermal expansion can cause components to warp or change size, leading to system failure. PTFE exhibits excellent dimensional stability, meaning it resists deformation even when subjected to significant heat.

This property is critical for maintaining precise tolerances in parts like high-performance seals and bushings.

Preserving Chemical Inertness

High temperatures can often accelerate chemical reactions and degradation. PTFE is famously chemically inert, and it maintains this resistance across its entire operating temperature range.

This makes it ideal for containers or linings that transport hot, corrosive materials.

Retaining Low Friction

PTFE is well-known for its extremely low coefficient of friction. Crucially, this "non-stick" characteristic remains effective at high temperatures, ensuring components can move freely without seizing.

This is a key advantage for dynamic applications like high-temperature bearings or shaft seals.

Understanding the Trade-offs

While PTFE's thermal performance is elite, it is not the default choice for every application. Its unique properties come with practical considerations.

Higher Material Cost

PTFE is a specialty polymer and is significantly more expensive than common, low-cost plastics. Its use is justified when the performance demands, particularly temperature resistance, exceed the capabilities of less expensive alternatives.

Processing Challenges

Due to its high melting temperature and high melt viscosity, PTFE can be more difficult to process using conventional thermoplastic methods like injection molding. This often requires specialized manufacturing techniques, which can impact production costs and design complexity.

Room-Temperature Mechanical Properties

While PTFE's high-temperature performance is its main advantage, other engineering plastics may offer superior hardness, tensile strength, or creep resistance at room temperature. The decision to use PTFE is almost always driven by the need for performance in extreme environments where those other materials would fail.

Making the Right Choice for Your Application

Selecting the right material requires balancing performance needs with cost and manufacturing realities. PTFE stands out as a problem-solver for the most demanding thermal challenges.

- If your primary focus is reliability in extreme heat (up to 260°C / 500°F): PTFE is often the benchmark material, providing a unique combination of thermal stability, chemical resistance, and low friction.

- If your primary focus is cost-effectiveness for moderate temperatures: Commodity plastics like polypropylene or nylon may offer sufficient performance at a much lower cost.

- If you require structural integrity under high mechanical load at room temperature: Other engineering polymers might provide better raw strength, but they will not match PTFE's stability when heat is introduced.

Ultimately, PTFE is chosen when the operational environment is simply too harsh for conventional plastics to survive.

Summary Table:

| Key Property | PTFE Performance | Benefit in High-Temperature Applications |

|---|---|---|

| Melting Point | ~327°C (621°F) | Does not melt or degrade like common plastics |

| Continuous Service Temperature | Up to 260°C (500°F) | Reliable long-term performance in extreme heat |

| Mechanical Strength Retention | Excellent | Maintains stiffness and structural integrity |

| Dimensional Stability | High | Resists warping and deformation |

| Chemical Inertness | Maintained across temp range | Resists corrosive materials even when hot |

| Low Friction Coefficient | Retained at high temps | Prevents seizing in dynamic applications |

Need high-performance PTFE components that won't fail under extreme heat?

At KINTEK, we specialize in precision manufacturing of PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your parts maintain critical properties like thermal stability, chemical resistance, and dimensional accuracy—even in the most demanding environments.

We offer custom fabrication from prototypes to high-volume orders, delivering the reliability your application demands.

Contact our experts today to discuss your specific high-temperature requirements and get a custom solution!

Visual Guide

Related Products

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What chemicals is Teflon resistant to? The Ultimate Guide to PTFE Chemical Inertness

- What aerospace applications use Teflon? Unlock Reliability in Extreme Environments

- Why is PTFE considered versatile? A Material That Excels in Chemical, Thermal, and Frictional Resistance

- What are the main material characteristics of PTFE? Unlock Superior Performance in Extreme Environments

- Is PTFE safe for use in cooking equipment? Modern Non-Stick Cookware Safety Explained

- What is the electrical insulation capability of PTFE? Unmatched Reliability for Demanding Applications

- What are some additional physical properties of PTFE? Beyond Non-Stick: Discover PTFE's Elite Thermal & Chemical Resistance

- How is PTFE used in the food and beverage industry? Ensuring Purity and Efficiency in Production