To be precise, Polytetrafluoroethylene (PTFE) is a preferred material for high-temperature butterfly valves due to its exceptional thermal stability. Unlike many other materials, PTFE maintains its structural integrity, chemical inertness, and sealing performance at continuous operating temperatures up to 260°C (410°F), preventing degradation and failure in demanding industrial environments.

The core reason for selecting PTFE is not just its heat resistance alone, but its unique combination of thermal stability, chemical inertness, and mechanical reliability. This synergy ensures the valve functions safely and effectively under conditions where heat, pressure, and corrosive media are all present.

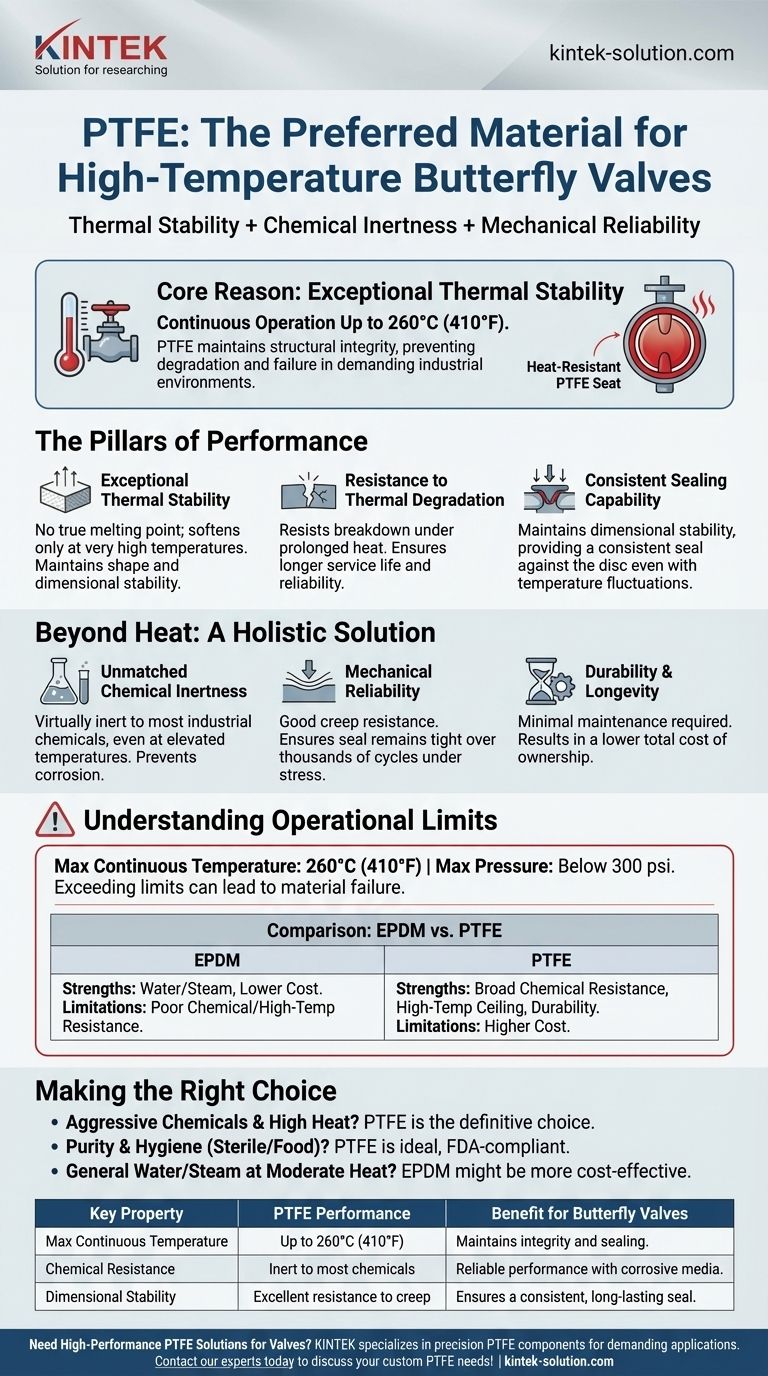

The Pillars of PTFE's High-Temperature Performance

To understand why PTFE is so reliable in heated applications, we must look at a few key physical and mechanical properties that work in concert.

Exceptional Thermal Stability

PTFE does not have a true melting point; instead, it softens at very high temperatures. This allows it to maintain its shape and dimensional stability without deforming or failing in environments where other polymers would warp or melt.

This stability is critical for a butterfly valve's seat, which must maintain its precise shape to create a tight seal against the disc.

Resistance to Thermal Degradation

Many materials break down chemically when exposed to high heat over long periods. PTFE resists this thermal degradation, ensuring it doesn't become brittle or lose its essential properties.

This quality translates directly to a longer service life and greater reliability, reducing the need for frequent maintenance or replacement.

Consistent Sealing Capability

The primary function of a valve seat is to seal. High temperatures can cause materials to expand or contract, compromising this seal.

Because PTFE maintains its dimensional stability under heat, it provides a consistent and reliable sealing force against the valve disc, even as operating temperatures fluctuate.

Beyond Heat: Why PTFE is a Holistic Solution

In most industrial processes, high temperature is just one of several challenges. PTFE's value comes from its ability to handle multiple harsh conditions simultaneously.

Unmatched Chemical Inertness

High-temperature applications, such as those in chemical processing or petrochemicals, often involve highly corrosive substances. PTFE is virtually inert to almost all industrial chemicals.

This means it will not corrode or react when exposed to aggressive media, even at elevated temperatures, making it a uniquely safe and durable choice.

Mechanical Reliability

A valve seat is constantly under compressive stress. PTFE exhibits good resistance to creep—the tendency of a material to slowly deform under a constant load.

This property ensures the seal remains tight and effective over thousands of cycles, even under the combined stress of system pressure and high temperature.

Durability and Longevity

The combination of thermal, chemical, and mechanical resilience makes PTFE-lined valves exceptionally durable. They require minimal maintenance and offer a long service life, which results in a lower total cost of ownership.

Understanding the Operational Limits

While highly capable, PTFE is not a universal solution. Understanding its limitations is critical for proper application and system safety.

Specific Temperature and Pressure Boundaries

Standard PTFE is generally rated for temperatures up to 260°C (410°F) and pressures below 300 psi. Exceeding these limits can lead to material failure and compromise the valve's integrity.

It is crucial to select the valve based on the specific operating conditions of your system, not just the general capabilities of the material.

Comparison to Other Materials

Other elastomers like EPDM have their own strengths, such as excellent resistance to water and steam. However, they do not offer the same broad chemical resistance or high-temperature ceiling as PTFE.

The choice between materials always depends on the specific media, temperature, and pressure demands of the application.

Making the Right Choice for Your Application

Selecting the correct valve material requires a clear understanding of your primary operational goal.

- If your primary focus is handling aggressive chemicals at high temperatures: PTFE is the definitive choice due to its combined thermal stability and chemical inertness.

- If your primary focus is purity and hygiene in sterile, high-heat processes: PTFE's non-contaminating, FDA-compliant properties make it ideal for pharmaceutical or food and beverage applications.

- If your primary focus is general water or steam service at moderate temperatures: A material like EPDM may be a more cost-effective and suitable choice.

Ultimately, a confident decision comes from matching the unique strengths of the material to the precise demands of your application.

Summary Table:

| Key Property | PTFE Performance | Benefit for Butterfly Valves |

|---|---|---|

| Max Continuous Temperature | Up to 260°C (410°F) | Maintains integrity and sealing in high-heat environments. |

| Chemical Resistance | Inert to most chemicals | Performs reliably with corrosive media at high temperatures. |

| Dimensional Stability | Excellent resistance to creep and deformation | Ensures a consistent, long-lasting seal against the valve disc. |

Need a High-Performance PTFE Solution for Your Valves?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom parts—for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

Our expertise ensures your butterfly valves and other critical equipment benefit from PTFE's superior thermal stability and chemical inertness. We offer custom fabrication from prototypes to high-volume orders, guaranteeing a perfect fit and optimal performance for your specific operating conditions.

Enhance your system's reliability and longevity. Contact our experts today to discuss your custom PTFE needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the benefits of using Teflon encapsulated silicone o-rings? Achieve Unmatched Sealing in Harsh Environments

- How does temperature tolerance differ between NBR and PTFE seat materials? A Guide to Extreme Conditions

- What materials are used to make PTFE rotary lip seals? An Inside Look at Their Engineered Design

- What are the main advantages of PTFE gaskets over ordinary rubber gaskets? Superior Chemical & Thermal Resistance

- How do Teflon sheets protect garments during heat transfers? Essential Guide for Flawless Results

- What are the different types of PTFE diaphragms and their applications? Optimize Your Chemical Processing System

- What temperature range can PTFE rotary shaft seals withstand? Operate from -200°C to +260°C

- What types of chemical solutions are PTFE control valves suitable for? Handle Corrosive Acids, Bases & More