The exceptional chemical resistance of PTFE (Polytetrafluoroethylene) is a direct result of its unique molecular structure. The polymer is built from a chain of carbon atoms completely surrounded by a sheath of fluorine atoms, creating incredibly strong and stable carbon-fluorine (C-F) bonds. These bonds are so powerful that they prevent virtually all common acids, bases, solvents, and industrial chemicals from reacting with the material, rendering it almost universally inert.

PTFE's value comes from its molecular architecture. The powerful bond between carbon and fluorine creates a non-reactive shield, making it the default material for components that must survive direct, prolonged contact with the most aggressive chemicals.

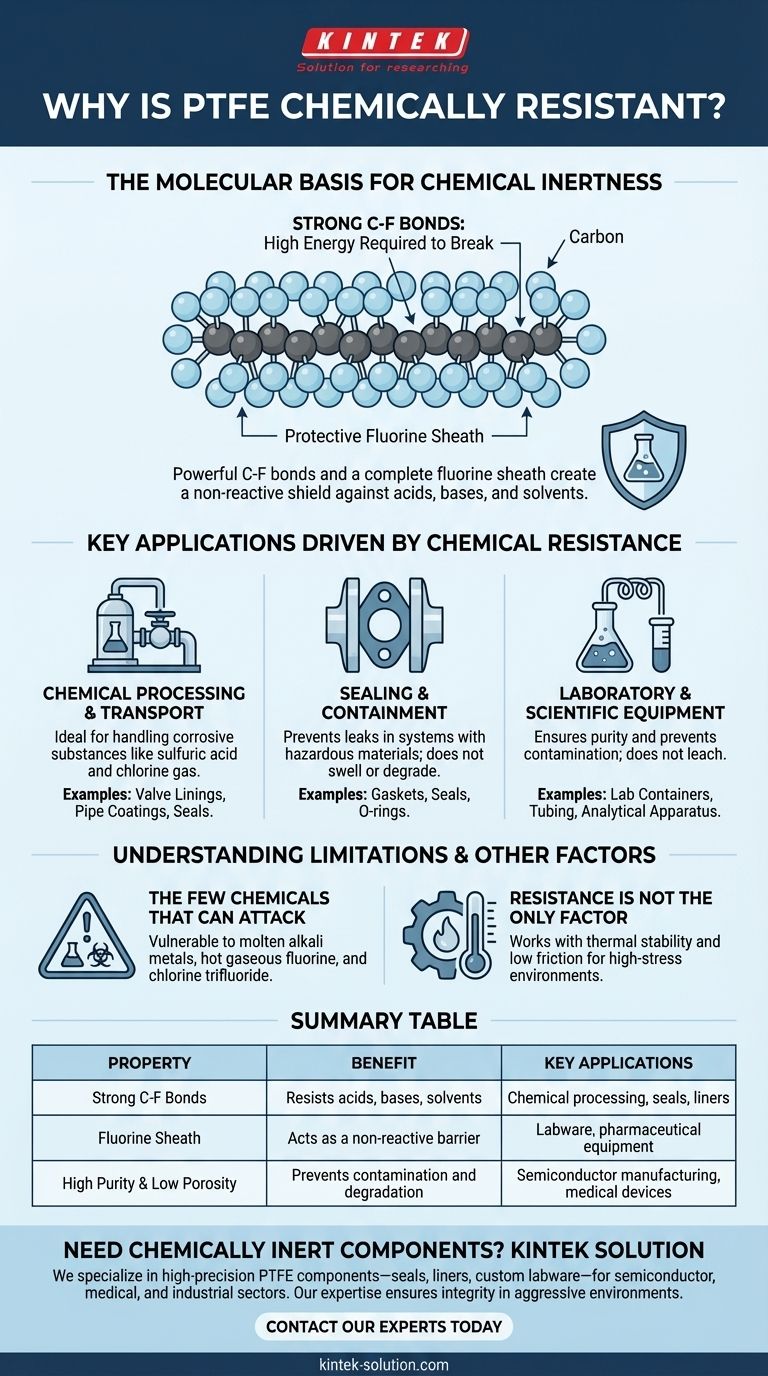

The Molecular Basis for Chemical Inertness

To understand why PTFE is so reliable in harsh environments, we must look at its structure. Its resistance isn't a surface-level feature; it is fundamental to the material itself.

The Strength of the Carbon-Fluorine Bond

The bond between carbon and fluorine is one of the strongest single bonds in organic chemistry. This immense strength requires a huge amount of energy to break, which is why most chemicals simply lack the power to initiate a reaction with PTFE.

This stability persists even at high temperatures and pressures, where other polymers would quickly degrade.

A Protective Fluorine Sheath

In the PTFE polymer, the carbon backbone is completely encased by fluorine atoms. This creates a dense, uniform "sheath" of fluorine that acts as a physical and electrical barrier.

Think of it as a form of molecular armor. Aggressive chemicals can't find a weak point to attack the more vulnerable carbon chain underneath.

High Purity and Low Porosity

PTFE is a highly pure polymer with very low porosity. This means there are few, if any, sites for chemicals to become trapped and initiate degradation over time.

Its non-porous and smooth surface also contributes to its low coefficient of friction, further preventing substances from adhering to and reacting with it.

Key Applications Driven by Chemical Resistance

The near-total chemical inertness of PTFE makes it indispensable in industries where material failure is not an option. Its performance directly translates to safety, purity, and longevity.

Chemical Processing and Transport

In chemical plants, equipment must handle substances like concentrated sulfuric acid, chlorine gas, and other powerful oxidants. PTFE is the material of choice for this.

It is used for valve linings, pipe coatings, and seals to ensure that corrosive fluids can be managed safely without destroying the infrastructure.

Sealing and Containment

Gaskets and seals made from PTFE are critical for preventing leaks in systems handling hazardous or highly reactive materials.

Because PTFE does not swell, dissolve, or break down when exposed to solvents and chemicals, it maintains a reliable seal, ensuring both operational safety and environmental protection.

Laboratory and Scientific Equipment

In a laboratory setting, preventing contamination is paramount. The inertness of PTFE ensures that it will not react with or leach into the samples it contains.

This makes it ideal for lab containers, tubing, and other apparatus where process purity is essential for accurate results.

Understanding the Limitations

While its resistance is remarkable, PTFE is not invincible. An objective assessment requires acknowledging the few specific conditions and substances that can affect it.

The Few Chemicals That Can Attack PTFE

PTFE's inertness has very few exceptions. It is vulnerable to attack by highly reactive substances like molten alkali metals (e.g., sodium), hot gaseous fluorine, and potent agents like chlorine trifluoride.

For nearly all other industrial applications involving common acids, bases, and solvents, these limitations are not a concern.

Resistance is Not the Only Factor

While chemical resistance is its standout property, other characteristics like its thermal stability and low coefficient of friction often work in tandem.

For example, its low friction reduces the chance of abrasive wear, which could otherwise create sites for chemical attack. Its ability to withstand high heat ensures its chemical resistance doesn't falter in demanding processes.

Making the Right Choice for Your Application

Selecting a material requires a clear understanding of the operational environment. PTFE should be your primary candidate when chemical survival is the main challenge.

- If your primary focus is handling highly corrosive acids, bases, or solvents: PTFE is one of the most reliable and durable materials available for components like valve linings, seals, and gaskets.

- If your primary focus is ensuring process purity and preventing contamination: PTFE's inertness makes it an excellent choice for laboratory equipment and systems in the food, beverage, and pharmaceutical industries.

- If your primary focus is reliability under combined chemical and thermal stress: PTFE's ability to maintain its integrity at high temperatures makes it superior to many other polymers in harsh processing environments.

Ultimately, choosing PTFE is an investment in stability and safety where chemical exposure is a constant threat.

Summary Table:

| Property | Benefit | Key Applications |

|---|---|---|

| Strong C-F Bonds | Resists acids, bases, solvents | Chemical processing, seals, liners |

| Fluorine Sheath | Acts as a non-reactive barrier | Labware, pharmaceutical equipment |

| High Purity & Low Porosity | Prevents contamination and degradation | Semiconductor manufacturing, medical devices |

Need chemically inert components that guarantee safety and purity?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, and industrial sectors. Our expertise ensures your equipment withstands the most aggressive chemicals while maintaining integrity from prototype to high-volume production.

Contact our experts today to discuss your specific requirements and discover how our PTFE solutions can enhance your operational reliability.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- How are fillers used to enhance PTFE properties? Boost Wear, Strength, and Thermal Performance

- How does PTFE function as a lubricant? Master Low-Friction Performance in Harsh Environments

- Why is Teflon a good electrical insulator? Unmatched Performance for Demanding Applications

- Why is PTFE considered chemically resistant? The Science Behind Its Unmatched Inertness

- What are the thermal properties of PTFE? A Guide to Its High-Temperature Limits and Trade-offs

- What is the temperature range for PTFE applications? Choose the Right Grade for Your High-Temp Needs

- What is a unique frictional characteristic of PTFE? Discover its near-total absence of stick-slip

- How was PTFE discovered and developed? From Lab Accident to Essential High-Performance Polymer