To put it directly, Polytetrafluoroethylene (PTFE) is an ideal material for bellows because it uniquely combines extreme chemical inertness and high-purity properties with outstanding mechanical flexibility and durability. Its ability to withstand repeated compression, flexing, and exposure to harsh environments without degrading or contaminating the system makes it a definitive choice for critical applications in the medical, aerospace, and chemical processing industries.

The core reason PTFE excels for bellows is not a single feature, but its rare synergy of properties. It solves the simultaneous need for a seal that is both dynamically flexible and chemically indestructible, a combination most other materials cannot offer.

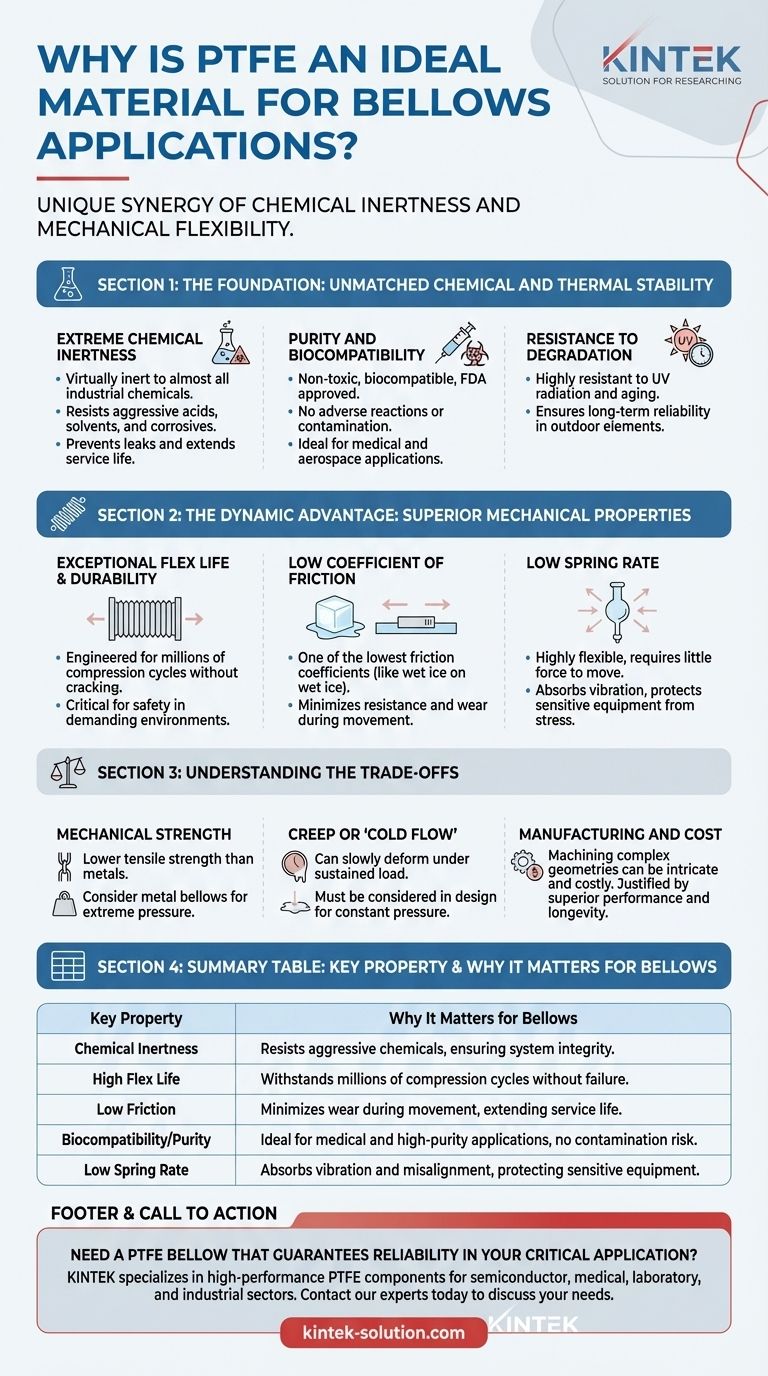

The Foundation: Unmatched Chemical and Thermal Stability

The primary function of a bellow is often to create a seal in a dynamic environment. PTFE provides an unparalleled level of stability, ensuring the integrity of the system it protects.

Extreme Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals. This makes PTFE bellows essential for applications involving aggressive acids, solvents, or corrosive materials where other elastomers or even metals would fail.

This inertness ensures the bellow itself does not degrade, preventing leaks and extending the service life of critical components in chemical processing, oil, and gas systems.

Purity and Biocompatibility

For sensitive applications, purity is non-negotiable. PTFE is non-toxic, biocompatible, and meets FDA approval standards, meaning it will not cause adverse reactions or leach contaminants.

This makes it the default choice for medical equipment like bio-containment vessels and syringe components. Its low outgassing properties also make it vital for contamination-free fluid transfer in aerospace fuel systems.

Resistance to Degradation

Unlike many plastics or rubbers, PTFE is highly resistant to degradation from UV radiation (sunlight) and aging. This ensures long-term reliability and performance, especially in components that are exposed to the elements.

The Dynamic Advantage: Superior Mechanical Properties

A bellow must move. PTFE’s mechanical characteristics are perfectly suited for the constant compression, extension, and misalignment that bellows must endure.

Exceptional Flex Life and Durability

PTFE bellows are engineered for a long life under constant movement. This high "flex life" means they can withstand millions of compression cycles without cracking or failing.

This durability is critical for ensuring safety and reliability in applications handling dangerous chemicals or shielding highly sterile areas from the outside environment.

Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "slipperiness" means that as the bellow compresses and extends, the material folds slide against each other with minimal resistance or wear.

This significantly reduces the risk of fatigue damage, minimizes maintenance, and lowers long-term operational costs.

Low Spring Rate

The "spring rate" is the amount of force required to compress or extend a bellow. PTFE naturally has a very low spring rate, meaning it is highly flexible and requires little force to move.

This is a critical advantage when connecting to fragile or stress-sensitive equipment, such as components made of glass or graphite, as the bellow absorbs vibration and misalignment without transferring damaging stress.

Understanding the Trade-offs

While PTFE is an exceptional material, no choice is without context. A complete technical assessment requires acknowledging its limitations.

Considerations for Mechanical Strength

PTFE is a polymer, not a metal. It does not possess the high tensile strength or rigidity of steel or other metal alloys. In applications requiring extreme pressure containment without reinforcement, a metal bellow might be a more suitable choice.

Creep or "Cold Flow"

Under a sustained, heavy load, PTFE can be susceptible to "creep" or cold flow, where the material slowly deforms over time. This must be considered in the design phase for any application involving constant static pressure or load.

Manufacturing and Cost

Machining or molding PTFE into complex bellow geometries can be more intricate and costly than manufacturing simpler bellows from rubber or some metals. This initial cost is typically justified by PTFE's superior performance and longevity in demanding applications.

Making the Right Choice for Your Application

Selecting PTFE is a strategic decision based on the primary demands of your system.

- If your primary focus is handling aggressive chemicals or high-purity fluids: Specify PTFE for its unmatched chemical inertness and non-leaching, biocompatible properties.

- If your primary focus is high-cycle dynamic sealing: Choose PTFE for its exceptional flex life and low coefficient of friction, which ensure durability and reliability over millions of movements.

- If your primary focus is protecting sensitive or fragile equipment: Rely on PTFE for its low spring rate, which effectively absorbs vibration and misalignment without transferring stress.

Ultimately, specifying PTFE for a bellows application is a decision to prioritize long-term reliability and safety in environments where other materials would fail.

Summary Table:

| Key Property | Why It Matters for Bellows |

|---|---|

| Chemical Inertness | Resists virtually all aggressive chemicals, ensuring system integrity. |

| High Flex Life | Withstands millions of compression cycles without failure. |

| Low Friction | Minimizes wear during movement, extending service life. |

| Biocompatibility/Purity | Ideal for medical and high-purity applications, with no contamination risk. |

| Low Spring Rate | Absorbs vibration and misalignment, protecting sensitive equipment. |

Need a PTFE bellow that guarantees reliability in your critical application? KINTEK specializes in manufacturing high-performance PTFE components, including custom bellows, for the semiconductor, medical, laboratory, and industrial sectors. We combine precision production with custom fabrication—from prototypes to high-volume orders—to deliver solutions that meet your exact requirements for chemical resistance, durability, and purity. Contact our experts today to discuss how our PTFE bellows can enhance your system's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What material properties make polymer-plastic ball bearings suitable for diverse industries? Solve Harsh Environment Challenges

- What chemical resistance properties do expanded PTFE gaskets have? Achieve Universal Sealing for Aggressive Chemicals

- What are expanded PTFE gaskets and how are they manufactured? The Secret to Superior Sealing Performance

- What are the main industries that use PTFE lip seals? Solve Extreme Sealing Challenges

- Why is the low friction coefficient of PTFE Teflon washers advantageous? Achieve Peak Efficiency and Durability

- What materials are offered for PTFE bushes? Choose the Right Filled PTFE Compound for Your Application

- What are some application examples of PTFE O-ring seals in mechanical equipment? Solve Extreme Sealing Challenges

- What are the key advantages of using PTFE gaskets and sheets? Superior Sealing for Harsh Environments