Engaging a professional for a custom seal solution is a strategic decision to mitigate risk and ensure operational integrity. While off-the-shelf seals work for standard applications, custom solutions require a deep understanding of material science and mechanical design to function reliably under unique or extreme conditions. Experts provide tailored geometries and material compounds that are specifically engineered to withstand your system's unique temperature, pressure, and chemical exposures.

While a standard seal is a commodity, a custom seal is a critical engineering component. Professional consultation is not about buying a part; it's about investing in a comprehensive analysis of your entire system to prevent costly failure and optimize long-term performance.

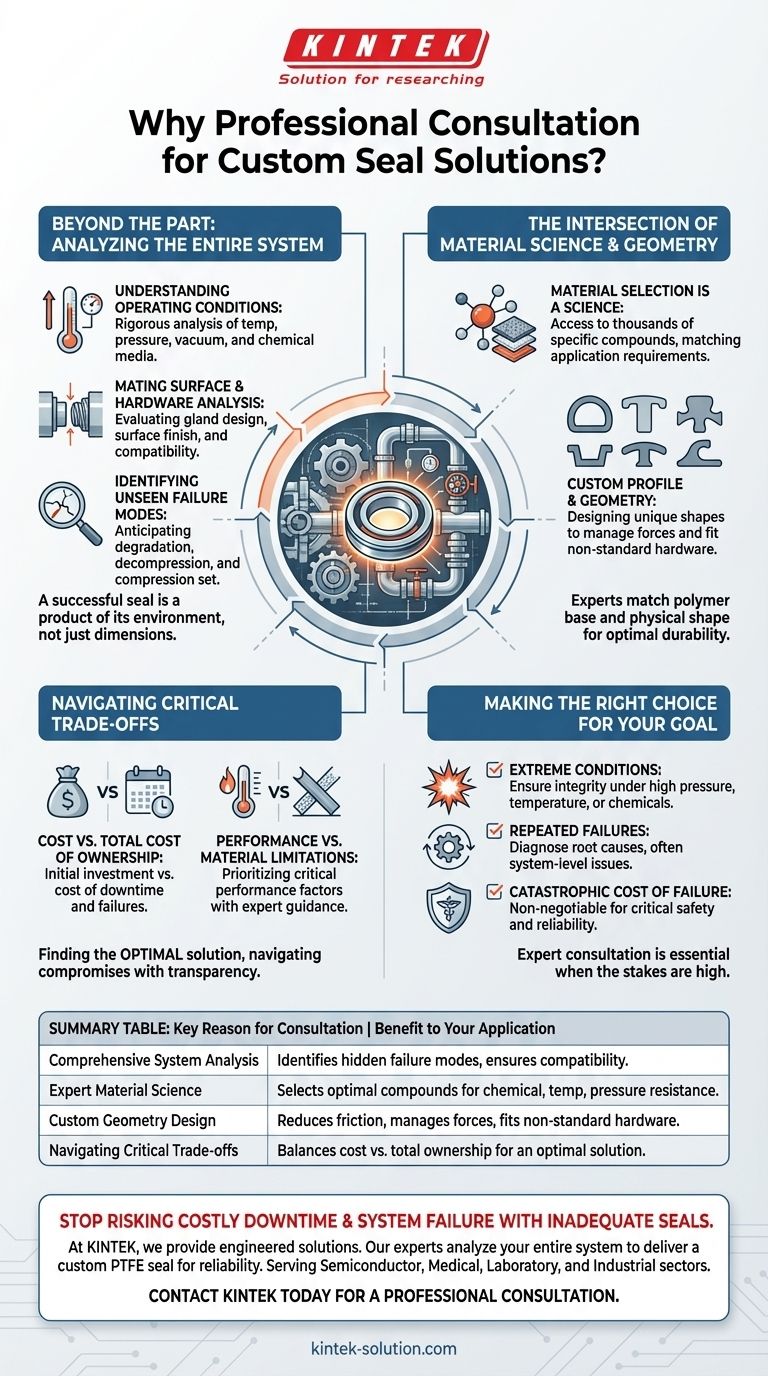

Beyond the Part: Analyzing the Entire System

A successful seal is a product of its environment. A consultant's primary value is their ability to analyze the complete system, not just the seal's immediate dimensions.

Understanding Operating Conditions

An expert conducts a rigorous analysis of all variables. This includes not only maximum temperature and pressure but also pressure cycling, potential for vacuum, and the specific chemical media the seal will contact.

Mating Surface and Hardware Analysis

The performance of a seal is inextricably linked to the hardware it sits in. A consultant will evaluate gland design, surface finish, and the material of the mating components to ensure compatibility and prevent premature wear or leakage paths.

Identifying Unseen Failure Modes

Professionals are trained to anticipate subtle failure modes that a non-specialist might overlook. They can predict risks like chemical degradation, explosive decompression, compression set, or extrusion, and design the seal specifically to prevent them.

The Intersection of Material Science and Geometry

A seal's performance is determined by two factors: its material composition and its physical shape. Experts operate at the precise intersection of these two disciplines.

Material Selection is a Science

Choosing the right material goes far beyond picking a generic type like "Viton" or "Silicone." A specialist has access to thousands of specific compounds, each with a unique performance profile.

They meticulously match the polymer base, cure system, and fillers to your application's exact chemical and thermal requirements, ensuring optimal durability and service life.

Custom Profile and Geometry

A standard O-ring is not always the correct answer. A consultant can design a custom seal profile—such as a D-ring, T-ring, or a completely unique shape—to manage specific forces, reduce friction in dynamic applications, or fit into non-standard hardware.

Understanding the Trade-offs

An effective consultation is not about finding a "perfect" solution but the optimal one. This involves navigating critical trade-offs with transparency.

Cost vs. Total Cost of Ownership

A custom-engineered seal has a higher upfront cost than a standard part. However, this initial investment is often negligible compared to the cost of equipment downtime, lost production, safety incidents, or warranty claims caused by a failed seal.

Performance vs. Material Limitations

No single material excels in all conditions. A material with excellent high-temperature resistance may have poor abrasion characteristics. An expert helps you navigate these compromises, prioritizing the most critical performance factors for your application.

Making the Right Choice for Your Goal

Relying on professional expertise is essential when the stakes are high. Consider a consultation as a mandatory step in these scenarios.

- If your application involves extreme conditions: Consult an expert to ensure material and design integrity under high pressure, temperature, or aggressive chemical exposure.

- If you are experiencing repeated seal failures: A consultation is necessary to diagnose the root cause, which is often a system-level issue rather than just a faulty part.

- If the cost of failure is catastrophic: For critical systems in aerospace, medical, or energy sectors, professional design validation is non-negotiable to ensure safety and reliability.

Ultimately, investing in expert consultation transforms a simple component into a precisely engineered solution that protects your entire system.

Summary Table:

| Key Reason for Consultation | Benefit to Your Application |

|---|---|

| Comprehensive System Analysis | Identifies hidden failure modes and ensures seal compatibility with your hardware. |

| Expert Material Science | Selects from thousands of compounds for optimal chemical, temperature, and pressure resistance. |

| Custom Geometry Design | Creates profiles (D-ring, T-ring, etc.) to reduce friction, manage forces, and fit non-standard hardware. |

| Navigating Critical Trade-offs | Balances cost vs. total ownership and performance vs. material limitations for an optimal solution. |

Stop risking costly downtime and system failure with inadequate seals.

At KINTEK, we don't just sell parts; we provide engineered solutions. Our experts analyze your entire system—from operating conditions and mating surfaces to potential failure modes—to deliver a custom PTFE seal (or other high-performance polymer) designed for reliability and longevity.

We specialize in serving the semiconductor, medical, laboratory, and industrial sectors with precision seals, liners, and labware. Whether you need a prototype or high-volume production, we ensure your custom fabrication is a strategic investment in your operation's integrity.

Contact KINTEK today for a professional consultation and let us engineer the perfect seal solution for your critical application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What types of cutting tools are recommended for machining PTFE? Achieve Clean Cuts and Tight Tolerances

- What makes expanded PTFE suitable for gaskets and sealants? Achieve a Leak-Free Seal in Demanding Applications

- What are the key benefits of using PTFE bellows? Achieve Superior Chemical Resistance and Purity

- What semi-finished products are available in PTFE? Essential Building Blocks for High-Performance Components

- How do PTFE expansion bellows perform under extreme temperature conditions? Ensure System Integrity from -200°C to 260°C

- What makes PTFE envelope gaskets suitable for high-temperature applications? Superior Heat & Chemical Resistance

- What environmental conditions can Teflon seals withstand? Master Extreme Temperatures & Chemicals

- What are the key properties of PTFE that make it suitable for structural bearings? Unlock Superior Load Support & Movement