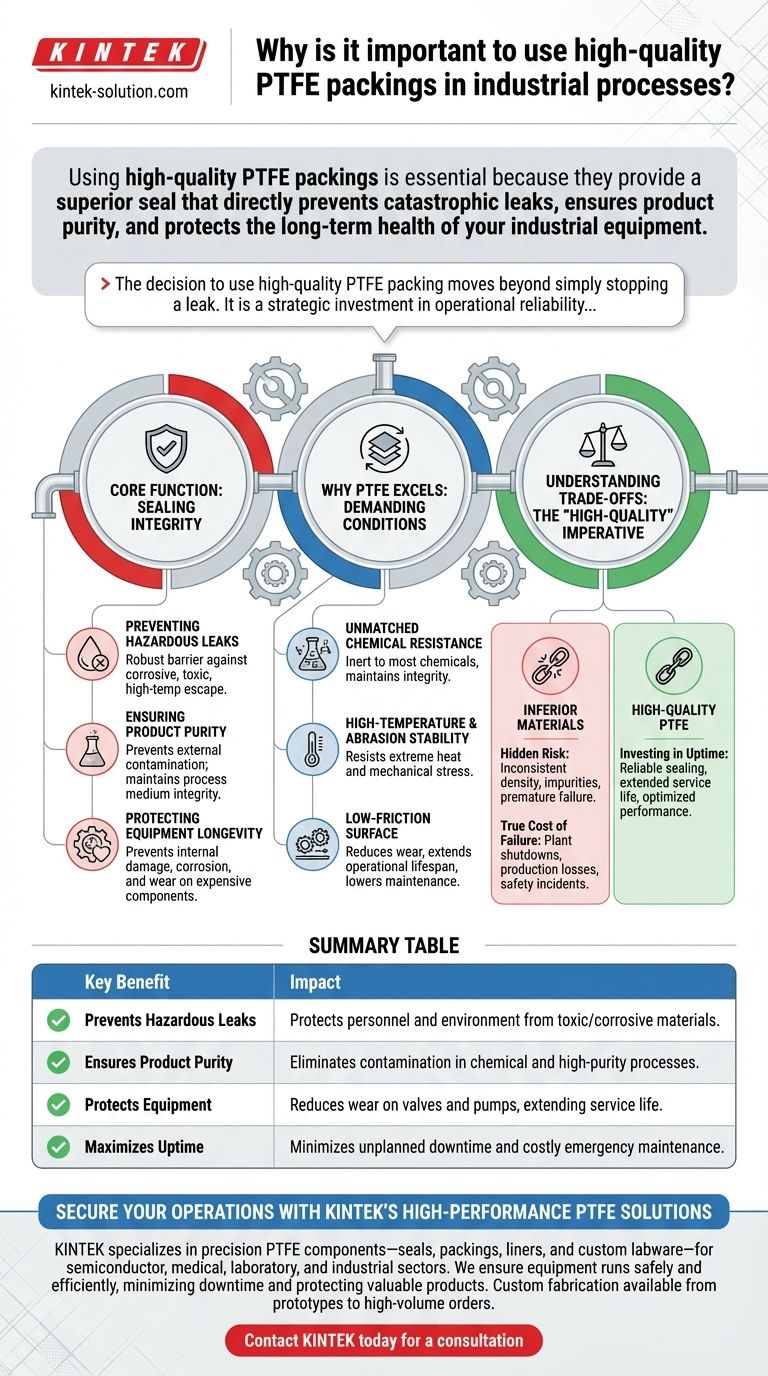

Using high-quality PTFE packings is essential because they provide a superior seal that directly prevents catastrophic leaks, ensures product purity, and protects the long-term health of your industrial equipment. This choice is not just a material specification; it is a foundational decision for maintaining safe and efficient operations.

The decision to use high-quality PTFE packing moves beyond simply stopping a leak. It is a strategic investment in operational reliability, mitigating the significant financial and safety risks associated with equipment failure, contamination, and unplanned downtime.

The Core Function: Sealing Integrity

In any industrial process involving fluid or gas transfer, the seal is a critical point of failure. A compromised seal can have cascading consequences far beyond a simple drip.

Preventing Hazardous Leaks

High-quality PTFE packings create a robust and resilient barrier. This is the first line of defense in preventing the escape of corrosive, toxic, or high-temperature materials that could endanger personnel and the surrounding environment.

Ensuring Product Purity

For processes in chemical manufacturing or high-purity applications, preventing external contamination is paramount. A superior seal ensures that the process medium remains uncontaminated, protecting the quality and value of the final product.

Protecting Equipment Longevity

A failing packing doesn't just leak externally; it can cause internal damage. Leaks can lead to corrosion of valve stems, pump shafts, and housings, drastically shortening the service life of expensive capital equipment.

Why PTFE Excels in Demanding Conditions

Polytetrafluoroethylene (PTFE) is not just a standard material; its unique molecular properties make it exceptionally suited for the most challenging industrial sealing applications.

Unmatched Chemical Resistance

PTFE is virtually inert to most industrial chemicals and corrosive agents. This allows it to maintain its structural integrity and sealing capability without degrading, even when handling aggressive acids or solvents.

High-Temperature and Abrasion Stability

Industrial processes often involve extreme heat and mechanical stress. PTFE maintains its key properties under these harsh conditions, resisting melting or breaking down where other materials would fail.

Low-Friction Surface

PTFE's famously low coefficient of friction is a major advantage. In applications with moving parts, like valves and pumps, this reduces wear on both the packing and the equipment, leading to lower maintenance requirements and a longer operational lifespan.

Understanding the Trade-offs: The "High-Quality" Imperative

The distinction between standard PTFE and high-quality PTFE packing is critical. The initial cost of a component is often insignificant compared to the potential cost of its failure.

The Hidden Risk of Inferior Materials

Low-cost PTFE packings can suffer from inconsistent density, impurities, or improper manufacturing. These flaws create weak points that are prone to premature failure, completely negating the inherent advantages of the material.

The True Cost of Failure

A cheap packing that fails can trigger a plant shutdown, resulting in massive production losses, expensive emergency repairs, and potential safety incidents. The cost of this downtime can easily exceed the initial savings by several orders of magnitude.

Investing in Uptime and Reliability

Opting for high-quality PTFE from a reputable source is an investment in predictability. It provides a reliable sealing solution that extends service life, optimizes performance, and reduces the overall maintenance burden on your team.

Making the Right Choice for Your Goal

Your specific operational priorities should guide your selection criteria.

- If your primary focus is personnel and environmental safety: Prioritize packings with certified purity and a proven performance record to eliminate the risk of hazardous leaks.

- If your primary focus is maximizing uptime and production efficiency: Invest in durable, low-friction PTFE packings that reduce maintenance cycles and extend the service life of your equipment.

- If your primary focus is product quality and purity: Select PTFE materials specifically rated for your process chemicals and temperatures to prevent any chance of contamination.

Ultimately, selecting high-quality PTFE packing is a strategic investment in the safety, efficiency, and long-term reliability of your entire operation.

Summary Table:

| Key Benefit | Impact |

|---|---|

| Prevents Hazardous Leaks | Protects personnel and environment from toxic/corrosive materials. |

| Ensures Product Purity | Eliminates contamination in chemical and high-purity processes. |

| Protects Equipment | Reduces wear on valves and pumps, extending service life. |

| Maximizes Uptime | Minimizes unplanned downtime and costly emergency maintenance. |

Secure Your Operations with KINTEK's High-Performance PTFE Solutions

Don't let a simple component compromise your entire operation. KINTEK specializes in manufacturing precision PTFE components—including seals, packings, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our commitment to quality ensures your equipment runs safely and efficiently, minimizing downtime and protecting your valuable products.

We offer custom fabrication from prototypes to high-volume orders, tailored to your exact specifications and process conditions.

Contact KINTEK today for a consultation and see how our PTFE expertise can enhance your process reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications