The fundamental reason it's so difficult to glue Teflon (PTFE) is the same reason it makes a great non-stick pan. Its surface is one of the most non-reactive and low-friction materials known to science. Standard adhesives are designed to grip onto a surface either mechanically or chemically, and PTFE's unique molecular structure offers virtually nothing for them to hold.

Gluing Teflon is a challenge because its chemical structure, built on incredibly strong carbon-fluorine bonds, creates an extremely low-energy, non-reactive surface. Adhesives cannot properly "wet" or chemically react with this surface, preventing a strong bond from forming.

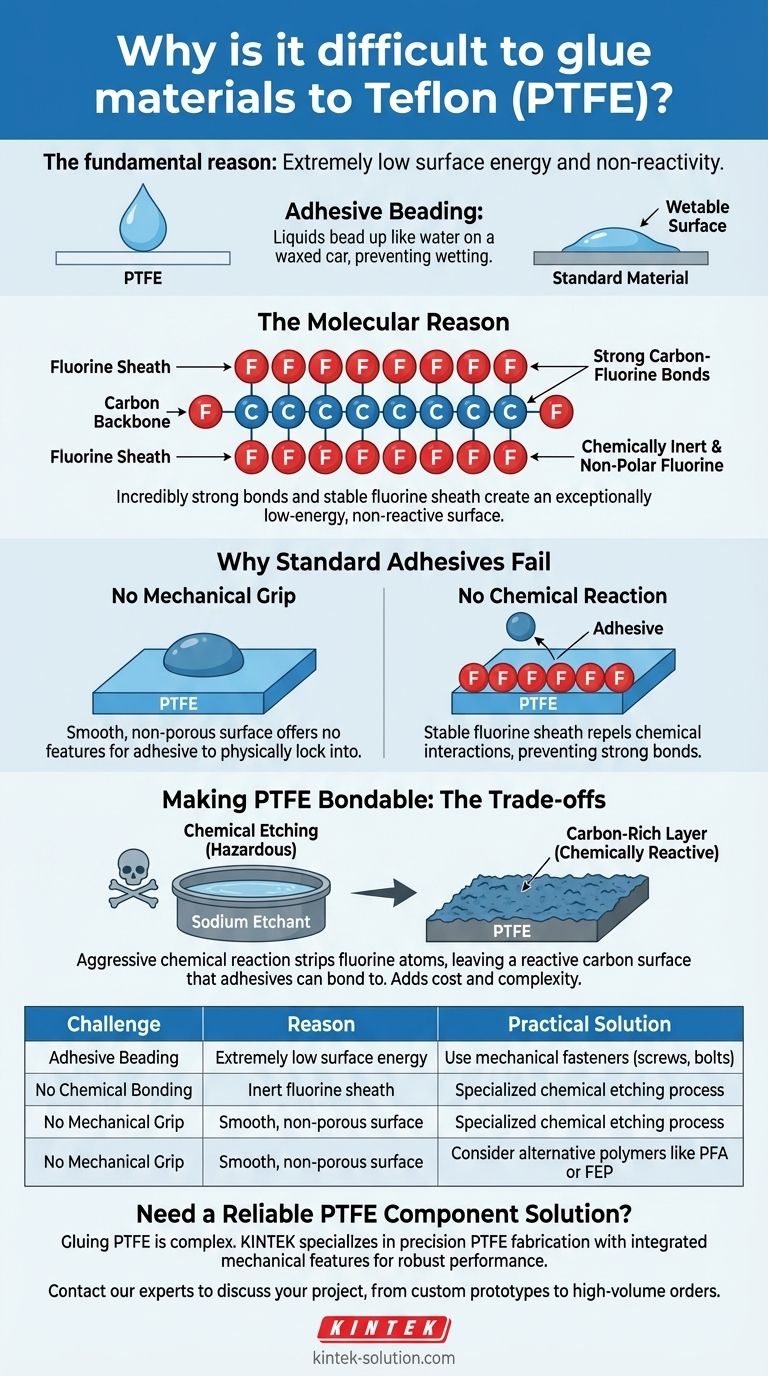

The Molecular Reason for Teflon's "Slipperiness"

To understand why glue fails, we have to look at the material at a molecular level. The properties of Polytetrafluoroethylene (PTFE) are dictated almost entirely by its unique chemical makeup.

The Power of the Carbon-Fluorine Bond

The backbone of the PTFE polymer is a chain of carbon atoms. Each carbon atom is bonded to two fluorine atoms, and the carbon-fluorine bond is one of the strongest single bonds in organic chemistry.

The Protective Fluorine Sheath

These fluorine atoms are larger than the carbon atoms they're attached to. They effectively form a tight, dense, and uniform "sheath" around the carbon backbone. This protective sheath is what the outside world interacts with.

Incredibly Low Surface Energy

This stable fluorine sheath is chemically inert and non-polar, which results in an exceptionally low surface energy. For an adhesive to work, it must spread out and cover, or "wet," the surface. On PTFE, the low surface energy forces liquid adhesives to bead up—much like water on a freshly waxed car—preventing the intimate contact required for adhesion.

Why Standard Adhesives Fail

Adhesives typically work in one of two ways: mechanical interlocking or chemical bonding. PTFE defeats both of these mechanisms with ease.

No Mechanical Grip

Many glues work by seeping into microscopic pores and crevices on a material's surface, hardening, and creating a strong mechanical lock. The surface of PTFE is generally smooth and non-porous, offering no features for the adhesive to physically grip.

No Chemical Reaction

High-strength adhesives like epoxies and cyanoacrylates ("super glue") rely on forming strong chemical bonds with the surface molecules of the material they are applied to. The fluorine sheath on PTFE is so stable and non-reactive that it repels these chemical interactions, leaving the adhesive with nothing to bond to.

Understanding the Trade-offs: Making PTFE Bondable

It is technically possible to glue PTFE, but it is not a simple process. It requires fundamentally and permanently altering the surface of the material.

The Necessity of Chemical Etching

The only reliable method to prepare PTFE for bonding is to use a chemical etching process. This is a hazardous and highly specialized procedure.

How Etching Works

Specialized etchants, typically solutions containing metallic sodium, are used to treat the PTFE surface. This aggressive chemical reaction physically strips fluorine atoms off the polymer backbone, leaving a carbon-rich layer.

The Result: A New, Bondable Surface

This newly exposed layer is no longer "Teflon." It becomes a visually distinct, darker surface that is now chemically reactive and has a higher surface energy. Adhesives can now properly wet this surface and form strong chemical bonds with the exposed carbon.

The Inherent Cost and Complexity

This process is not trivial. The chemicals are dangerous, require specialized handling and disposal, and the process adds significant cost and complexity to any project. This is the critical trade-off: to make PTFE bondable, you must first turn it into a different material.

Making the Right Choice for Your Goal

Before attempting to bond PTFE, it is critical to evaluate if it is the right approach for your application. Your goal should dictate your strategy.

- If you absolutely must bond PTFE: You have no choice but to use a chemical etching process to prepare the surface before applying a specialized industrial adhesive, such as a structural epoxy.

- If your primary focus is simple and reliable assembly: Abandon gluing and opt for mechanical fastening. Using screws, bolts, or rivets is a far more practical and dependable method for securing PTFE components.

- If you are flexible on material choice: Consider alternative fluoropolymers like PFA or FEP, which offer similar properties but may provide slightly better options for certain fabrication methods.

Ultimately, understanding the fundamental non-reactive nature of PTFE is the key to avoiding frustration and choosing the right assembly strategy for your design.

Summary Table:

| Challenge | Reason | Practical Solution |

|---|---|---|

| Adhesive Beading | Extremely low surface energy prevents 'wetting' | Use mechanical fasteners (screws, bolts) |

| No Chemical Bonding | Inert fluorine sheath repels chemical reactions | Specialized chemical etching process |

| No Mechanical Grip | Smooth, non-porous surface offers no grip | Consider alternative polymers like PFA or FEP |

Need a Reliable PTFE Component Solution?

Gluing PTFE is complex, but designing with it doesn't have to be. At KINTEK, we specialize in precision PTFE fabrication for the semiconductor, medical, laboratory, and industrial sectors. We can manufacture your seals, liners, and labware with the exact specifications and assembly methods—like integrated mechanical features—to ensure robust performance without the challenges of adhesion.

Let us handle the complexities of high-performance polymers for you. Contact our experts today to discuss your project, from custom prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability