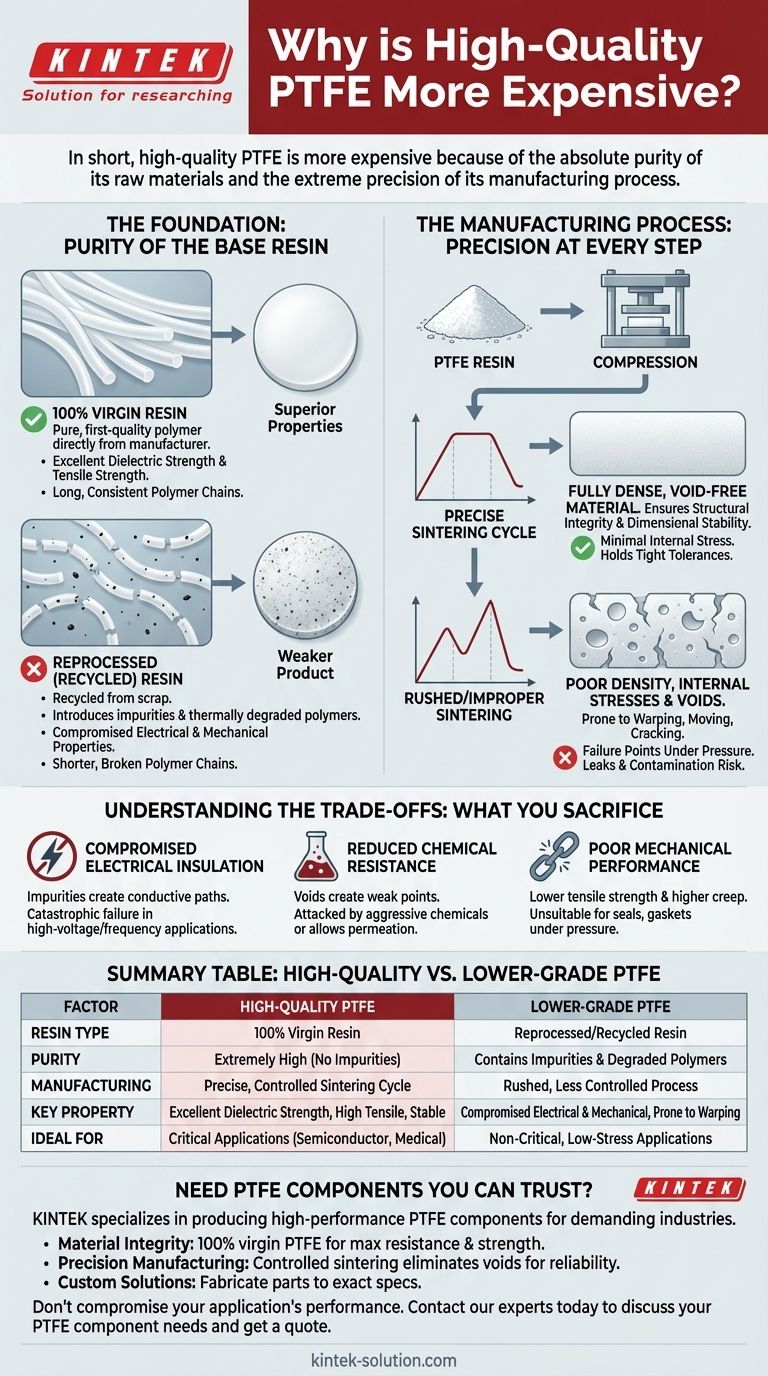

In short, high-quality PTFE is more expensive because of the absolute purity of its raw materials and the extreme precision of its manufacturing process. These two factors—what it's made of and how it's made—are fundamentally different from lower-grade alternatives and are essential for creating a material that meets critical performance standards. The price reflects a deliberate investment in material integrity and reliability.

The higher cost of premium Polytetrafluoroethylene (PTFE) is not just a matter of branding; it is a direct result of using 100% virgin resins and a highly controlled manufacturing process to eliminate the microscopic impurities and structural defects that cause failure in demanding applications.

The Foundation: Purity of the Base Resin

The single greatest cost driver is the quality of the raw PTFE resin. This is the non-negotiable starting point that dictates the final properties of the material.

Virgin vs. Reprocessed (Recycled) Resin

High-performance PTFE is made exclusively from virgin resin. This is pure, first-quality polymer produced directly by the chemical manufacturer.

In contrast, lower-cost PTFE often uses reprocessed or "repro" resin. This is recycled material from scrap, shavings, or rejected parts, which introduces impurities and thermally degraded polymers.

The Impact of Impurities

Even microscopic carbon specks or foreign particles, common in reprocessed resin, can compromise PTFE's properties. These impurities can drastically reduce its dielectric strength, making it unsuitable for electrical insulation.

Polymer Chain Length and Consistency

Virgin resin is characterized by long, consistent polymer chains. This molecular structure is directly responsible for PTFE's superior tensile strength, durability, and resistance to stress cracking. Reprocessed material contains shorter, broken polymer chains, resulting in a mechanically weaker product.

The Manufacturing Process: Precision at Every Step

Transforming pure resin into a stable, usable form requires a manufacturing process that is as much a science as the chemistry itself. This precision is a major cost component.

Sintering: The Critical Heating Process

PTFE is not melted and molded like typical plastics. It is compressed into a shape and then sintered—a carefully controlled heating and cooling cycle that fuses the particles.

An improper sintering cycle, often rushed to save costs, results in a material with poor density, internal stresses, and microscopic voids. Premium PTFE is sintered using precise, time-intensive profiles to ensure full fusion and structural integrity.

Dimensional Stability and Tolerances

High-quality manufacturing produces stock shapes (rods, sheets, tubes) with minimal internal stress. This ensures the material remains dimensionally stable and holds tight tolerances when machined into a final part. Cheaper PTFE is prone to warping, moving, or even cracking after machining as internal stresses are relieved.

Eliminating Voids and Porosity

The goal of a premium manufacturing process is to create a fully dense, void-free material. Microscopic voids, common in low-grade PTFE, become failure points under pressure, in vacuum applications, or when exposed to aggressive chemicals, leading to leaks and contamination.

Understanding the Trade-offs: What You Sacrifice with Lower Quality

Choosing a lower-cost PTFE is not a simple cost-saving measure; it is an engineering compromise that involves sacrificing specific performance characteristics.

Compromised Electrical Insulation

For high-voltage or high-frequency applications, the choice is clear. Impurities in low-grade PTFE create conductive paths, causing catastrophic failure of its insulating properties. The reliability of virgin PTFE is non-negotiable here.

Reduced Chemical Resistance

While all PTFE is chemically resistant, voids and impurities in cheaper material create weak points. These can be attacked by highly aggressive chemicals or allow permeation, where gases pass directly through the material.

Poor Mechanical Performance

Low-grade PTFE exhibits significantly lower tensile strength and is more susceptible to "creep"—the tendency to deform permanently under a sustained load. This makes it unsuitable for seals, gaskets, or structural components that operate under pressure.

Making the Right Choice for Your Application

The distinction between grades of PTFE is about aligning the material's capabilities with the demands of the application.

- If your primary focus is critical electrical insulation: The higher cost of virgin, high-purity PTFE is a mandatory investment in safety and reliability.

- If your primary focus is sealing aggressive chemicals or high-purity media: You must use high-quality, void-free PTFE to prevent system failure, leaks, and contamination.

- If your primary focus is a non-critical, low-stress application like a simple bushing: A well-made mechanical grade or even a reprocessed PTFE might be a viable cost-saving measure.

Ultimately, the choice depends on understanding that with PTFE, you are paying for performance and peace of mind, not just a raw material.

Summary Table:

| Factor | High-Quality PTFE | Lower-Grade PTFE |

|---|---|---|

| Resin Type | 100% Virgin Resin | Reprocessed/Recycled Resin |

| Purity | Extremely High (No Impurities) | Contains Impurities & Degraded Polymers |

| Manufacturing | Precise, Controlled Sintering Cycle | Rushed, Less Controlled Process |

| Key Property | Excellent Dielectric Strength, High Tensile Strength, Dimensional Stability | Compromised Electrical & Mechanical Properties, Prone to Warping |

| Ideal For | Critical Applications (Semiconductor, Medical, High-Purity Labs) | Non-Critical, Low-Stress Applications |

Need PTFE Components You Can Trust?

When failure is not an option, you need PTFE parts manufactured to the highest standards of purity and precision. KINTEK specializes in producing high-performance PTFE components—including seals, liners, and custom labware—for the most demanding industries.

We guarantee:

- Material Integrity: We use only 100% virgin PTFE resins to ensure maximum chemical resistance and dielectric strength.

- Precision Manufacturing: Our controlled sintering and machining processes eliminate voids and internal stresses, delivering superior dimensional stability and reliability.

- Custom Solutions: From prototypes to high-volume production, we fabricate parts to your exact specifications for semiconductor, medical, laboratory, and industrial applications.

Don't compromise your application's performance. Contact our experts today to discuss your PTFE component needs and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are PTFE Lip Seals? High-Performance Sealing for Demanding Rotary Applications

- What is a PTFE lined butterfly valve and what are its main advantages? Superior Control for Corrosive & High-Purity Fluids

- How are PTFE seals applied in the oil and gas industry? Ensure Reliability in Extreme HPHT Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What challenges do manufacturers face when designing PTFE sliding bearings? Navigating Custom Engineering for Structural Safety

- What are the basic types of PTFE Teflon gaskets? Choose the Right Seal for Your Application

- What are the key characteristics of PTFE plugs? Master Performance in Extreme Conditions

- What types of fluids can ePTFE gaskets seal effectively? Ensure Leak-Free Performance with Superior Chemical Resistance