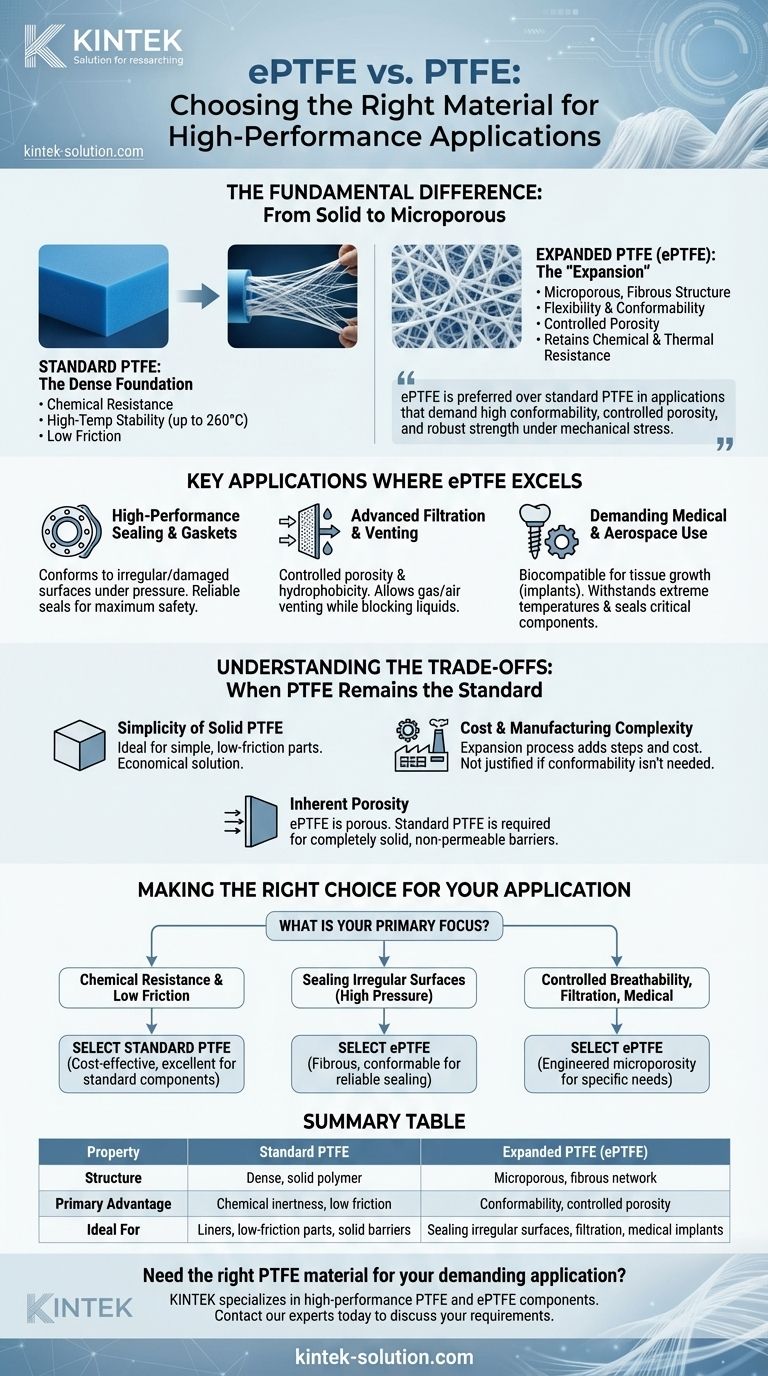

In essence, ePTFE is preferred over standard PTFE in applications that demand high conformability, controlled porosity, and robust strength under mechanical stress. While both materials are chemically identical, the manufacturing process for ePTFE creates a unique microporous, fibrous structure. This structure gives it enhanced physical properties that solid PTFE simply does not possess.

The choice between PTFE and ePTFE is not a matter of one being universally superior. The decision hinges entirely on the material's physical structure: select dense, solid PTFE for its bulk inertness and low friction, but choose fibrous, microporous ePTFE when you need to seal irregular surfaces, filter media, or integrate with biological tissue.

The Fundamental Difference: From Solid to Microporous

The unique advantages of ePTFE stem directly from a physical transformation of standard PTFE. Understanding this process is key to selecting the right material.

Standard PTFE: The Dense Foundation

Polytetrafluoroethylene (PTFE) in its standard form is a dense, solid polymer.

Its reputation is built on an exceptional combination of properties: outstanding chemical resistance, high-temperature stability up to 260°C, and one of the lowest coefficients of friction of any solid.

This makes it the default choice for applications like non-stick coatings, chemical-resistant liners, and simple valve components.

The "Expansion" of ePTFE

Expanded Polytetrafluoroethylene (ePTFE) begins as standard PTFE but undergoes a mechanical stretching process.

This expansion pulls the material apart, creating a complex network of strong, interconnected fibers and microscopic pores. This is what is meant by its multi-directional fibrous structure.

What This Structural Change Unlocks

This transformation from a solid to a microporous fibrous web is the source of all of ePTFE's distinct advantages.

The new structure provides flexibility, conformability, and controlled porosity while retaining the original chemical and thermal resistance of PTFE.

Key Applications Where ePTFE Excels

The unique physical properties of ePTFE make it the superior choice for specific, high-stakes engineering challenges.

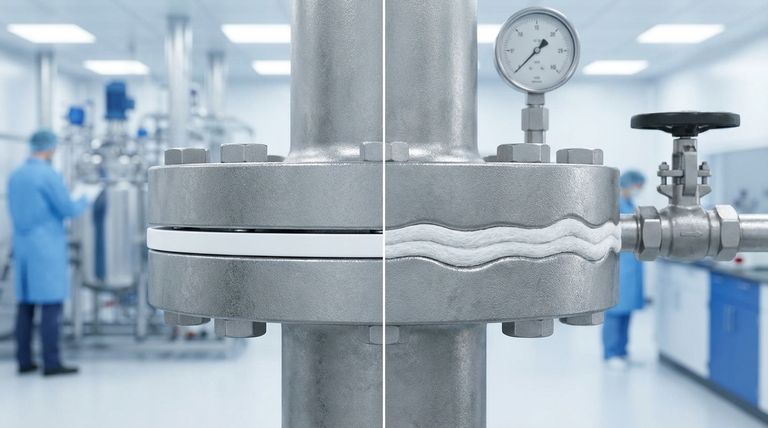

High-Performance Sealing and Gaskets

The fibrous nature of ePTFE allows it to compress and conform to irregular or damaged surfaces under high pressure, creating a highly reliable seal where solid PTFE might fail.

This is why it is specified for maximum safety demands, such as sealing flanges for oxygen-carrying tubes or in harsh chemical processing environments.

Advanced Filtration and Venting

ePTFE's controlled porosity and hydrophobic (water-repelling) nature make it an ideal membrane for filtration.

It allows gases and air to pass through for venting while effectively blocking liquids and contaminants. This performance is critical in sensitive electronics, automotive components, and industrial filtration systems.

Demanding Medical and Aerospace Use

In the medical field, ePTFE is highly biocompatible. Its porous structure allows for natural cell and tissue growth, making it ideal for implants like synthetic arteries, hernia patches, and surgical membranes.

In aerospace, its ability to withstand extreme temperatures combined with its superior sealing capabilities makes it invaluable for gaskets, seals, and insulation in critical aircraft components.

Understanding the Trade-offs: When PTFE Remains the Standard

Despite the advanced capabilities of ePTFE, it is not always the right choice. The expansion process introduces trade-offs in complexity and cost.

The Simplicity of Solid PTFE

For many applications, the advanced features of ePTFE are unnecessary.

When the primary need is for a solid, low-friction, or chemically inert machined part like a ball valve seat or an electrical insulator, standard PTFE provides excellent performance reliably and economically.

Cost and Manufacturing Complexity

The process of creating ePTFE adds manufacturing steps, which typically results in a higher material cost compared to standard PTFE resins or stock shapes.

If the application does not explicitly require conformability or porosity, the added expense of ePTFE may not be justified.

Inherent Porosity

The defining feature of ePTFE is also its key limitation. If your application requires a completely solid, non-permeable barrier with zero porosity, then standard PTFE is the only option.

Making the Right Choice for Your Application

Your material selection should be guided by the specific mechanical, environmental, and cost demands of your design.

- If your primary focus is chemical resistance and low friction in a standard component: Standard PTFE offers excellent performance and is often the most cost-effective solution.

- If your primary focus is sealing irregular surfaces under high pressure: The fibrous, conformable structure of ePTFE provides a more reliable and durable seal.

- If your primary focus is controlled breathability, filtration, or medical implantation: The engineered microporosity of ePTFE makes it the superior and often only viable choice.

Understanding the structural distinction between dense PTFE and fibrous ePTFE empowers you to select the precise material your application demands.

Summary Table:

| Property | Standard PTFE | Expanded PTFE (ePTFE) |

|---|---|---|

| Structure | Dense, solid polymer | Microporous, fibrous network |

| Primary Advantage | Chemical inertness, low friction | Conformability, controlled porosity |

| Ideal For | Liners, low-friction parts, solid barriers | Sealing irregular surfaces, filtration, medical implants |

Need the right PTFE material for your demanding application?

KINTEK specializes in manufacturing high-performance PTFE and ePTFE components, including custom seals, liners, and labware. Whether your project is in the semiconductor, medical, laboratory, or industrial sector, our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a component engineered for success.

Contact our experts today to discuss your specific requirements and discover how our PTFE solutions can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability