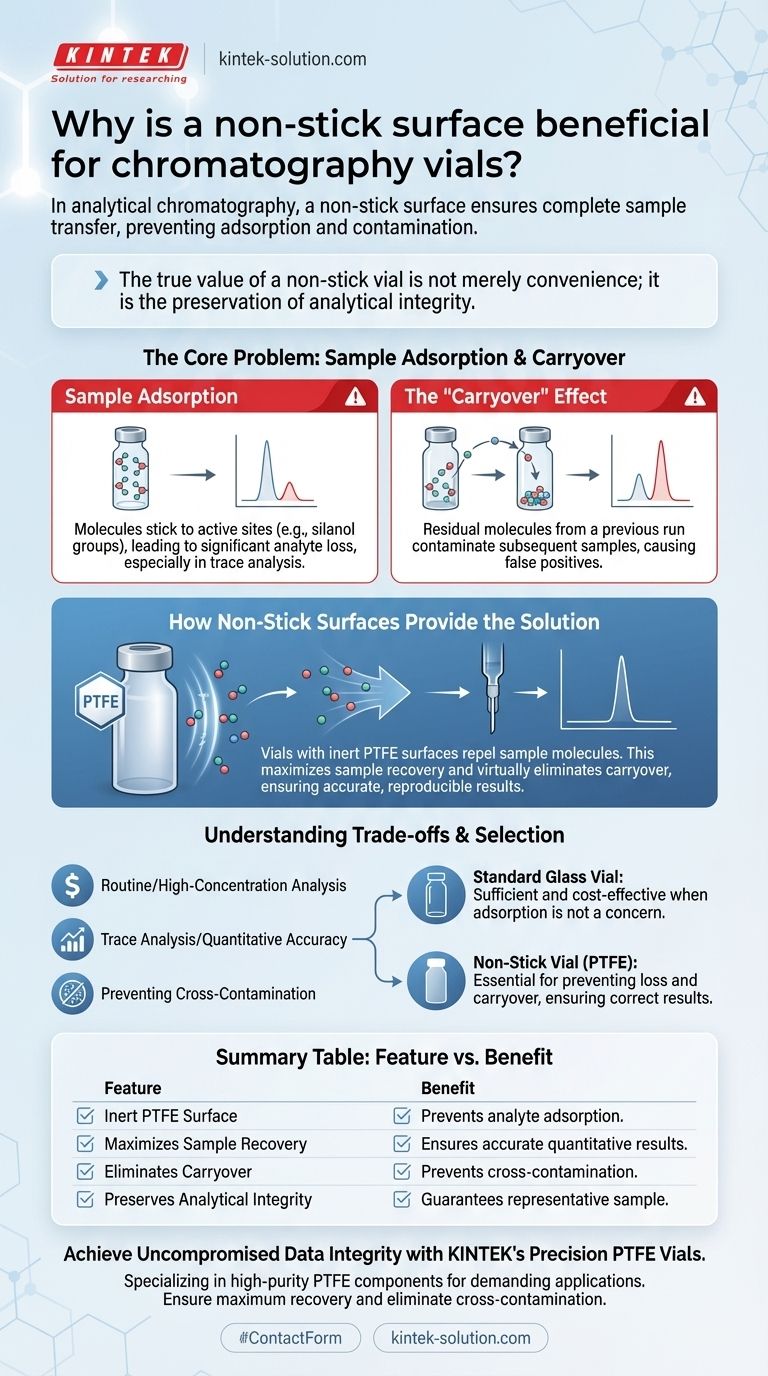

In analytical chromatography, a non-stick vial surface is beneficial because it ensures the complete and accurate transfer of your sample from the vial to the instrument. By preventing molecules from sticking to the vial's interior, it maximizes sample recovery and eliminates the risk of residual material contaminating subsequent analyses.

The true value of a non-stick vial is not merely convenience; it is the preservation of analytical integrity. It guarantees that the sample you inject is an unaltered, complete representation of the sample you prepared, which is the foundation of all reliable data.

The Core Problem: Sample Adsorption in Vials

What is Sample Adsorption?

Standard glass and some plastic vials have chemically active surfaces. These surfaces contain sites, such as free silanol groups in glass, that can attract and bind certain types of molecules from your sample solution. This phenomenon is known as adsorption.

The Impact on Low-Concentration Samples

When analyzing samples at very low concentrations (trace analysis), even a minuscule amount of analyte loss due to adsorption can be significant. This loss leads to inaccurate and lower-than-expected quantitative results because not all of the analyte makes it into the instrument for measurement.

The "Carryover" Effect

Adsorption also creates the risk of carryover. Molecules that stick to the vial wall during one analysis can detach and mix with the sample in a subsequent run. This cross-contamination can lead to false positives or inaccurately high readings in later analyses.

How Non-Stick Surfaces Provide the Solution

The Role of Inert Materials

Vials with non-stick properties are typically made from or lined with highly inert materials like Polytetrafluoroethylene (PTFE). The low surface energy and chemical inertness of PTFE prevent samples from adhering to the vial walls.

Maximizing Sample Recovery

By creating a surface that repels sample molecules, these vials ensure that the entire prepared sample is available for the autosampler to draw from. This leads to maximum sample recovery, which is critical for achieving accurate and precise quantitative results.

Eliminating Cross-Contamination

Because no residue is left behind, the risk of carryover between injections is virtually eliminated. Each analysis is clean and independent, which enhances the reliability and reproducibility of your entire analytical sequence.

Understanding the Trade-offs

When They Aren't Necessary

For routine analyses of high-concentration samples or with analytes that are not prone to adsorption, a standard, high-quality glass vial is often sufficient. Using a specialized non-stick vial in these cases may offer no significant analytical benefit and would be less cost-effective.

Material and Cost Considerations

Vials with non-stick coatings or those made from advanced polymers are more expensive than standard glass vials. You must weigh the added cost against the potential for inaccurate data. Always ensure the vial material is compatible with your sample and solvents to prevent leaching of contaminants from the vial itself.

Selecting the Right Vial for Your Analysis

Choosing the correct vial is a foundational step in generating reliable chromatographic data. Use your analytical goal to guide your decision.

- If your primary focus is quantitative accuracy with trace analytes: A non-stick vial is essential to prevent sample loss and ensure your results are correct.

- If your primary focus is preventing cross-contamination: Non-stick vials provide the best defense against carryover, especially when running many different samples sequentially.

- If your primary focus is routine analysis of non-sticky compounds: A high-quality, standard glass vial is likely the most practical and economical choice.

Ultimately, selecting the proper vial transforms it from a simple container into a tool for ensuring data integrity.

Summary Table:

| Feature | Benefit for Chromatography |

|---|---|

| Inert PTFE Surface | Prevents analyte adsorption to vial walls |

| Maximizes Sample Recovery | Ensures accurate quantitative results, especially for trace analysis |

| Eliminates Carryover | Prevents cross-contamination between sequential samples |

| Preserves Analytical Integrity | Guarantees the sample injected is a complete representation of the prepared sample |

Achieve Uncompromised Data Integrity with KINTEK's Precision PTFE Vials

Are sample loss and carryover compromising your chromatographic results? KINTEK specializes in manufacturing high-purity PTFE components, including non-stick chromatography vials, designed specifically for the demanding needs of analytical laboratories.

Our vials ensure maximum sample recovery and eliminate cross-contamination, providing the foundation for reliable data in semiconductor, medical, and laboratory applications. We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact us today to discuss how our precision PTFE vials can enhance your analytical workflow and protect the integrity of your most critical samples.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How are PTFE stirrers and shafts typically constructed for industrial use? Choose the Right Method for Your Process

- What are the key properties of PTFE that make it suitable for chromatography septums? Ensure Sample Integrity and Reliable Results

- What is the significance of thickness in PTFE-coated septums? Maximize Durability and Analytical Reliability

- How do Teflon membranes improve the functionality of gas chromatography? Achieve Purer, More Accurate Results

- How do PTFE/silicone septa reduce sample carryover in HPLC analysis? Achieve Accurate, Contamination-Free Results

- How are PTFE syringe filters modified for hydrophilic applications? Achieve Easy Filtration of Aqueous Solutions

- What are common industrial applications of PTFE filters? Master Critical Filtration in Demanding Industries

- What are the chemical resistance properties of PTFE labware? The Ultimate Guide to Inert Labware