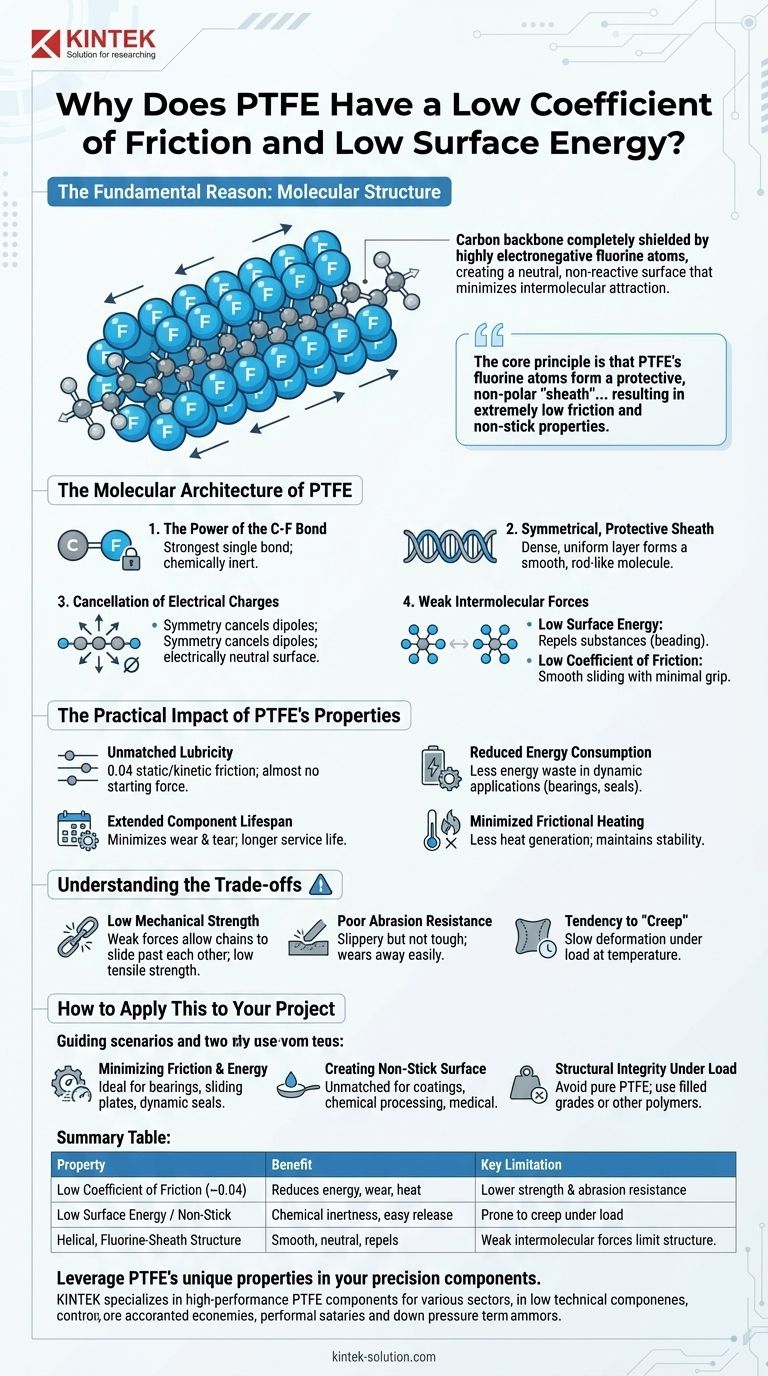

The fundamental reason for PTFE's uniquely low coefficient of friction and low surface energy lies in its molecular structure. The polymer consists of a carbon backbone completely shielded by a symmetrical arrangement of highly electronegative fluorine atoms, creating an electrically neutral and non-reactive surface that minimizes intermolecular attraction.

The core principle is that PTFE's fluorine atoms form a protective, non-polar "sheath" around the polymer chain. This sheath repels nearly everything, resulting in extremely low friction and non-stick properties, but this same weak intermolecular attraction also leads to lower mechanical strength.

The Molecular Architecture of PTFE

The remarkable properties of Polytetrafluoroethylene (PTFE) are not magic; they are a direct result of its specific chemical makeup and physical structure. Understanding this foundation is key to using the material effectively.

The Power of the Carbon-Fluorine Bond

The bond between carbon and fluorine is one of the strongest known single bonds in organic chemistry. Fluorine is the most electronegative element, meaning it holds its electrons very tightly. This creates an incredibly stable and chemically inert molecule.

A Symmetrical, Protective Sheath

In the PTFE polymer, the long carbon chain is surrounded by a dense, uniform layer of these fluorine atoms. This arrangement forms a helical, rod-like molecule that is exceptionally smooth and regular on a molecular level.

Cancellation of Electrical Charges

Because the fluorine atoms are arranged so symmetrically, the individual electrical dipoles of the C-F bonds cancel each other out. This leaves the overall molecule in a neutral electronic state, with no significant positive or negative charges exposed on its surface.

Weak Intermolecular Forces

The consequence of this electrical neutrality is that the attractive forces (known as van der Waals forces) between PTFE molecules and other surfaces are exceptionally weak. This is the direct cause of its famous properties:

- Low Surface Energy: Other substances are not attracted to the PTFE surface, which is why they bead up and do not "wet" or stick to it.

- Low Coefficient of Friction: Molecules slide past the smooth, non-polar PTFE surface with minimal resistance because there is almost no intermolecular "grip."

The Practical Impact of PTFE's Properties

This unique molecular behavior translates directly into significant real-world advantages in mechanical and industrial applications.

Unmatched Lubricity

PTFE has an exceptionally low coefficient of friction, with static and kinetic values around 0.04. This is significantly lower than even lubricated steel and means it takes almost no extra force to start an object moving as it does to keep it moving.

Reduced Energy Consumption

In dynamic applications like bearings, seals, and impellers, low friction means less energy is wasted overcoming resistance. This leads to improved operational efficiency and tangible power savings, especially in high-speed machinery.

Extended Component Lifespan

By minimizing friction, PTFE drastically reduces wear and tear on moving parts. Using PTFE washers, O-rings, or coatings can significantly extend the service life of components in automotive, aerospace, and hydraulic systems.

Minimized Frictional Heating

A critical benefit in dynamic systems is the reduction of heat generation. Less friction means less thermal buildup, which helps maintain the stability and performance of seals and other components under stress.

Understanding the Trade-offs

The same molecular properties that provide PTFE's incredible benefits also create inherent weaknesses. The trusted advisor must acknowledge these limitations.

Low Mechanical Strength

The weak forces between PTFE polymer chains not only allow other materials to slide past easily, but they also allow the PTFE chains to slide past each other. This results in relatively low tensile strength and hardness compared to other engineering plastics.

Poor Abrasion Resistance

While PTFE is incredibly slippery, it is not particularly tough. Abrasive materials can wear it away more easily than harder plastics because the polymer chains are not strongly bound to one another.

Tendency to "Creep"

Under a sustained load, especially at elevated temperatures, PTFE can slowly deform or "creep." This is another consequence of the polymer chains being able to slide past each other over time. For this reason, PTFE is often reinforced with fillers like glass, carbon, or bronze for structural applications.

How to Apply This to Your Project

Choosing the right material requires understanding both its strengths and its limitations. Your decision should be guided by your primary engineering goal.

- If your primary focus is minimizing friction and energy loss: PTFE is an ideal choice for bearings, sliding plates, and dynamic seals in machinery where efficiency is the top priority.

- If your primary focus is creating a non-stick, chemically inert surface: PTFE coatings are unmatched for applications in cookware, chemical processing, and medical devices.

- If your primary focus is structural integrity under high load: Pure PTFE should be avoided; instead, consider a filled or reinforced grade of PTFE or an entirely different polymer.

By understanding the molecular principles, you can expertly leverage PTFE's strengths while strategically mitigating its inherent weaknesses.

Summary Table:

| Property | Benefit | Key Limitation |

|---|---|---|

| Low Coefficient of Friction (~0.04) | Reduces energy consumption, minimizes wear, and prevents frictional heating. | Lower mechanical strength and abrasion resistance. |

| Low Surface Energy / Non-Stick | Excellent chemical inertness and easy-release properties for clean processing. | Can be prone to creep under sustained load. |

| Helical, Fluorine-Sheath Structure | Provides a smooth, electrically neutral surface that repels other materials. | Weak intermolecular forces limit structural applications in pure form. |

Leverage PTFE's unique properties in your precision components.

At KINTEK, we specialize in manufacturing high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication ensures you get the perfect balance of PTFE's low friction and chemical resistance with the mechanical integrity your application demands, from prototypes to high-volume orders.

Ready to enhance your project's efficiency and lifespan? Contact our experts today to discuss your specific requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries