In chromatography, the integrity of your results depends on controlling every variable, and the vial septum is a critical control point. PTFE/silicone septa are considered essential because their dual-layer construction provides an unmatched combination of chemical inertness from the Polytetrafluoroethylene (PTFE) layer and the reliable, resealable elasticity from the silicone layer. This design ensures sample purity while maintaining a perfect, leak-free seal for the pressurized analytical system.

The choice of a septum is not simply about sealing a vial; it's about creating an inert barrier that protects the sample from contamination while ensuring the analytical system remains perfectly stable. PTFE/silicone septa solve this by combining the distinct strengths of two materials into one high-performance component.

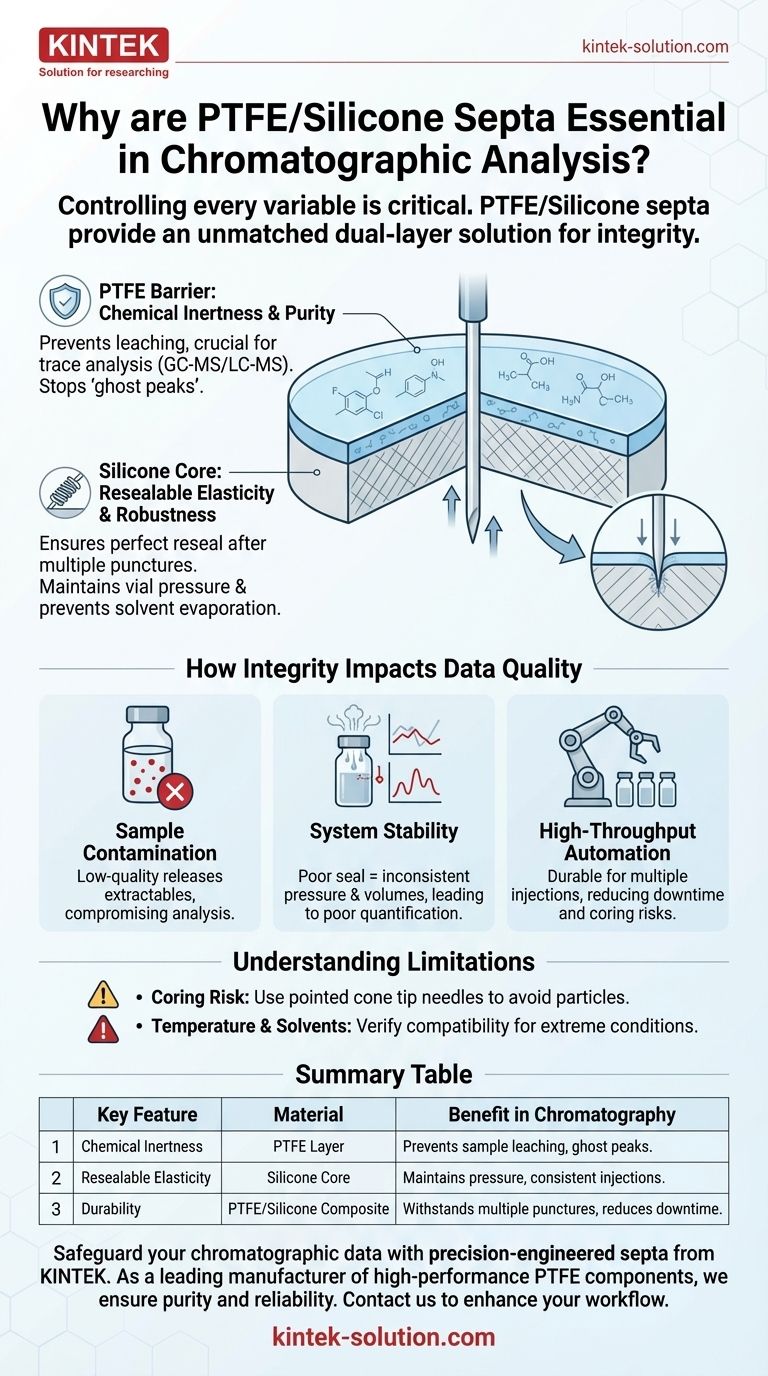

The Anatomy of a High-Performance Septum

To understand why this specific combination is so critical, we must look at the distinct role each material plays. The design solves two separate problems that are both crucial to accurate analysis.

The PTFE Barrier: Your First Line of Defense

The thin layer of PTFE is the only part of the septum that ever comes into contact with your sample.

PTFE is one of the most chemically non-reactive materials available. This inertness prevents the septum from altering the chemical composition of your sample, a phenomenon known as leaching.

This is especially critical in trace analysis (like GC-MS or LC-MS), where even minuscule contamination from the septum could appear as a "ghost peak" or mask the actual components you are trying to measure.

The Silicone Core: Ensuring a Perfect Reseal

Beneath the PTFE barrier lies a much thicker layer of high-purity silicone.

Silicone provides the physical robustness and elasticity. When the autosampler needle pierces the septum, the silicone creates a tight seal around it.

More importantly, after the needle is withdrawn, the silicone's "memory" allows it to reseal the puncture point almost perfectly. This prevents solvent evaporation and maintains consistent pressure within the vial, which is vital for reproducible results.

How Septum Integrity Directly Impacts Data Quality

A failure at the septum level doesn't just cause a minor inconvenience; it can invalidate an entire batch of results. The right septum mitigates these fundamental risks.

Preventing Sample Contamination

A low-quality septum can release extractables into the solvent, introducing contaminants that compromise the analysis. PTFE/silicone septa are designed and manufactured to minimize this risk, ensuring the peaks you see on your chromatogram come from your sample and nothing else.

Maintaining System Stability

In Gas Chromatography (GC), consistent vial pressure is essential for reproducible injection volumes. A septum that fails to reseal creates a leak, leading to inconsistent retention times and poor quantification.

In liquid chromatography (HPLC/UPLC), a poor seal allows solvent to evaporate. This slowly concentrates the sample in the vial, artificially inflating the calculated concentration and destroying the accuracy of your results.

Enabling High-Throughput and Automation

Modern laboratories rely on autosamplers that process hundreds of samples. PTFE/silicone septa are robust enough to withstand multiple injections without significant degradation or "coring" (shedding particles into the vial).

This durability reduces the frequency of septum replacement, minimizes instrument downtime, and enhances the cost-effectiveness of automated workflows.

Understanding the Trade-offs and Limitations

While PTFE/silicone septa are the gold standard, they are not infallible. Awareness of their limitations is key to proper use.

The Risk of Coring

Using the wrong needle type, particularly a blunt or beveled tip instead of a pointed cone tip, can tear the septum. This action can push small particles of the septum material into your sample, a problem known as coring. These particles can block the needle or column.

Temperature Constraints

While robust, silicone has upper-temperature limits. For very high-temperature GC inlet applications, you must select a septum specifically rated for that temperature range to prevent degradation and system contamination.

Solvent Compatibility

Although the PTFE layer is extremely inert, aggressive solvents can, over time or after multiple punctures, potentially compromise the barrier and interact with the underlying silicone. Always confirm compatibility for long-term storage or with unusual solvent systems.

Making the Right Choice for Your Analysis

Selecting the appropriate septum is an active step in ensuring data quality. Your analytical goal should guide your choice.

- If your primary focus is trace analysis (GC-MS, LC-MS/MS): Prioritize septa with the highest purity ratings to eliminate any risk of ghost peaks from leaching.

- If your primary focus is high-throughput screening: Select septa specifically rated for durability and a high number of punctures to guarantee autosampler reliability.

- If your primary focus is regulatory compliance (e.g., pharmaceuticals): Use septa specified by validated methods to ensure the leak-free seals required for precise and legally defensible quantification.

Ultimately, choosing a high-quality PTFE/silicone septum is a critical decision that directly safeguards the integrity and reliability of your final analytical data.

Summary Table:

| Key Feature | Material | Benefit in Chromatography |

|---|---|---|

| Chemical Inertness | PTFE Layer | Prevents sample leaching and ghost peaks in trace analysis |

| Resealable Elasticity | Silicone Core | Maintains vial pressure, ensures consistent injection volumes |

| Durability | PTFE/Silicone Composite | Withstands multiple autosampler punctures, reduces downtime |

Safeguard your chromatographic data with precision-engineered septa from KINTEK.

As a leading manufacturer of high-performance PTFE components for the semiconductor, medical, laboratory, and industrial sectors, we understand the critical need for purity and reliability in analytical applications. Our PTFE/silicone septa are manufactured with exacting standards to ensure they deliver unmatched chemical inertness and resealable performance, protecting your samples and your results.

Whether you require standard components or custom-fabricated solutions—from prototypes to high-volume orders—KINTEK prioritizes precision production to meet your specific needs.

Contact us today to discuss how our septa can enhance the integrity and efficiency of your analytical workflow.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

People Also Ask

- What are the key properties of PTFE that make it suitable for laboratory use? Unmatched Chemical & Thermal Resistance

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications

- What are the main advantages of PTFE as a material for laboratory bottles? Superior Chemical & Thermal Resistance

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- What are PTFE silicone septas and their role in the pharmaceutical industry? Ensure Sample Integrity and Accurate Analysis

- What are the key applications of the PTFE bottle? Ensure Chemical Safety and Sample Purity

- What are the main benefits of PTFE filters? Achieve Unmatched Chemical Resistance and Purity

- What are the reusability and durability characteristics of PTFE-lined bottle caps? Engineered for Repeated, Reliable Use