The exceptional chemical resistance of PTFE valves stems directly from the molecular structure of the Polytetrafluoroethylene polymer itself. The incredibly strong, stable bonds between carbon and fluorine atoms create a non-reactive material that is virtually impervious to attack from almost all common industrial chemicals, acids, and bases.

At its core, PTFE's chemical inertness is not an added feature but a fundamental property of its molecular architecture. This makes it a default choice for applications where material integrity and fluid purity are non-negotiable in aggressive chemical environments.

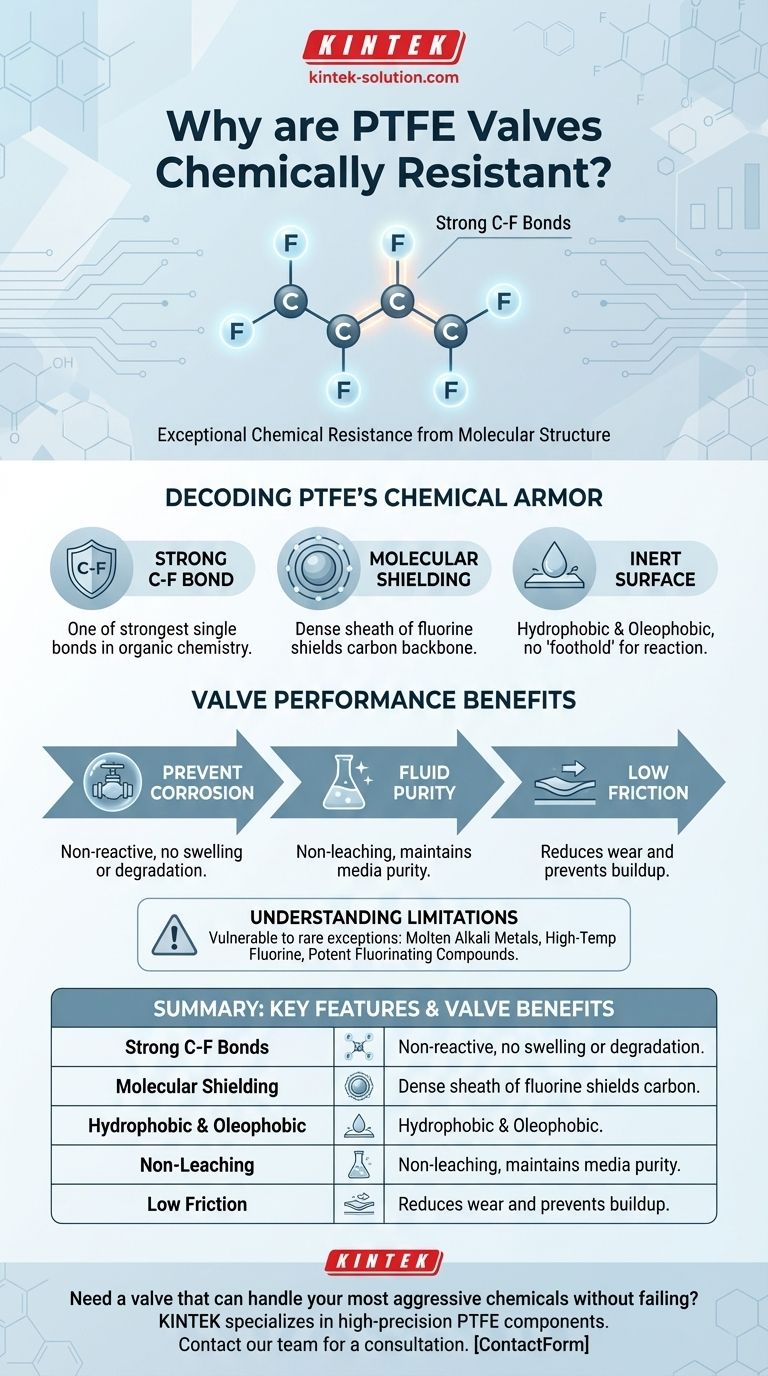

Decoding PTFE's Chemical Armor

The reason PTFE can withstand such a broad spectrum of chemicals is rooted in the unique characteristics of its chemical bonds. This isn't a surface treatment; it's an inherent quality of the material.

The Power of the Carbon-Fluorine Bond

PTFE consists of a long chain of carbon atoms, where each carbon is bonded to two fluorine atoms. The carbon-fluorine (C-F) bond is one of the strongest single bonds in organic chemistry.

These fluorine atoms are also larger than hydrogen atoms found in other polymers, creating a dense, helical sheath of fluorine that effectively shields the vulnerable carbon backbone from any potential chemical attack.

A Chemically Inert Surface

This stable, shielded molecular structure leaves no "foothold" for other chemicals to initiate a reaction. As a result, PTFE is hydrophobic (repels water), oleophobic (repels oil), and does not dissolve in any known solvent at room temperature.

The material simply does not interact with substances like strong acids, alkalis, oxidants such as concentrated sulfuric acid, and halogens like chlorine gas.

What This Means for Valve Performance

This molecular stability translates directly into superior, reliable performance when PTFE is used for valve components like liners, seats, seals, or diaphragms.

Preventing Corrosion and Degradation

Because PTFE is so non-reactive, it will not swell, soften, or degrade when exposed to corrosive fluids. This ensures the valve maintains its dimensional stability and sealing capability over a long service life.

This inertness also protects the purity of the process media. The valve components will not leach materials or contaminants into the fluid flowing through them, which is critical in pharmaceutical, food, and semiconductor applications.

Enhancing Durability with Low Friction

PTFE has an extremely low coefficient of friction, one of the lowest of any solid material. While not a chemical property, this "slipperiness" prevents media from sticking to valve surfaces, reducing wear and the potential for buildup that could compromise the valve's operation.

Understanding the Limitations

While its chemical resistance is nearly universal, it is crucial to understand that no material is completely indestructible. PTFE has a few, very specific vulnerabilities.

The Rare Exceptions

PTFE's chemical resistance is only compromised by a handful of the most aggressive and exotic substances known. These are typically not encountered in most industrial processes but are important to be aware of.

The primary exceptions include molten or dissolved alkali metals (like sodium), high-temperature gaseous fluorine, and potent fluorinating compounds like chlorine trifluoride and oxygen difluoride.

Mechanical vs. Chemical Strength

It is important to distinguish between chemical resistance and mechanical strength. Pure PTFE is a relatively soft material. For this reason, it is often used as a liner or for sealing components within a valve that has a more robust metal body, combining the structural integrity of metal with the chemical inertness of PTFE.

Making the Right Choice for Your Application

Selecting a valve material requires matching its properties to your specific operational demands.

- If your primary focus is handling a wide range of aggressive chemicals: PTFE is an almost universal first choice due to its near-total inertness to common acids, bases, and solvents.

- If your primary focus is process purity: PTFE's non-reactive and non-leaching nature ensures it will not contaminate the fluid, making it ideal for high-purity applications.

- If your primary focus is a rare, extreme environment with molten alkali metals or high-temperature fluorine: You must look beyond standard PTFE and consult specialized material guides for these highly aggressive conditions.

Ultimately, understanding the molecular strength of PTFE empowers you to specify it confidently for the most demanding chemical environments.

Summary Table:

| Key Feature | Benefit for Valve Performance |

|---|---|

| Strong C-F Bonds | Creates a non-reactive, inert surface that resists chemical attack. |

| Molecular Shielding | Dense fluorine sheath protects the carbon backbone from degradation. |

| Hydrophobic & Oleophobic | Repels water and oil, preventing interaction with process media. |

| Non-Leaching | Maintains fluid purity, critical for semiconductor and pharmaceutical uses. |

| Low Friction | Prevents media buildup and reduces wear on seals and seats. |

Need a valve that can handle your most aggressive chemicals without failing?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your valves and systems deliver unmatched chemical resistance and process purity.

We provide custom fabrication from prototypes to high-volume orders, tailoring solutions to your exact specifications. Let's discuss how our PTFE expertise can solve your chemical handling challenges. Contact our team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance