The exceptional high-temperature performance of PTFE O-rings stems directly from the molecular structure of Polytetrafluoroethylene. The incredibly strong and stable bonds between carbon and fluorine atoms require significant thermal energy to break, giving the material a very high melting point and allowing it to maintain its essential properties in extreme heat.

While PTFE's high melting point is a key factor, its true value in high-temperature applications lies in its ability to retain a full suite of desirable properties—including chemical inertness, dimensional stability, and low friction—when other materials would degrade and fail.

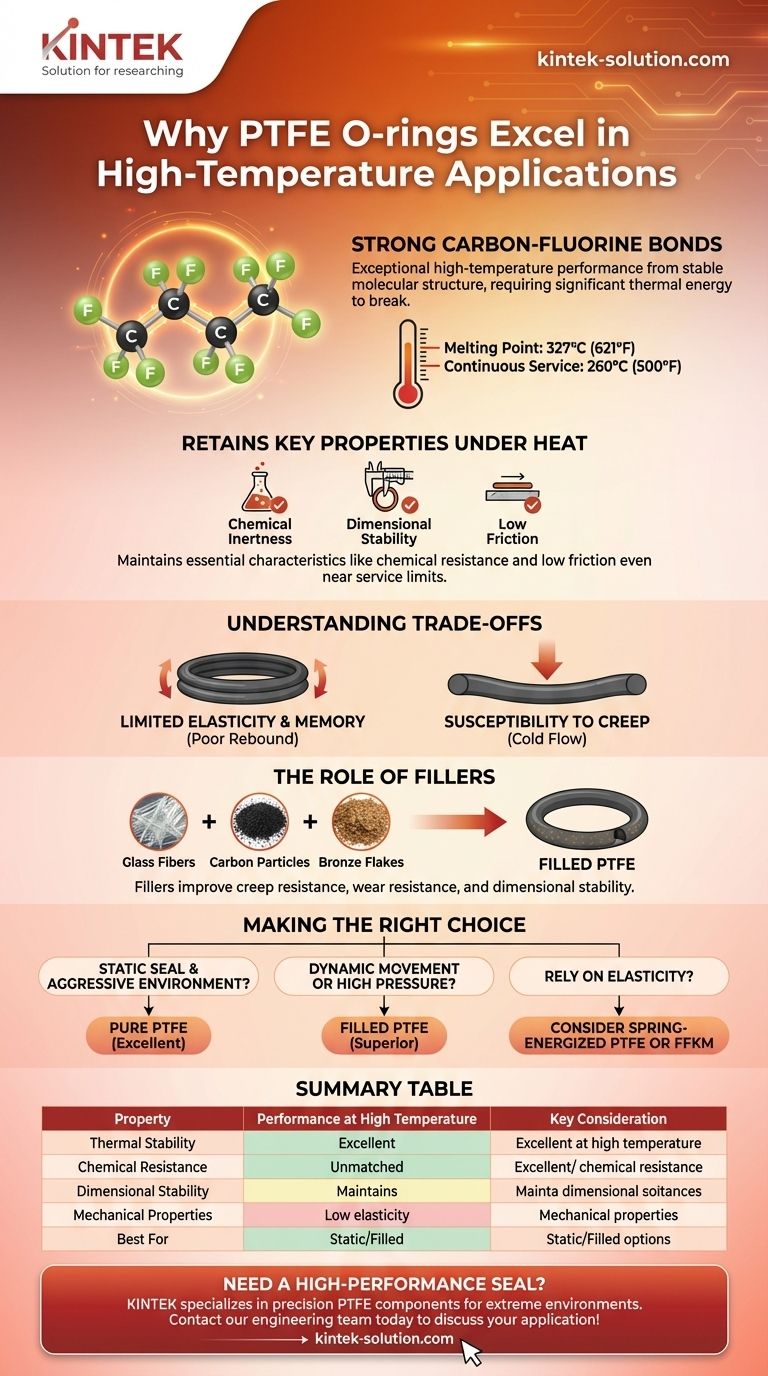

The Science Behind PTFE's Thermal Stability

Understanding why PTFE excels requires looking beyond just a single temperature rating. Its performance is a result of its fundamental chemistry and physical structure.

The Carbon-Fluorine Bond

The backbone of the PTFE polymer is a chain of carbon atoms, each completely shielded by a sheath of fluorine atoms. The carbon-fluorine bond is one of the strongest single bonds in organic chemistry.

This powerful bond structure is what gives PTFE its signature thermal stability and remarkable resistance to chemical attack.

High Melting Point vs. Service Temperature

PTFE has a very high melting point of approximately 327°C (621°F). This is the temperature at which the material physically transitions from a solid to a liquid.

However, its practical continuous service temperature is generally considered to be around 260°C (500°F). Above this temperature, the material begins to soften and its mechanical properties may decline, even though it has not yet melted.

Retaining Key Properties Under Heat

Unlike many materials that become brittle or lose their integrity, PTFE maintains its most valuable characteristics at elevated temperatures.

Even near its service limit, it retains its exceptional chemical resistance, dimensional stability, and low-friction surface. This predictability makes it a reliable choice for demanding engineering environments.

Understanding the Trade-offs of PTFE Seals

No material is perfect. While PTFE offers elite thermal and chemical performance, its mechanical properties present specific design challenges that must be considered.

Limited Elasticity and "Memory"

Pure PTFE is a relatively rigid plastic, not an elastomer like rubber. It lacks the "springiness" or elastic memory of materials like FKM (Viton®) or silicone.

Once compressed, a pure PTFE O-ring does not rebound to its original shape effectively. This can make achieving and maintaining a seal more challenging, especially in applications with pressure or temperature cycling.

Susceptibility to Creep (Cold Flow)

Under a constant compressive load, especially when warm, PTFE is susceptible to creep, also known as cold flow. This is a slow, permanent deformation of the material over time.

This can lead to a loss of sealing pressure and potential leaks if the hardware design does not account for it.

The Role of Fillers

To counteract the mechanical weaknesses of pure PTFE, manufacturers often create "filled PTFE" compounds. Materials like glass, carbon, bronze, or graphite are added to the polymer.

These fillers significantly improve creep resistance, increase wear resistance, and enhance dimensional stability, making filled PTFE grades superior for dynamic or high-pressure applications.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the material's profile to your specific operational demands.

- If your primary focus is a static seal in a high-temperature and chemically aggressive environment: Pure PTFE is an excellent choice due to its unmatched chemical inertness and thermal stability.

- If your application involves dynamic movement or high pressure at elevated temperatures: A filled PTFE grade is almost always a better choice to manage wear and prevent failure from creep.

- If your design relies on the seal's elasticity to maintain force: You must account for PTFE's low rebound and consider alternatives like spring-energized PTFE seals or a high-temperature elastomer like FFKM.

Ultimately, choosing PTFE is a decision based on its unique ability to deliver consistent, multi-faceted performance where other materials cannot survive.

Summary Table:

| Property | Performance at High Temperature | Key Consideration |

|---|---|---|

| Thermal Stability | Excellent (Service temp up to 260°C / 500°F) | Melting point is 327°C (621°F) |

| Chemical Resistance | Unmatched, remains inert | Ideal for aggressive environments |

| Dimensional Stability | Maintains form and function | Softens near service limit |

| Mechanical Properties | Low elasticity, susceptible to creep | Fillers (glass, carbon) improve performance |

| Best For | Static seals in extreme heat/chemicals | Filled PTFE recommended for dynamic/high-pressure use |

Need a high-performance seal that won't fail under extreme heat and chemicals? KINTEK specializes in precision PTFE components, including O-rings, seals, and custom labware. We serve the semiconductor, medical, laboratory, and industrial sectors, offering custom fabrication from prototypes to high-volume orders. Our expertise ensures your seals deliver reliable thermal stability and chemical resistance. Contact our engineering team today to discuss your specific application requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the standard seat material for ball valves and why is it used? Discover the Ideal Choice for Your Application

- What are the main disadvantages of virgin PTFE products in fluid sealing applications? Overcoming Creep and Cold Flow

- What role do PTFE tri-clamp gaskets play in industrial applications? Ensuring Leak-Proof, Contamination-Free Systems

- What industries are PTFE gasket envelopes suitable for? Find the Perfect Seal for Demanding Applications

- What advancements are being made in recycling Teflon scrap? From Micronization to Upcycling

- What are the characteristics of fully PFA or PTFE lined butterfly valves? Maximize Corrosion Resistance & Reliability

- How do PTFE rotary seals compare to rubber seals? A Guide to Superior Performance in Extreme Conditions

- What are the unique properties of PTFE that make it suitable for CNC machining? Master Machining for Superior Components